Semi-Automatic vs Fully Automatic Dab Machines: Filling Machine Comparison for Wax & Oil

In this guide, we’ll compare semi-auto vs full-auto dab machines side by side and break down the key factors that matter most for real-world wax and oil filling.

Semi-Automatic vs Fully Automatic Dab Machines: Quick Comparison Table

Item | Vape-Jet Dab Dispenser (Semi-Automatic) | Longwill Dab Wax Filling Machine (Fully Automatic) |

Machine type | Semi-automatic jar filling + weight check | Fully automatic dab wax filling machine |

Primary use | Concentrate jar filling (e.g., 1g jars) | Dab/wax filling; supports jars and other formats (with fixtures) |

Throughput (claimed) | Up to 500 x 1g jars/hour | 2000–3000 sticks/hour (site also lists 20–30 pcs/min) |

Accuracy (claimed) | ±1% (with automated weight check) | ±0.01 ml (site also lists 0.01g) |

Reservoir / tank | 1L removable stainless reservoir | 1L oil tank |

Heating / viscosity approach | “No-to-low heat” + nitrogen-pressurized dispensing | Heated system, temperature range 0–120°C |

Control style | Semi-auto operation; integrated scale + auto-calibration | Touchscreen + PLC; motor/ball-screw control |

Best fit | Brands prioritizing jar filling + weight validation | Brands needing fully automatic precision + higher productivity |

What Are Semi-Automatic Weed Wax Machines?

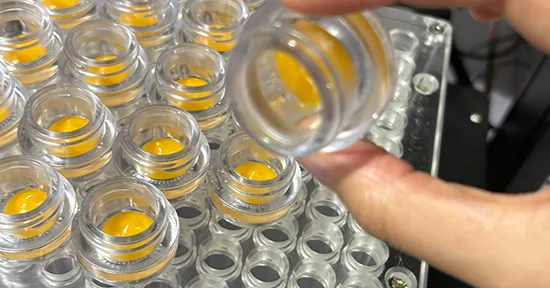

A semi-automatic dab filling machine is a solid upgrade from hand filling, improving consistency and efficiency while still keeping the operator involved. In most setups, the operator loads and removes containers, starts each cycle, and may verify or fine-tune the fill by volume or weight. Put simply, the dab machine handles controlled dispensing (often with heating), while the operator controls the pace and handling.

Semi-auto systems are often chosen for their flexibility. They’re well suited for smaller runs, frequent SKU changes, and jar-filling workflows where quick visual checks and hands-on adjustments are part of daily production. Since the system is typically less complex than a fully automated line, it’s also easier to maintain, easier to troubleshoot, and more budget-friendly.

For many teams, a semi-automatic weed wax machine is the practical next step—ideal for moving beyond syringes, supporting in-house dab wax filling, and increasing output without jumping straight into full automation.

What Are Fully Automatic Dab Filling Machines?

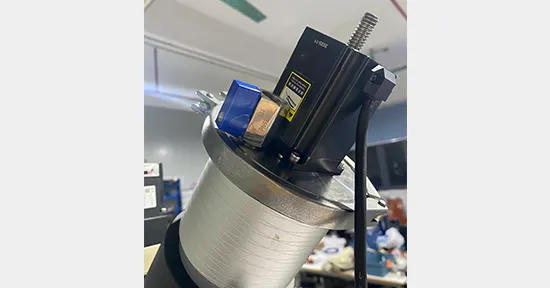

A fully automatic weed wax machine runs the filling process as a programmed sequence, so day-to-day production requires far less hands-on work. In a typical workflow, the operator sets key parameters—fill volume, temperature, speed, and positioning—loads the tray/jig (or fixtures), and starts the cycle. After that, the dab machine handles the rest: it moves into position, dispenses the preset amount, and repeats the same routine across the batch. Many systems add multi-nozzle filling to increase throughput while keeping results consistent from unit to unit.

What makes it “fully automatic” is the combination of control and stability behind the scenes. Most machines use PLC + touchscreen control to run repeatable cycles, precision motion components (rails and lead screws driven by a servo or stepper motor) to maintain accurate positioning, and a metered pump system to deliver consistent dosing. For thick wax and high-viscosity oils, temperature-controlled material paths are often included to keep flow steady and help reduce clogging, tailing, or slowdowns during longer runs.

