Oil tank: 1L

Oil filling accuracy: 0.01g

Output: 2000-3000 sticks / hour,single needle

Program capacity 0.1g-unlimited

Key Feature: High precision,Fully automatic,Increased productivity

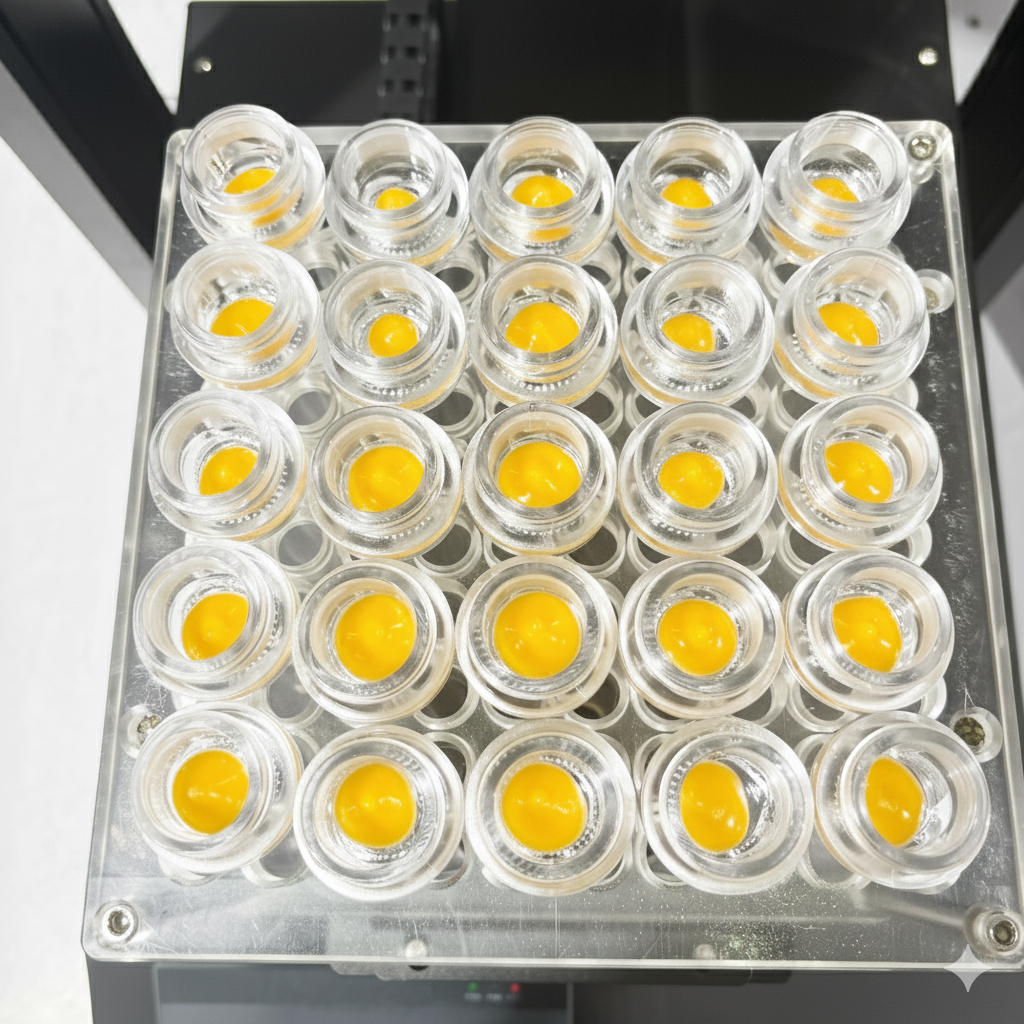

Material: cbd/thc/rosin/resin dab and concentrate

Filling Accuracy: ±0.01ml

