Longwill- Cannabis Oil Filling

Machine Manufacturer

Efficiency and Precision,

Efficiency and Precision,

Saving you More.

Saving you More.

Main Product Series

Main Product Series

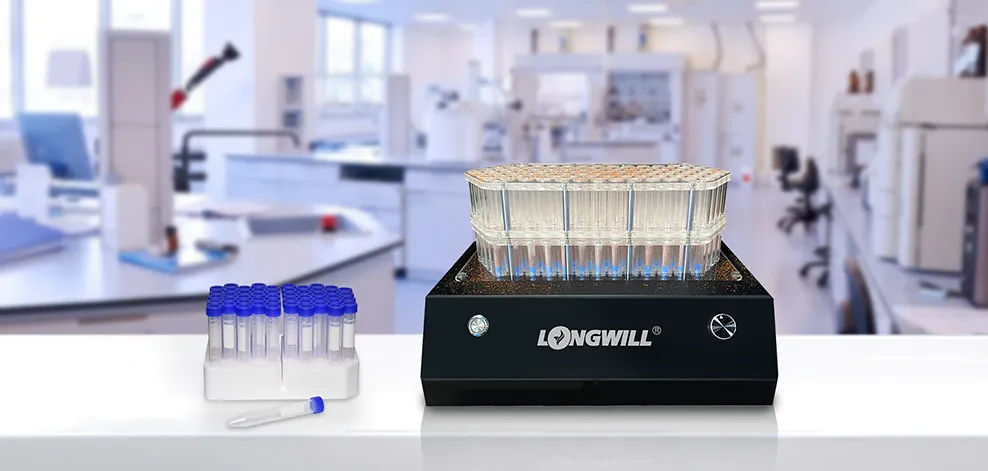

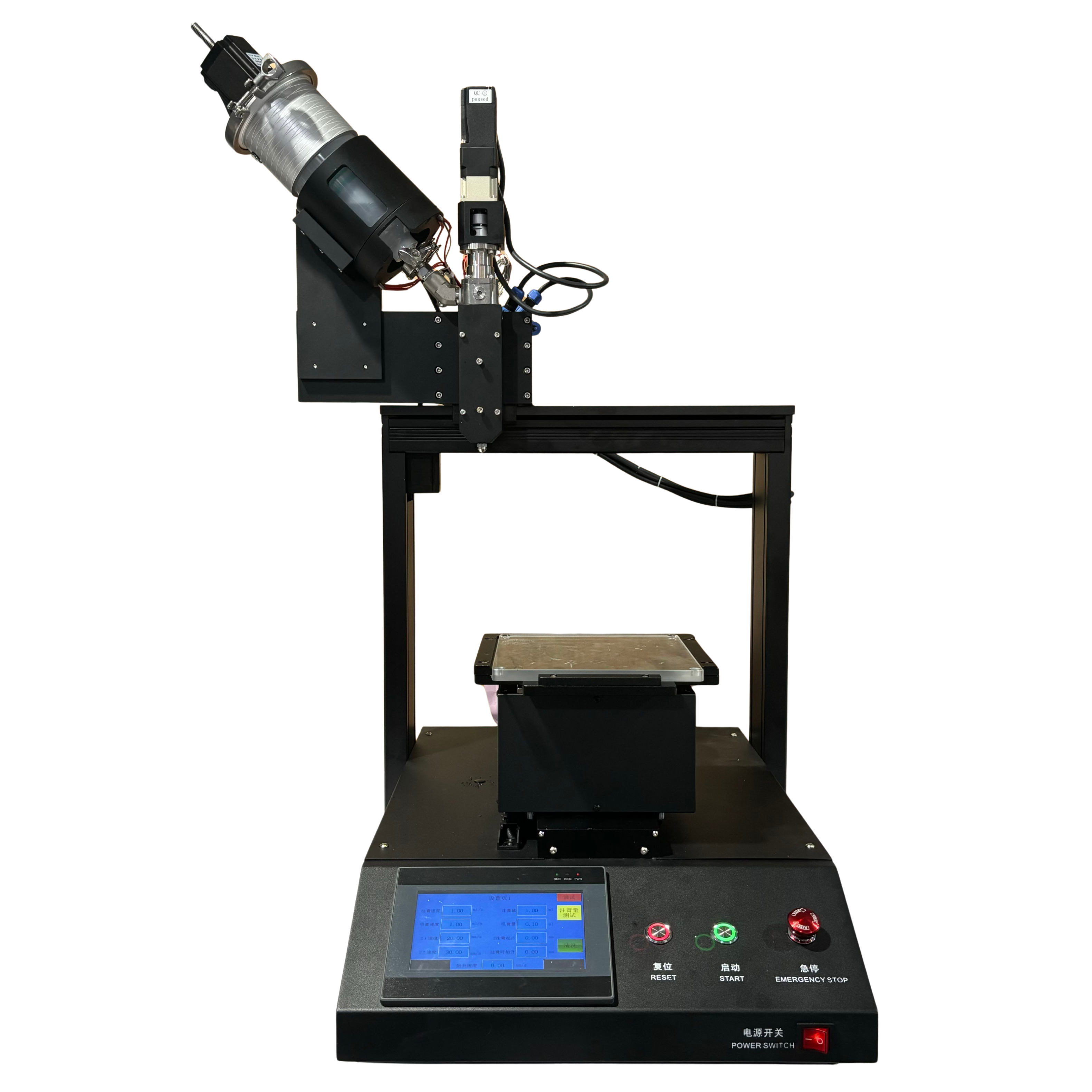

Dab wax filling machine

This dab filling machine is a high-precision, fully automatic solution for thick concentrates like wax and rosin. Built to reduce dripping, it’s a reliable dab making machine for consistent, high-throughput filling in cartridges, disposables, pods, and ja

