What to Look for in a Filling Machine A Buyer’s Guide for Automation

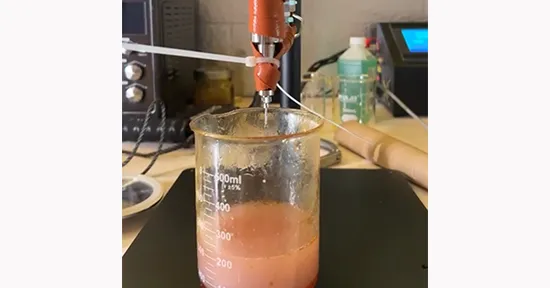

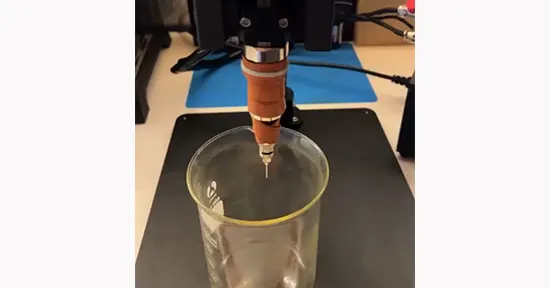

Choosing the right cart filling machine isn’t just a purchasing decision—it’s a strategic one. As product lines expand, viscosities change, and demand accelerates, guessing your way through equipment selection can turn into an expensive bottleneck. The tricky part is that most filling machines look similar on paper, yet behave completely differently once they meet real-world oils, cartridges, or bottling formats.

That’s why operators across Reddit—from vape labs to pharmacies to cosmetic producers—often share the same advice: understand your product, your workflow, and your long-term needs before investing in automation. A well-chosen filling machine can transform your line into a predictable, scalable system. A poorly matched one can slow everything down.

In this guide, we break down the key factors to consider when choosing a cart filling machine—precision, flexibility, throughput, clean-ability, compliance, and support—anchored by insights from real users who’ve learned these lessons the hard way.

First Things First: What Are You Filling?

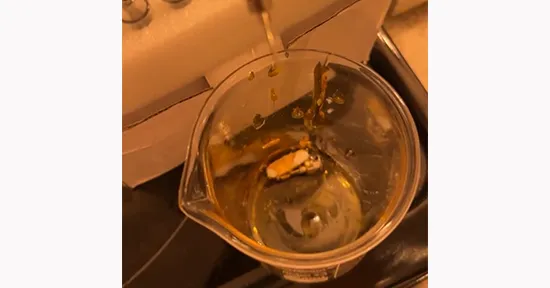

Before you start comparing prices or model names, get very clear on what you’re actually asking the machine to handle. Simply saying you “fill liquid” is far too broad. Different products behave very differently in a cartridge filling machine, and the more precise your understanding, the better your purchase decision will be.

Consider at least these factors:

Viscosity:

Is the product thin like water, syrupy, or closer to a paste? High-viscosity oils, gels, and creams often require heated lines, larger nozzles, or piston-style pumps rather than peristaltic systems.

Temperature sensitivity:

Can the product tolerate gentle heat to improve flow, or would heating damage terpenes, active ingredients, or volatile compounds?

Particles or inclusions:

Do you have suspended solids, crystals, or microcapsules that might clog narrow nozzles?

Container details:

Are you filling bottles or cartridges? Glass or plastic? 2 oz or 2 mL? Wide mouth or needle-sized opening? Stability on a conveyor or tray also matters.

Target fill volume + tolerance:

Do you need ±2% accuracy, or something much tighter?

One Redditor perfectly captured this early-stage challenge when asking for help:

“We are looking for a table top or relatively small machine that is either manual or semi-automatic to cartridge filler bottles from 2oz–8oz… wasn’t sure if anyone had personal experience…”

Behind that question is a real truth: most cartridge filler machines are marketed like they work for everything, but real products aren’t generic. A thick cream does not behave like a thin tincture, and a squat bottle won’t handle like a tall, narrow cartridge.

Before talking to vendors, define:

Your current products (viscosity, heat limits, container specs)

Near-term formulas or new SKUs you expect

Your regulatory or quality environment (pharma, cosmetics, vape, food, etc.)

The clearer your needs, the faster you can eliminate incompatible equipment and find a cart filling machine built for your actual workflow.

Precision: Because Every Drop Counts

Once you know what you're filling, the next question is: how precisely must the machine hit your target volume?

Precision isn’t just an engineering term—it directly influences:

Cost of goods: Even a small overfill adds up, especially with high-value formulas.

Label accuracy & compliance: Underfilling risks regulatory trouble and unhappy customers.

Customer trust: People notice when one unit feels lighter than another.