Temperature: 0–120°C

Voltage: 110V-220V

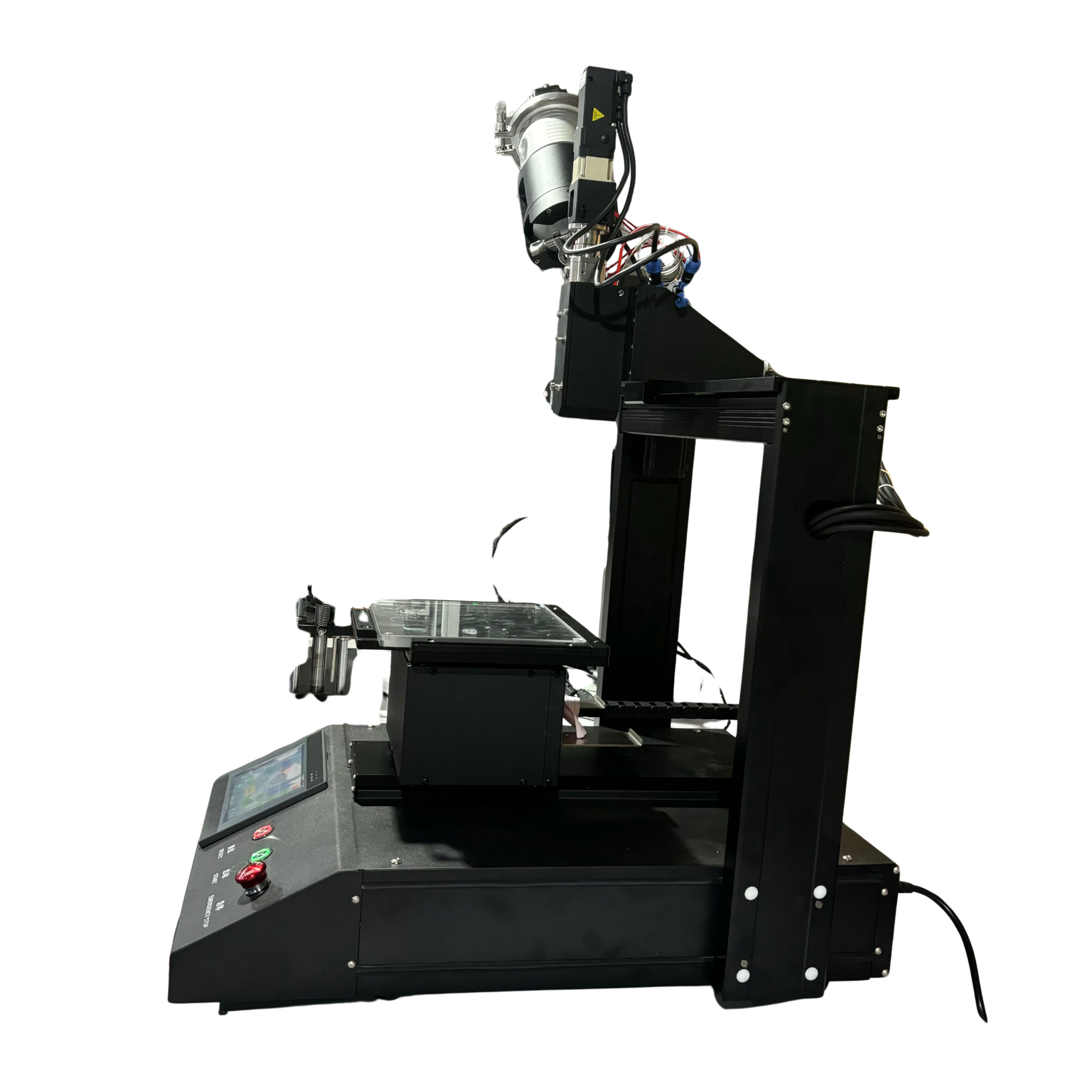

height can be adjusted, Suitable for ≥2mm diameter 5-100mm height jar

Panel control: Motor +ball screw, Touch screen+PLC+ self-programmed program

Output Productivity: 20-30 pcs/mins, 1200pcs/hour

How Does a Dab Filling Machine Work?