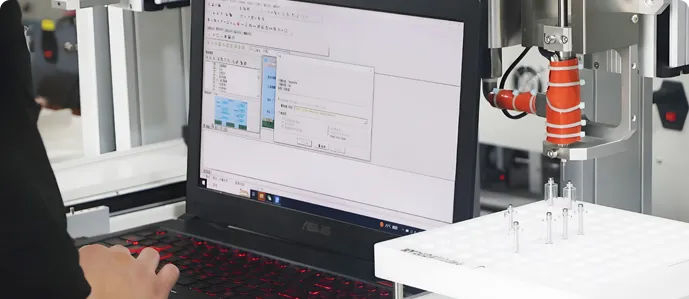

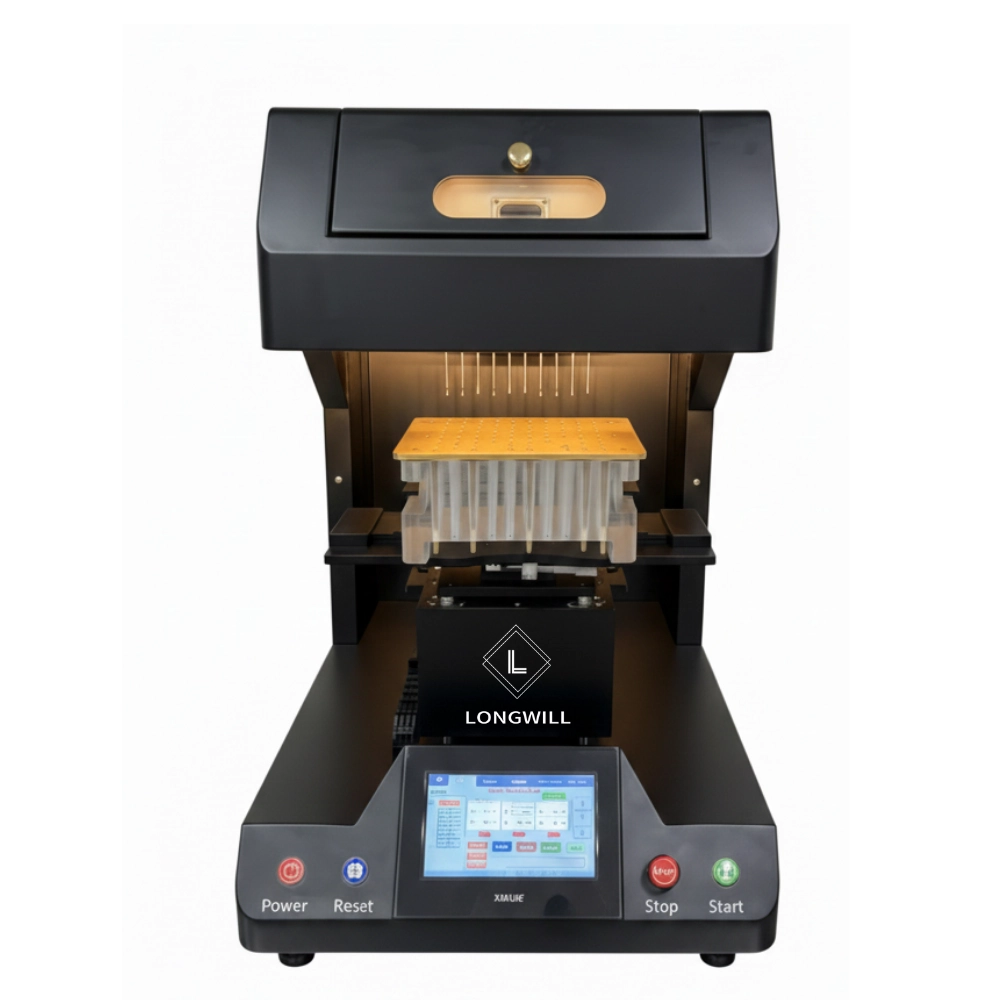

Fully Automatic Dual Oil Tank Cartridge Filling Machine

Fully automatic dual oil cartridge filling machine with dual tanks and nozzles. Supports single flavor and dual flavor CBD vape cartridges with high accuracy.

