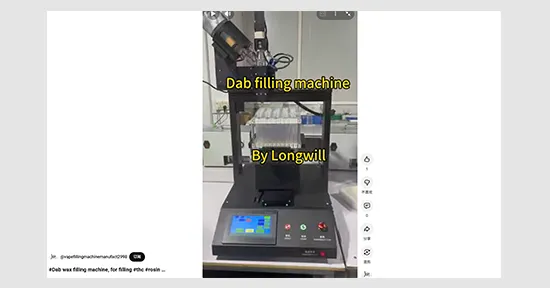

How Does a Dab Filling Machine Work?

A dab filling machine is one of the most practical tools for turning thick concentrates into clean, consistent finished products—especially when you’re filling cartridges, disposables, or pods at scale. Instead of relying on manual syringes and “by feel” dosing, these machines use programmed control, stable positioning, and repeatable dispensing to improve consistency and reduce waste.

Below, we’ll break down what a dab filling machine does, how the filling process works step by step, and what’s happening behind the scenes that makes the workflow truly automatic.

What a Dab Filling Machine Does

A dab filling machine is built to dispense precise, repeatable amounts of thick cannabis concentrates—such as rosin, wax, and other high-viscosity oils—into cartridges, disposables, pods, or containers. Rather than relying on hand-filled syringes, it turns the process into a more controlled, consistent workflow, helping each unit come out the same.

With accurate metering and steady positioning, the machine helps improve dosing consistency, reduce mess and product loss, and keep batch output uniform. Many models also use temperature control to maintain smooth flow, which can reduce clogging and nozzle “tailing,” making production cleaner and more efficient while supporting better quality control.

How a Dab Machine Works

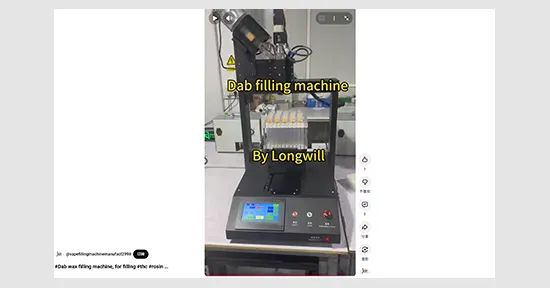

Touchscreen setup and parameter selection

A dab machine usually starts with a quick setup on the touchscreen. The operator chooses a program, confirms the target fill volume, and adjusts basic motion and cycle settings—how the head moves, where it pauses, and how the sequence repeats. Once those parameters are saved, the dab machine can run the same routine consistently, which is a big part of how it improves repeatability compared with manual filling.

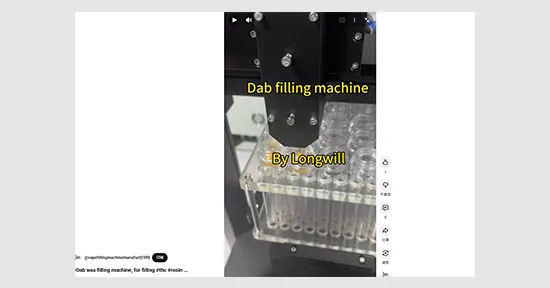

Nozzle alignment over the tray/jig

Next, the dab machine moves to the filling station. A multi-needle nozzle head lines up over a tray/jig that holds each unit in a fixed position. The tray does more than keep parts organized—it standardizes spacing and height so the nozzles land in the right place every cycle. That helps reduce misalignment, keeps the work area cleaner, and supports a smoother workflow. In this setup, the machine references practical capacity specs like a 0.2–6 ml filling range and a 2.5 L oil tank, giving flexibility for different products while cutting down on refill interruptions.

Multi-nozzle filling for higher efficiency

With everything aligned, the dab machine dispenses into multiple units at once—5 pieces per cycle in this example. This multi-nozzle approach boosts throughput while keeping results more uniform, since each nozzle follows the same programmed movement and dosing logic. The cycle itself is simple: move into position, dispense the set amount, then lift and reset for the next pass. Because the machine dab workflow controls both motion and dosing, it reduces common manual issues like inconsistent timing, uneven pressure, or slight hand placement differences.

Continuous batch filling workflow

From there, the dab machine runs through the tray in a steady batch routine, repeating the same position-and-dispense sequence until the tray is finished. The workflow stays straightforward: load a tray, run the cycle, and let the machine dab maintain consistent output across the batch. The real benefit is predictability—repeatable alignment and controlled dispensing help reduce under/overfills, minimize interruptions from misplacement, and avoid slowdowns caused by constant manual handling. For growing operations, this kind of steady batch rhythm is often what makes daily production easier to manage and more consistent shift to shift.

If you want to view the YouTube video, you can click on it:

https://www.youtube.com/shorts/SaWJxKf724I

What Makes the Process “Automatic” in a Machine Dab

Tray/Jig Positioning (Consistent Alignment)

In a machine dab, the tray/jig is more than a place to set hardware—it’s a positioning system. Each cartridge or device sits in a fixed pocket with consistent spacing, height, and orientation, so the machine can return to the same fill points every cycle. That repeatable alignment helps the nozzle head land accurately, reducing missed targets, splashing, and the small placement errors that often create mess and rework during manual filling.

Multi-Nozzle Dosing (Higher Throughput)

Multi-nozzle filling isn’t only about speed—it also helps standardize output. Instead of filling one unit at a time, the dab machine dispenses into several units simultaneously, increasing output per cycle while keeping the workflow smooth. Because each nozzle follows the same programmed motion and dosing routine, fills tend to be more uniform across the tray. It also cuts down on the constant stop-and-go handling that slows production in single-nozzle or hand-filling setups.

Program-Based Control (Repeatable Workflow)

What makes the process truly automatic is the repeatable sequence behind it. Operators set key parameters on the touchscreen—like volume targets and cycle behavior—and the machine dab executes the same steps in the same order every time. That consistency reduces guesswork and operator-to-operator variation, which is especially useful when multiple people run the line or when you need the same results across shifts. It also makes changeovers easier because you’re adjusting a known program rather than dialing everything in by feel.

Repeatability (Less Variation, Less Waste)

Once positioning and dosing are standardized, many common sources of variation drop away—uneven timing, inconsistent pressure, small hand movements, or messy cutoffs. In daily production, that usually means fewer drips and strings, fewer under/overfills, and less product lost during restarts or brief pauses. Over longer runs, repeatability is what keeps yield predictable: cleaner fills, fewer rejects, and less time spent correcting small issues that add up fast.

Conclusion

A dab filling machine works by combining three core elements: program-based control, precise alignment with trays/jigs, and repeatable multi-nozzle dosing. Together, these features help deliver cleaner fills, more consistent results, and a smoother production rhythm—especially across longer runs and multiple shifts.