Boosting Vape Cartridge Production: Smart Solutions for Efficiency and Safety

In a crowded vape market, efficiency, consistency, and safety aren’t just nice-to-have—they’re what separate growing brands from struggling ones. As cartridge hardware, oil formulations, and order volumes evolve, old methods like hand-filling with syringes and twisting caps by hand simply can’t keep up.

This article explores these trends in depth, showing how smart automation and modern vape cartridge filling machines can significantly boost production capacity, reduce human error, and make your line far more stable and predictable.

Why Press-Down Capping Is Becoming the New Standard

Twist-on caps used to be the default for sealing vape cartridges. They worked well enough when hardware was simpler and production volumes were lower. But as cartridge designs, materials, and oil formulations have evolved, press-down capping has become the better fit for modern production lines.

Compared with hand-twisting, press-down systems give manufacturers several important advantages:

Stable, repeatable sealing force

Each cartridge is capped with the same pressure, which greatly reduces slow leaks, loose caps, and random hardware failures in the field.

Smoother, faster workflow

Operators spend less time wrestling with individual cartridges and more time keeping the line flowing. Output goes up without the feeling of rushing or cutting corners.

Designed for today’s cartridges

Many newer cartridges are built around a press-fit closure. Forcing a twisting motion on those designs can stress internal parts or cause slight misalignment that only shows up later as a problem.

Less strain on operators

Taking away repetitive twisting helps protect wrists and hands, so operators can maintain consistency over long shifts without burning out.

More controlled, safer motion

A guided press keeps both force and alignment predictable, which is especially important when working with hot, thick oils or delicate glass hardware.

For thick, high-viscosity oils or more sensitive formulations, a reliable seal isn’t a “nice to have” — it’s what separates a stable product from costly returns and complaints. By moving sealing from manual feel to a controlled press, press-down systems remove one of the biggest sources of variation in cartridge production: inconsistent manual capping.

The Problem With Manual Filling

Manual filling sounds simple enough: heat the oil, pick up a syringe, and fill each cartridge one by one. For small test runs or boutique batches, that approach can get the job done. But as soon as you’re dealing with hundreds or thousands of cartridges, the weaknesses start to show. Fill levels vary from cartridge to cartridge, the line slows down as operators get tired, and people hit their physical limits long before the work is finished. With fatigue comes more misjudged fills, small spills, and uneven product from batch to batch.

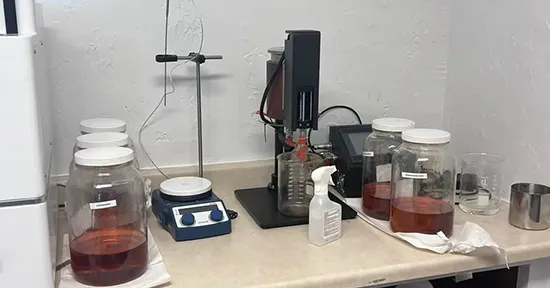

The impact on safety and quality is hard to ignore. Working with hot, viscous oil in open containers and handheld tools raises the risk of burns, contamination, and unnecessary waste. A single slip can mean an overfilled cart, a short fill that fails QC, or oil splashed across tools, tables, and floors. Over time, these“little issues”turn into real cost: higher defect rates, more rework, and more customers noticing inconsistency. It’s not a question of skill—manual methods simply aren’t designed for high-volume, high-precision work.

This is where vape cart filling machines really change things. Instead of relying on an operator’s judgment for every single fill, automated systems keep temperature, dose volume, and flow rate under tight control. As production scales up, these machines remove the bottlenecks created by hand-filling, allowing teams to move more units through the line, hold specs much tighter, and reduce safety incidents—without pushing staff past their limits.

Time to Upgrade: Automated Vape Cartridge Filling Machines

An automated vape cartridge filling machine addresses nearly every limitation of manual production. Instead of constantly fighting inconsistent fills, operator fatigue, and preventable safety risks, manufacturers gain a controlled, repeatable process that’s actually built for high-volume work. As output targets increase, making the jump from syringes to a dedicated vape cartridge filling machine stops being a “nice upgrade” and quickly becomes a practical requirement for staying competitive.

Modern systems typically offer several key advantages:

Precision metering

A quality vape cartridge filling machine is designed to hit the same dose, every single time. Rather than depending on an operator’s timing, grip strength, or visual judgment, the machine dispenses a programmed volume with fine-level accuracy. This helps keep each cartridge within the target fill range, reduces costly overfill and product giveaway, and makes it much easier for QC to verify that batches are on spec without constantly rechecking and adjusting the process.

Stable, intelligent temperature control

Thick, viscous oils are very sensitive to temperature changes. If they cool down, flow slows and fills become inconsistent; if they get too hot, you risk damaging the active compounds or terpenes. With built-in heating elements and smart temperature management, a vape cartridge filling machine keeps oil at a steady, optimized temperature throughout the run. That means smoother flow through lines and needles, fewer clogs, less stop-and-start downtime, and better protection for sensitive formulations like distillates, terpene-rich blends, and CBD oils.