Amount of oiling: 0.2-7ml + 0.2-7ml

Oil tank: 800ml + 800ml

Oil filling accuracy: ±0.01ml

Output: 800-1200 sticks / hour

Power supply: AC220V/110V

Drive mode: Stepper motor + rail drive

Temperature range: 0-120 celsius

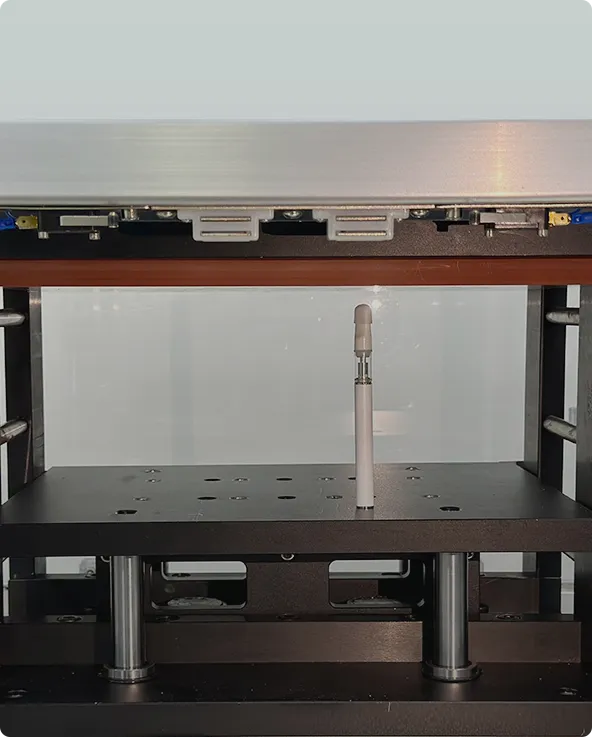

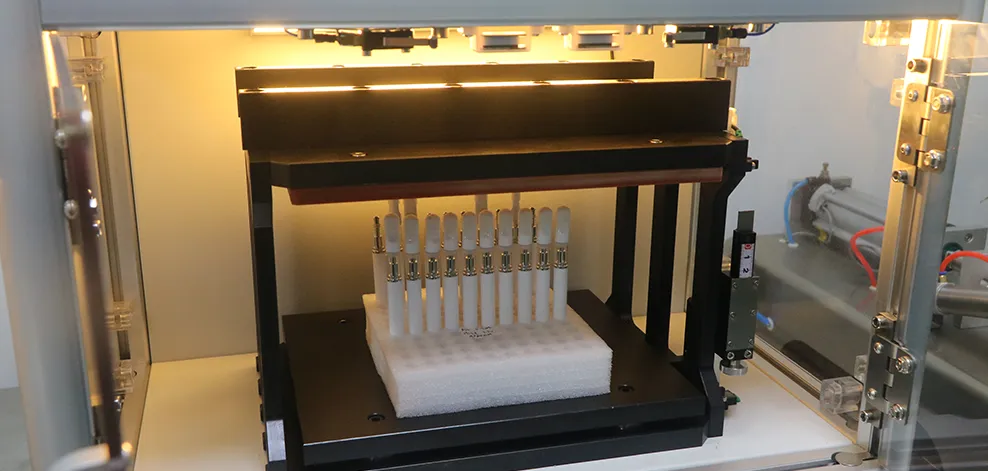

10 nozzle preroll infusion machine

High efficiency 10 nozzle preroll infusion machine designed for infused prerolls. Precise oil dosing from 0.2ml to 1ml. CE & FCC compliant filling solution.

Our Services

At Longwill, we offer more than just filling and capping machine solutions.

We provide comprehensive OEM/ODM services tailored to your needs,

outstanding after-sales support, and fast delivery to ensure your business runs smoothly and efficiently.

About Longwill

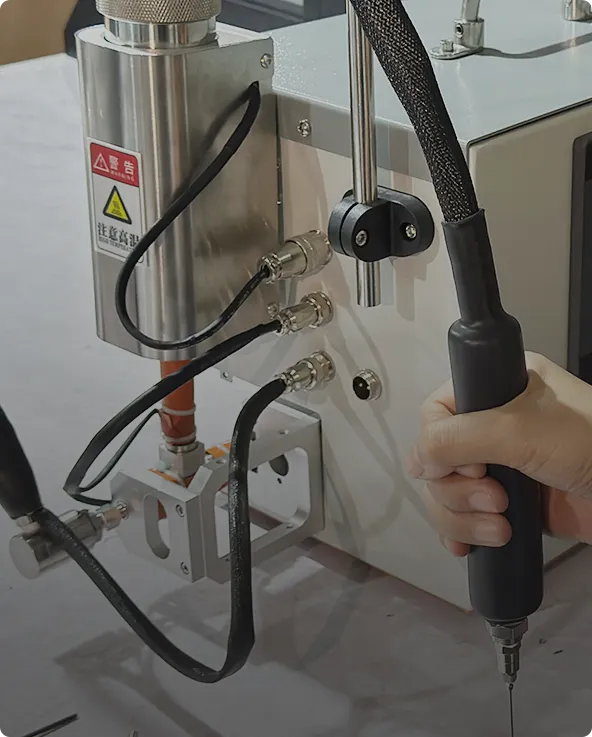

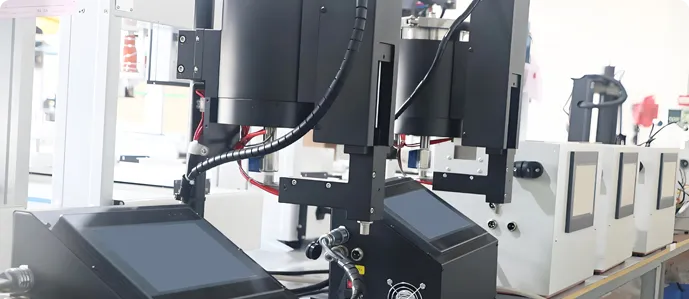

Longwill Technology is a reliable company. We focused on providing high-quality cartridge filling machines, capping machines, pre-roll machines, dab dispenser machines, pre-roll infusion machines and more since 2014.