One Reddit user put it bluntly when describing low-end machines:

“Cheaper models will break on you at industrial level within a few days.”

That failure often includes drifting fill volumes or poor repeatability.

When evaluating precision for your cartridge filler machine, look deeper than marketing brochures:

Request the repeatability spec (e.g., ±1% at a certain volume + viscosity).

Confirm the dosing method: volumetric (piston/gear pump) vs. time-based—the latter varies more with viscosity changes.

Check for easy calibration tools that let you run test cycles into a scale or cylinder.

Look for basic run logs or data, even on entry-level machines, to verify consistency over time.

If your product is expensive, regulated, or quality-sensitive, precision directly influences your bottom line—and your brand reputation.

Flexibility = Long-Term Value

Buyers often focus on today's needs, forgetting how quickly product lines evolve. New viscosities, new container formats, seasonal formulas—all of these can turn a narrowly designed machine into a limitation.

A pharma Redditor shared a perspective that applies across industries:

“We’ve been using a Parata Max for the past 5 years… it’s been very solid… support has been good when we needed it.”

The takeaway isn’t the model—it’s durability and versatility.

When evaluating flexibility, ask:

How easy is changeover? Minutes or hours? Tools or tool-less adjustments?

Are nozzles, trays, or guides interchangeable? Or are you locked into one format?

Can the machine handle a wide viscosity range? Some oils thicken seasonally or with terpene changes.

Is the system modular? Can you add more fill heads, conveyors, or capping modules later?

Flexibility doesn’t mean complexity. You want a cartridge filling machine that adjusts smoothly—not one that needs an engineer every time you switch products. The more adaptable the platform, the better the ROI over time.

Throughput: Match Your Pace

Throughput often looks impressive on spec sheets—until you realize those numbers assume perfect conditions. Real throughput changes once you factor in viscosity, operator skill, changeovers, and cleaning.

Start with your actual needs:

How many units per hour/day do you need now?

What about 12–24 months from now?

How many shifts can you realistically run?

Reddit threads discussing high-viscosity creams and gel filling machines reflect a common pain point: manual or semi-manual systems simply can’t keep up once demand increases.

When evaluating throughput for a cartridge filling machine, consider:

Are throughput claims based on your viscosity, or just water in a demo?

How much does speed drop when you include cleaning and setup time?

Can you scale to multiple nozzles later?

Does accuracy hold at higher speeds, or must you slow down to stay within spec?

Your goal isn’t the fastest machine—it’s the right speed with room to grow, without turning your filling step into the next bottleneck.

Clean-ability + Compliance

Cleaning is where many “good deals” quickly turn into expensive mistakes. Oils, botanicals, creams, and extracts cling to surfaces, meaning poor clean-ability equals more downtime and higher contamination risk.

This is one of the most common Reddit complaints about budget machines: they perform until you have to clean them—then you discover the real cost.

Evaluate clean-ability honestly:

Is disassembly quick and intuitive? Or does it feel like taking apart a watch?

Any dead legs or tight pockets? These trap residue and complicate sanitation.

Are contact surfaces made from proper materials? Stainless steel, compatible seals, etc.

Can you use CIP or SIP? Or is everything manual teardown only?

Does the vendor provide cleaning SOPs and maintenance guidelines?

If you’re in a regulated environment, you may also need:

Documented cleaning records

IQ/OQ validation from the vendor

Material certificates and detailed schematics for audits

A cart filling machine that’s fast to clean and easy to verify will save hours of labor and reduce contamination risks for years.

Support + Training: You’re Not Alone

Even the most advanced cart filling machine won’t deliver its full value without proper training, maintenance, and responsive support. And when something breaks, every hour counts.

A Redditor in a pharmacy automation thread highlighted this perfectly:

“We had both printers out… missed an entire day of work because they just don’t have the employees.”

Downtime is expensive—lost output, overtime, delayed orders, damaged customer trust.

When comparing vendors, evaluate support as seriously as hardware:

Training: On-site or virtual? For both operators and maintenance staff?

Parts availability: Are common wear parts stocked and affordable?

Tech support: Do they offer real human help, in your time zone?

Service plans: Preventative maintenance or emergency service options?

Upgrade path: Will the vendor support expansions or future product changes?

A reliable support structure turns inevitable breakdowns into quick recoveries—not costly crises.

Read more:

Conclusion

A cart filling machine is more than a piece of equipment—it’s the backbone of your production workflow. When chosen well, it delivers tighter precision, smoother operations, faster throughput, and a level of consistency that manual processes simply can’t match. But the right machine isn’t defined by price or popularity; it’s defined by how well it fits your product, your pace, and your future growth.