High throughput without compromising precision

Manual teams almost always slow down as volumes rise and fatigue sets in. An automated vape cartridge filling machine, by contrast, is built to maintain pace and accuracy over an entire shift. Depending on the model and setup, production can scale from a few hundred to several thousand cartridges per hour. The real value isn’t just hitting a higher number—it’s being able to sustain that level of throughput while still meeting tight quality standards and without overloading your staff.

Cleaner and safer workflows

By reducing direct contact with hot oil and fragile cartridges, a vape cartridge filling machine lowers the risk of burns, spills, and accidental contamination. The more enclosed, organized layout helps keep oil where it belongs—inside the system and the cartridges—instead of on tables, gloves, and floors. Operators can spend their time supervising the process, checking parameters, and managing changeovers rather than wrestling with sticky syringes and open containers. The result is a cleaner, safer, and more ergonomic work environment.

Reliable consistency batch after batch

Once you’ve dialed in the ideal combination of temperature, fill volume, and flow rate, the vape cartridge filling machine repeats that setup with the same precision run after run. That consistency reduces variation between cartridges, lowers defect and reject rates, and ensures that customers have the same experience each time they buy your product. Over time, this kind of reliability doesn’t just make production easier—it becomes a core part of how your brand earns and keeps trust in the market.

For growing operations or teams trying to increase output without constantly adding headcount, investing in an automated vape cartridge filling machine is no longer just a convenience. It’s rapidly becoming a cornerstone of efficient, professional manufacturing. By turning filling from a fragile bottleneck into a stable, scalable process step, it helps you produce more, waste less, and deliver a consistently better cartridge to your customers.

Work Smarter With the Right Cart Filling Machines

Once you’ve seen what an automated vape cart filling machine can do on paper, the numbers alone make a strong case. But the impact becomes much more real when you hear it from the people standing at the line every day. On forums like r/vapeproduction, operators keep coming back to the same point: once you move from syringes to a proper cartridge filling machine, you really don’t want to go back.

As one user shared:

u/bench_op_92

“We finally switched from manual syringes to a legit cart filling machine last year and our whole workflow changed overnight. No more guessing fill levels, no more scorched oil from overheated beakers, no more fighting clogged syringes. Accuracy went up, waste went down, and it’s just a safer setup for the crew.”

Comments like this highlight what the metrics already tell you: upgrading to the right cartridge filling machine isn’t just about buying another piece of equipment. It’s about reshaping your workflow around something more precise, safer for your team, and far easier to scale as demand grows.

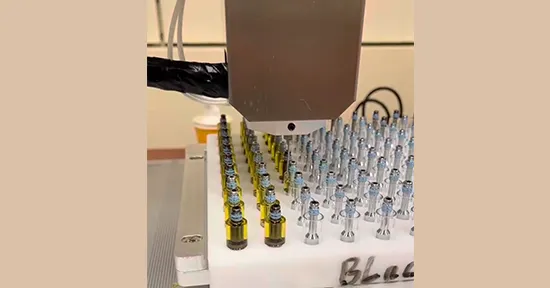

What About Loading? Pre-Loaded Vape Trays = Huge Time Saver

One of the biggest hidden time wasters in cartridge production isn’t filling or capping—it’s the repetitive job of loading, lining up, and moving empty (“naked”) cartridges between stations. Done by hand, operators spend a lot of time fixing tipped carts and re-organizing trays just to keep things moving. Even with a solid vape cartridge filling machine, this step can quietly become the bottleneck.

This is where pre-loaded vape trays really help.

They:

Cut setup time

Pre-loaded trays arrive already staged for your vape cartridge filling machine, so operators can drop them straight into the workflow instead of hand-loading every row.

Keep everything aligned

Each cartridge sits in its own pocket, staying upright and in position. Filling needles, capping tools, and inspectors can work without constant stopping to straighten carts.

Smooth handoffs between stations

The same tray moves from filling to capping to inspection—no repacking, no reshuffling—making the process simpler and faster.

Support a cleaner, more ergonomic workspace

Fewer loose cartridges and less “emergency fixing” mean a tidier bench and more comfortable, repeatable motions for operators.

Paired with an automated vape cartridge filling machine and press-down capping, pre-loaded trays help create a smooth, continuous flow that cuts downtime, relieves bottlenecks, and keeps the line running efficiently.

One Operator. 9× the Output.

This is where the power of smart automation really starts to show.

With the right setup—an automated vape cartridge filling machine, efficient capping, and organized trays—one operator can:

Oversee the filling process

Keep trays moving between stations

Handle capping or press-down sealing

Perform basic visual checks and QC

—all without constantly pausing just to catch up.

In many facilities, this kind of streamlined workflow delivers several times the output of a fully manual setup, with some reporting up to 9× higher throughput, depending on the equipment and the type of oil being filled.

And it’s not only about speed. Automation also brings:

More output from the same team

Fewer errors and rejected units

Lower labor cost per cartridge

More consistent product, batch after batch

Put simply, a well-designed vape cartridge filling machine doesn’t just make production faster—it makes the entire line more efficient, predictable, and scalable.

Conclusion

As demand continues to rise, sticking with purely manual processes quickly becomes a liability. By adopting automated vape cartridge filling machines, press-down capping, and pre-loaded trays, manufacturers can transform filling and capping from fragile bottlenecks into stable, scalable parts of the operation.