Our team of highly skilled professionals is dedicated to delivering exceptional products and services that exceed our clients’ expectations. Led by James, our Chief Engineer, who has over 20 years of experience in the machinery industry. we are committed to providing innovative and efficient filling and capping solutions to clients worldwide.

About Us

Our Mission

At Longwill, our mission is to provide innovative, efficient,and high-quality solutions for vape oil filling, capping, packaging, and related services.

Our core values—Efficiency and Precision, Saving you More. This is the heart of everything we do. Both our sales team and R&D experts prioritize these principles, driving us to empower businesses to thrive in an everevolving, competitive market.

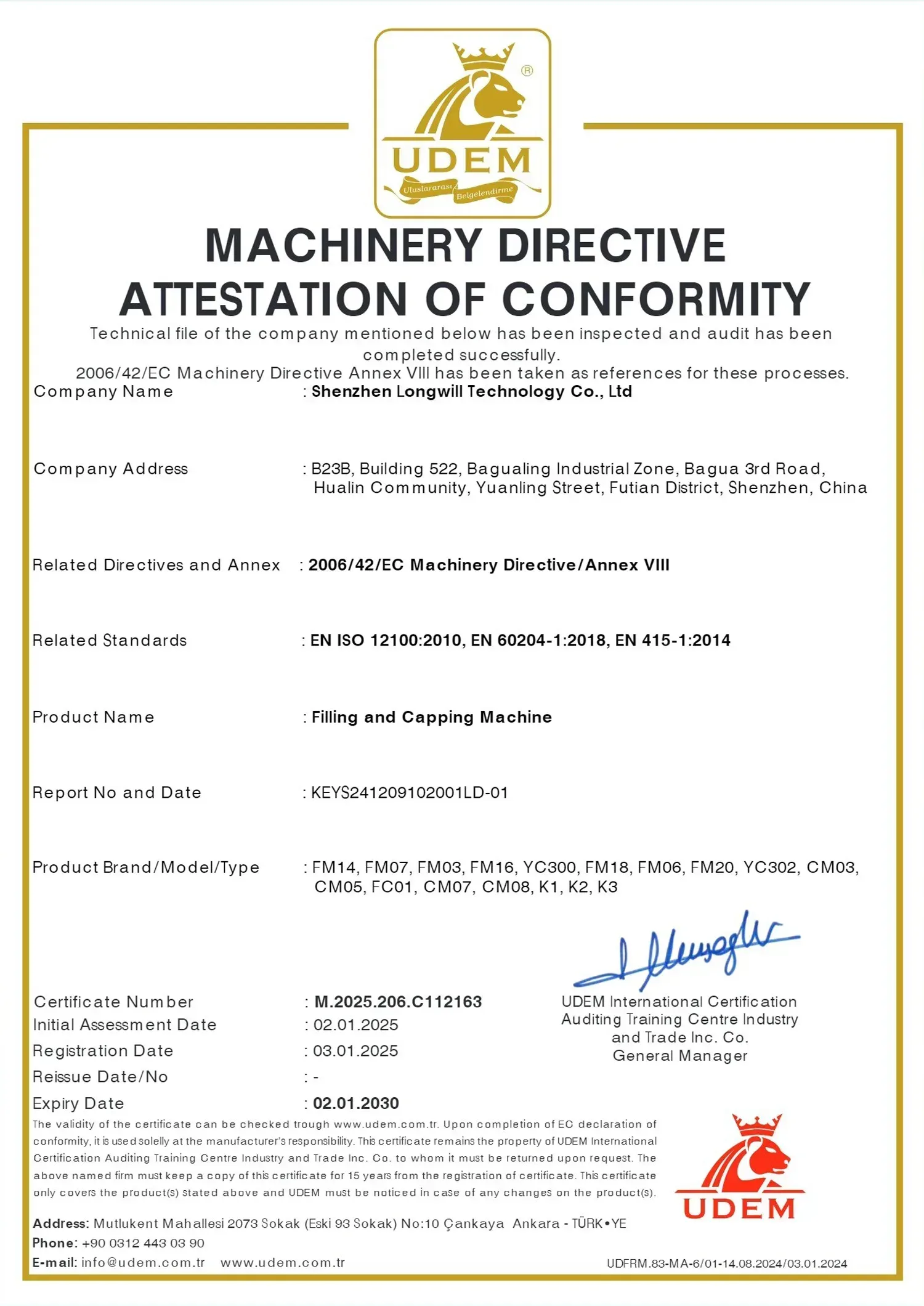

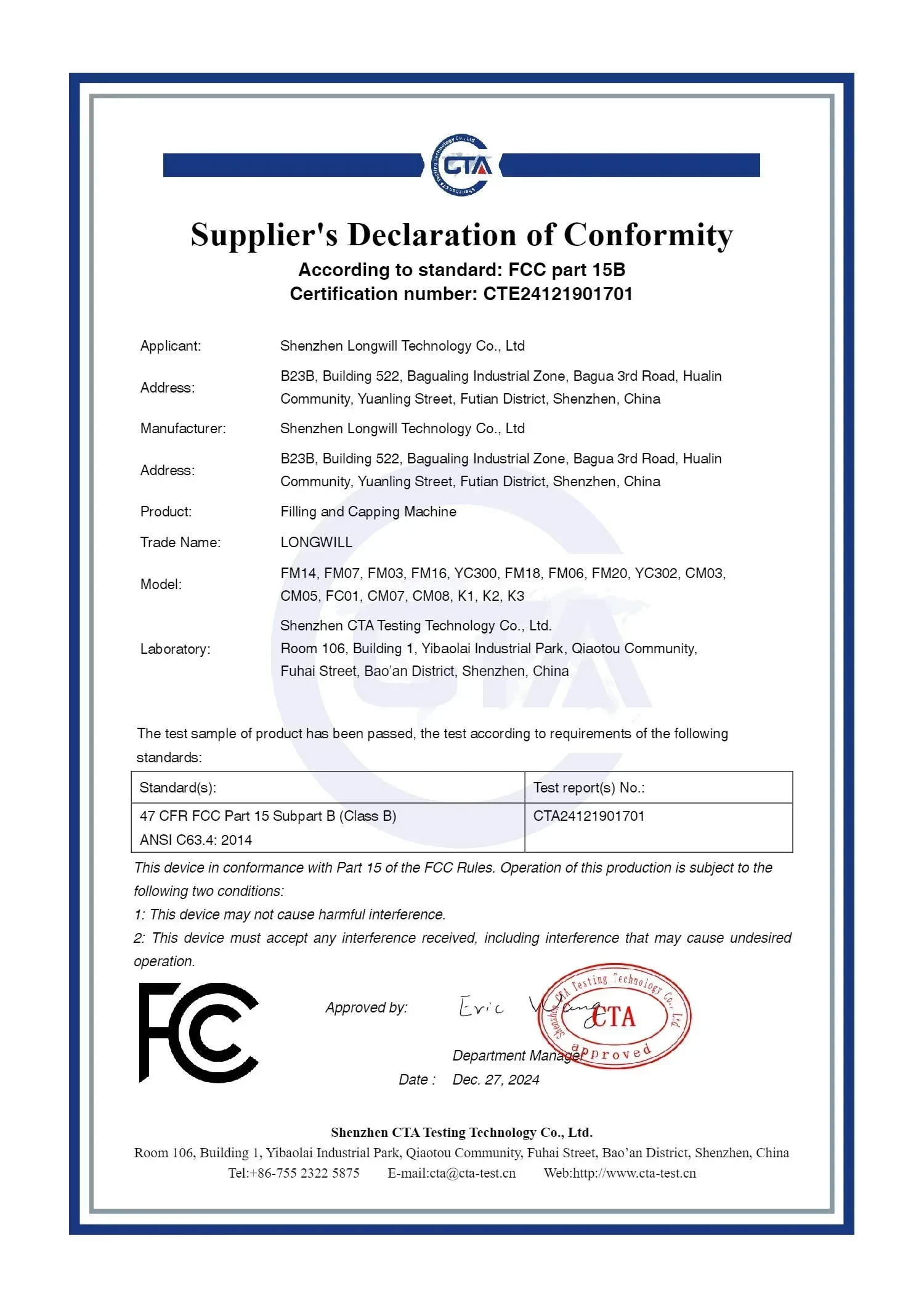