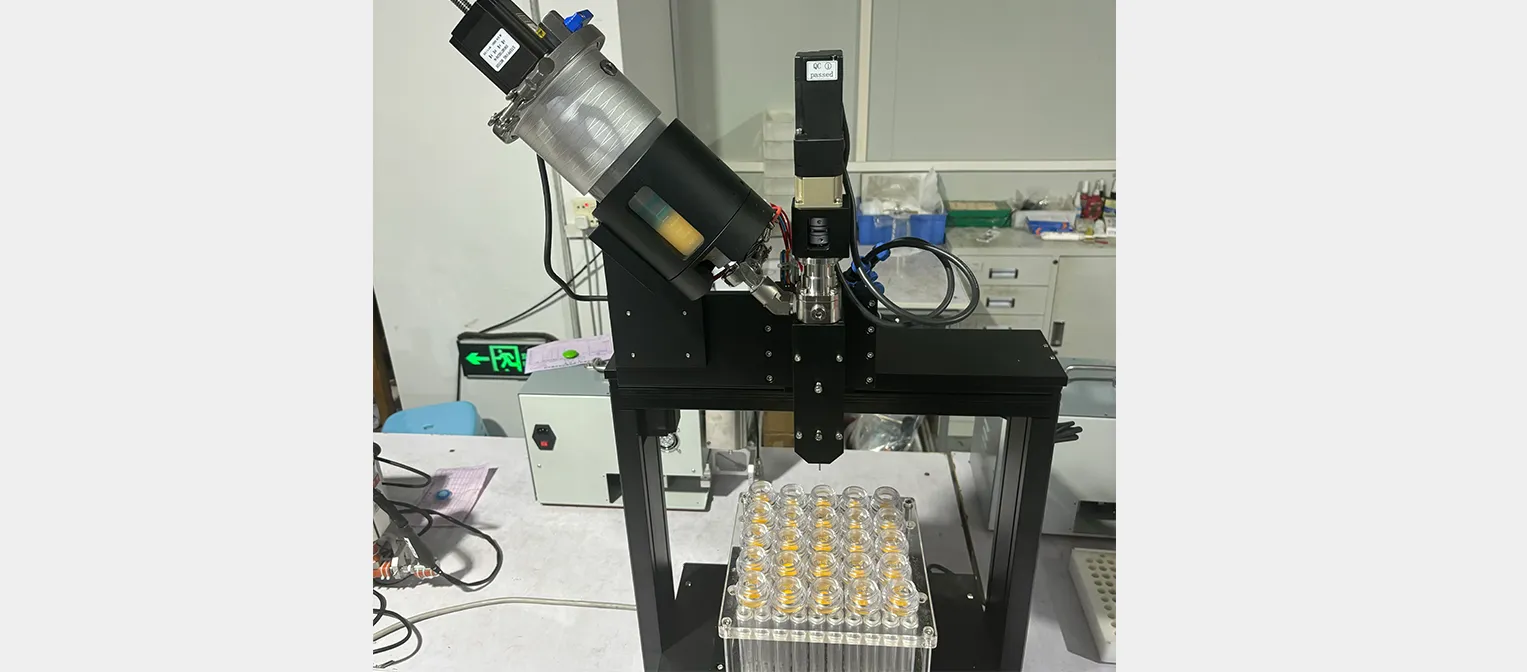

A dab filling machine uses programmed control, precise positioning, and consistent metering to dispense thick concentrates into cartridges,

disposables, or pods with repeatable results.Rather than relying on “by-feel” syringe filling, the operator enters the target fill volume and

cycle settings on the touchscreen, and the machine runs the same sequence each time.

Once started, the nozzle head positions over a tray/jig that holds every unit in a fixed location, then delivers the preset amount

—often through multiple nozzles to increase throughput.It repeats this cycle across the tray for smooth batch production, helping improve fill uniformity,

reduce mess and material waste, and keep output stable throughout longer runs.

If you’d like a deeper breakdown of how the machine works, click “How Does a Dab Filling Machine Work?” to explore the full process and

find the answers you’re looking for.

Custom or specialty containers for a Dab Filling Machine

Multiple jar sizes can be supported with simple adjustments, such as changing the tray/jig setup and fine-tuning positioning and fill settings.

This makes it easy to switch between different container diameters and heights without rebuilding the entire workflow, helping you run standard

and specialty jars on the same machine with minimal downtime.

Why Choose Longwill Machinery Dab Making Machine ?

Designed for High-Viscosity Materials

Handles thick concentrates without excessive pulling or dripping.

Improved Weight Consistency

Helps reduce overfill and minimize material loss.

Faster Than Manual Filling

Increase output without increasing headcount.

Easy to Learn, Easy to Run

No engineering background required.

Faster Cleaning & Changeover

Designed with cleaning efficiency in mind for multi-SKU operations.

Built for Real-World Cannabis Operations

This weed wax machine is ideal for:

1.Small to mid-size cannabis brands

2.In-house dab wax filling

3.Teams scaling beyond manual processes

Brands looking for consistency without losing flexibility

How to Choose a Dab Filling Machine

For these teams, the “right” dab filling machine is one that delivers consistent fills while staying easy to operate every day. Start with the fundamentals that matter

most for solventless concentratesstrong viscosity control and adjustable, stable heating. A compact, heated material path helps keep oils flowing smoothly,

while the right metered pumping system supports repeatable dosing.Pair that with wide-gauge, interchangeable nozzles and

you’ll be better equipped to handle different textures and hardware formats without frequent clogs, tailing, or slowdowns.

Then choose a dab filling machine that matches your growth plan. Prioritize accuracy that holds up over a full shift, throughput that can scale with demand,

and a design that makes cleaning andchangeovers faster—because downtime becomes expensive as volume increases.

If you run multiple SKUs or container types, look for flexible trays/jigs and simple setup routines thatmake switching formats painless.

Finally, solid manufacturer support—clear documentation, accessible spare parts, and responsive troubleshooting—

helps keep production steady as your operation expands.

If other brands’ fully automatic systems feel overpriced, Longwill Machinery offers a smarter alternative—our fully automatic dab filling machine delivers the best value without sacrificing performance.

Manual vs. Dab Machine Filling (Simple Comparison)

Filling Method | Speed | Consistency | Labor | Material Loss |

Hand Filling | Low | Low | High | High |

Syringe Filling | Medium | Medium | High | Medium |

Dab Wax Filling Machine | High | High | Low | Low |

Dab Machine Common Questions

1.Is this machine dap fully automatic?

Yes. It’s fully automatic—designed to deliver consistent, repeatable filling with minimal manual operation, while keeping setup and cleaning straightforward.

2.Can it handle different wax consistencies?

Yes. Temperature and flow can be adjusted based on your material.

3.How hard is it to clean?

Cleaning is significantly faster than syringes or modified paste fillers.

4.Can you customize it for my jar size?

Yes. We support customization based on your container and filling requirements.

Ready to Upgrade Your Filling Process?

If you’re filling dab wax by hand today,

this machine helps you take the next step — without overcomplicating your operation.

Tell us what you’re filling. We’ll recommend the right setup.

Please refer to customer case

Please feel free drop us a call or message, our professional account manager will feedback in 5 mins!

Contact us now!