Overall, a fully automatic dab filling machine is a strong fit for growing brands that need higher precision, higher output, less dependence on operator technique, and more consistent results across shifts.

Key Comparison Points for Wax & Oil

When you’re filling wax, rosin, and other thick oils, the “best” option usually comes down to how well the system manages viscosity, stays stable over long runs, and delivers a clean cut-off. Below are the factors that matter most in day-to-day production—whether you’re using a semi-auto setup or a fully automatic wax weed machine.

1) Viscosity Handling and Temperature Control

A semi-automatic dab machine can handle thick material well—especially if you like hands-on control—but results may vary more with operator pace and technique. Heating is sometimes simpler, such as primarily warming the reservoir. A fully automatic dab filling machine typically holds steadier output because it runs at a consistent rhythm and maintains controlled conditions. Multi-zone heating (tank + line/nozzle) is especially useful for preventing cooling, clogging, and tailing when viscosity shifts during a run.

2) Fill Consistency: Volume vs. Weight

Semi-auto workflows often involve more operator checks and may lean on weight verification, which can be ideal for jar filling where weight is the main QC point—though it can slow throughput. Fully automatic wax weed machines usually focus on repeatable dosing cycle-to-cycle; with stable positioning and metered dispensing, they tend to deliver tighter unit-to-unit consistency across larger batches. If you’re scaling, the key is consistency not only at startup, but also after pauses, refills, and longer runs.

3) Throughput and Labor Efficiency

A semi-automatic dab machine is generally much faster than hand filling, but output is still tied to people—starting cycles, handling containers, and keeping the pace moving. A fully automatic weed wax machine is designed to raise throughput without increasing labor at the same rate; once loaded and started, it can run steady batch cycles with less operator involvement. If labor is your biggest bottleneck, full automation is often the clearest path to more capacity.

4) Clean Cut-Off, Drips, and “Tailing”

Thick concentrates tend to string, so clean cut-off becomes a major differentiator. Nozzle diameter, heat stability near the tip, pump start/stop control, and repeatable motion all influence whether you get clean breaks or messy tails. Semi-auto can still be clean, but it’s more dependent on operator timing. Fully automatic systems typically synchronize motion and dispensing the same way every cycle, which helps reduce drip variation and keeps results more uniform across the tray.

5) Changeovers, Cleaning, and Multi-SKU Workflows

Semi-auto weed wax machines can be quicker to clean simply because the systems are often simpler and operators are already working hands-on. Fully automatic machines can also clean up fast when they’re designed with a short oil path, removable contact parts, and easy access to the reservoir and lines. Where full automation often wins is changeover consistency—saved programs and repeatable positioning make switching SKUs more predictable. No matter which route you choose, prioritize easy disassembly, low dead volume, and quick-change nozzles/fixtures if you run multiple products.

6) Flexibility: Hardware and Container Compatibility

Semi-automatic setups feel flexible because operators can adapt quickly to different jars or formats. A fully automatic dab machine can be just as flexible when the platform supports interchangeable trays/jigs, nozzle options, and simple parameter adjustments. If you fill a mix of carts, pods, pens, and jars, look for a system built around fixture swaps and adjustable positioning—not one locked into a single format.

7) Cost of Ownership and Scaling Path

Semi-automatic machines typically have a lower entry cost and straightforward maintenance, making them a solid upgrade from manual processes. Fully automatic systems cost more upfront, but they often reduce cost per unit at scale through higher throughput, steadier output, and less labor dependence. If you expect growth in the next 6–18 months, a fully automatic dab filling machine can become the more economical choice once labor savings and production stability start to compound.

Read more:

https://longwillmachinery.com/Blog/how-does-a-dab-filling-machine-work.html

Conclusion

There isn’t a one-size-fits-all answer—your best choice depends on your product type, batch size, staffing, and growth plan. A semi-automatic dab machine is often the practical step up from manual filling when you want flexibility and hands-on control, especially for smaller runs or frequent changeovers. A fully automatic dab filling machine is typically the better fit when you need higher output, tighter repeatability across shifts, and less reliance on operator technique.