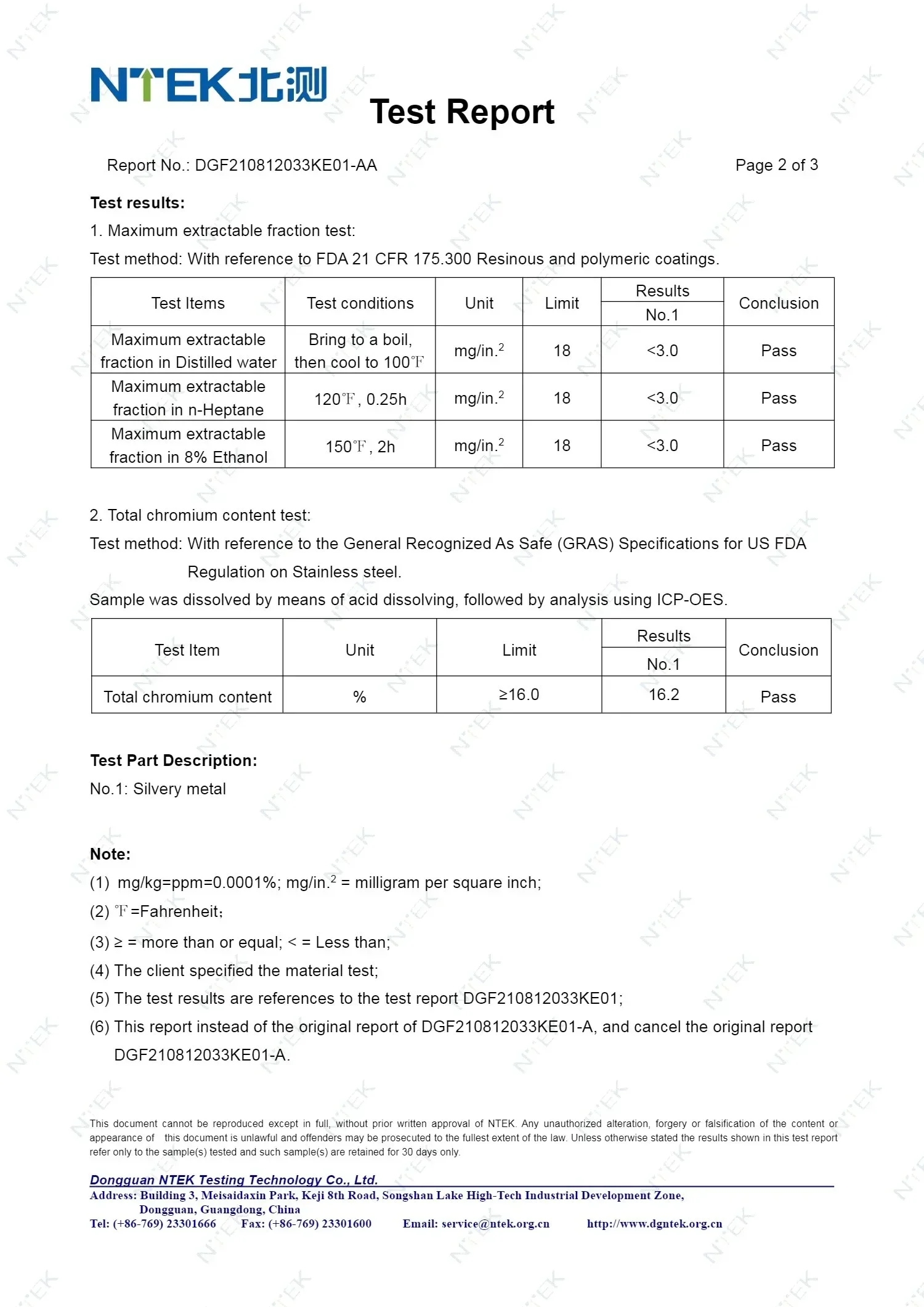

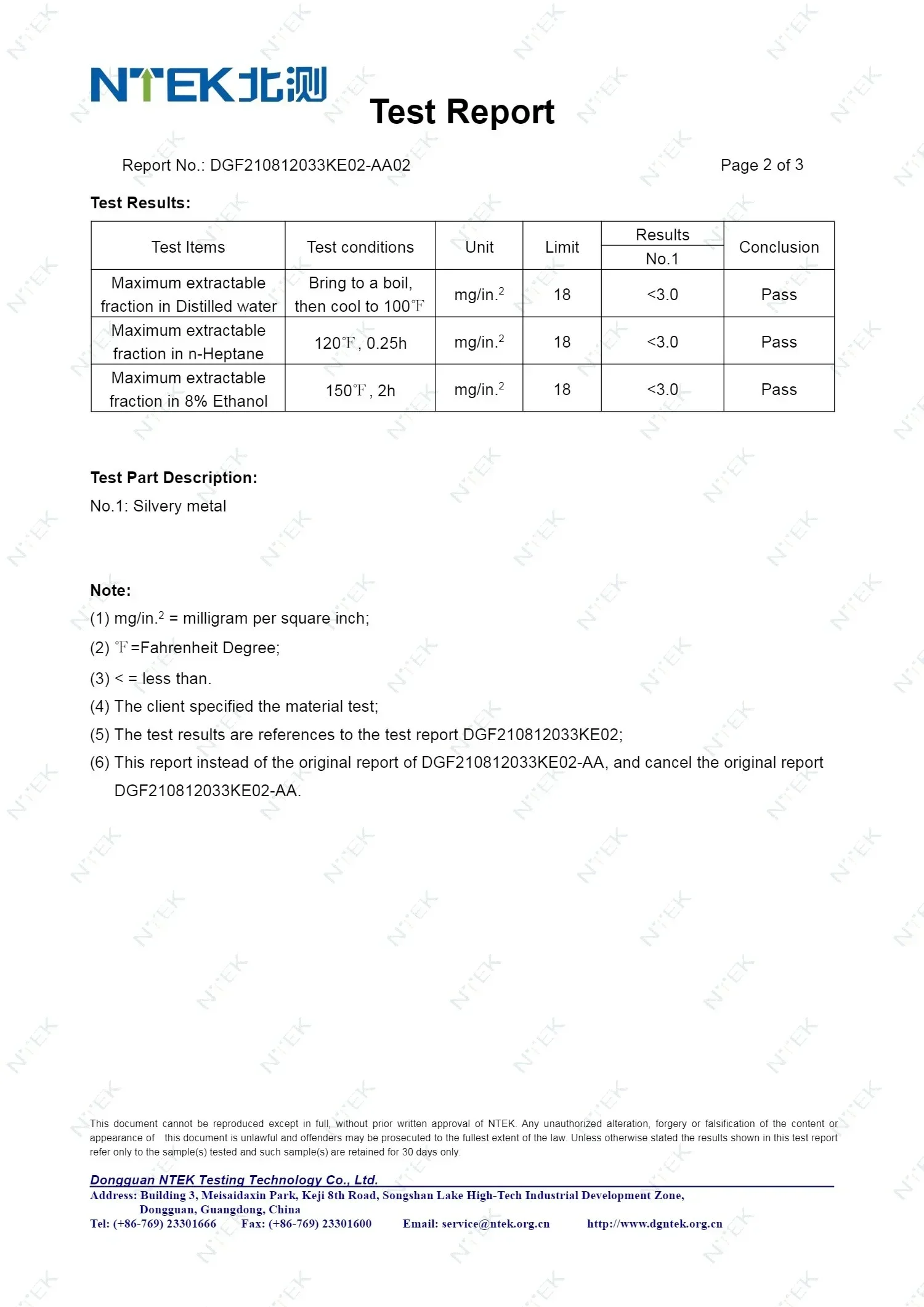

Contact UsCertifications and Honors

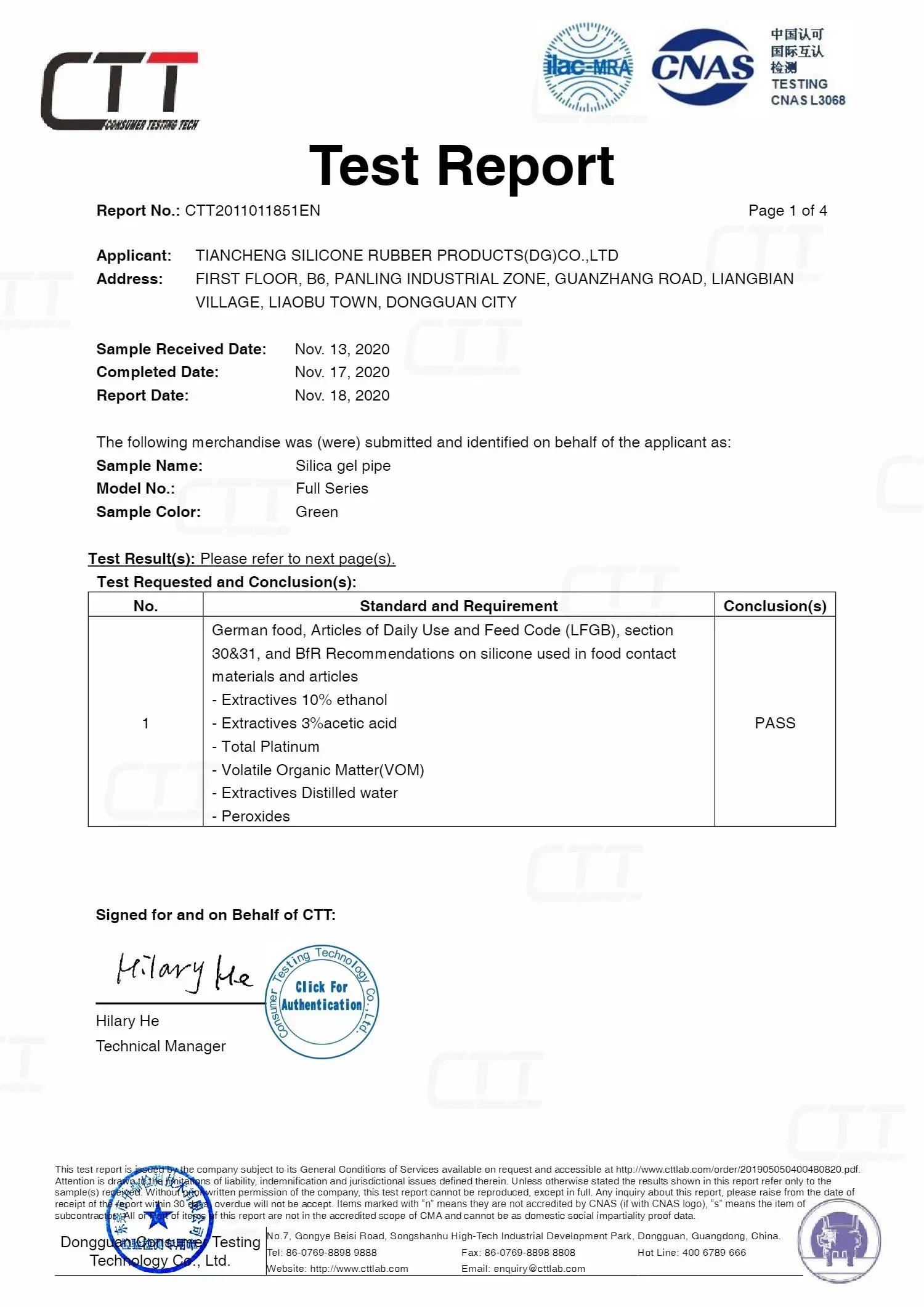

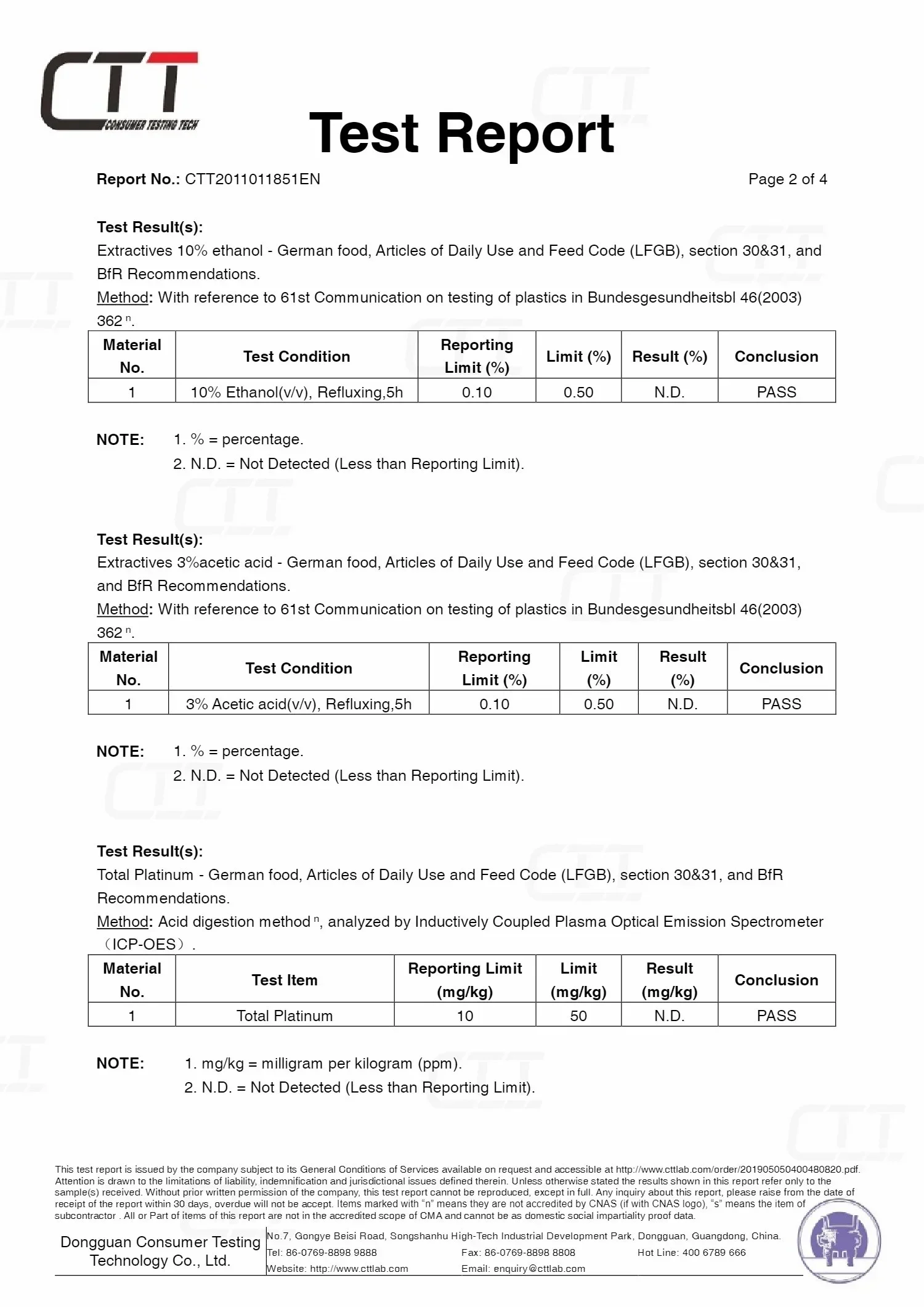

All machines have passed CE and FCC certifications, allowing them to be sold in most countries

worldwide. Additionally, the silicone tubing has passed the LFGB

test in Germany, the pumps and

oil barrels have passed the FDA test in the United States, and all materials in contact with the oil are

safe.

Successful Cooperations

Feedback from Customers

Riley Quinn

— Production Manager

"The filling machine we purchased has drastically im-

proved our production efficiency. Its speed and precision are unmatched, saving us both time and material costs. Coupled with fast delivery and excellent after-sales service, your team has been a true partner in our success!"

James Harrison

— Operations Director

"Your capping machine has been a game-changer for our operations. The reliability and accuracy of the equipment ensure every product meets our high-quality standards. The cost savings and seamless integration into our workflow make it one of the best investments we've ever made."

Victoria Clarke

— Plant Manager

"From the moment we placed the order, the entire process was smooth and efficient. The filling and capping machines were delivered quickly, and they exceeded our expectations in terms of speed, reliability, and ease of use. Your after-sales team was incredibly supportive—highly recommended!"

Let's Build Your Product

Unlock the Full Potential of Your Product Development Partner with our expert team at Longwill Equipment to bring your ideas to life. Fill out the form below, and let's take the first step together in turning your vision into reality.

How Does a Pre-Roll Infusion Machine Work

2026-01-15

In the rapidly growing cannabis industry, consistency, quality, and efficiency are key to success. Pre-roll infusion machines have become a vital tool for producers looking to scale their operations and create high-quality infused pre-rolls with precision. These machines automate the process of injecting cannabis concentrates into pre-filled joints, ensuring an even burn, consistent potency, and a smoother smoking experience. From distillates to live resin, pre-roll infusion machines like the Longwill 10 Nozzle Pre-Roll Infusion Machine offer a reliable, scalable solution for manufacturers aiming to meet the increasing demand for infused products. This article is designed to walk you through how pre-roll infusion machines work, the different types of concentrates used in the process, and the benefits of automation over manual infusion methods. What Is a Pre-Roll Infusion Machine?A pre-roll infusion machine is an automated device designed to precisely inject cannabis concentrates into pre-filled joints or cones. Instead of coating the outside of the pre-roll, the machine places a controlled amount of concentrate—such as distillate, live resin, or live rosin—directly into the center of a joint that has already been filled with ground flower. This internal infusion method ensures greater accuracy in both dosage and placement, with the added benefit of repeatability. Unlike traditional manual methods, which rely on hand application and visual judgment, a infused pre roll machine uses advanced temperature control, precision injection systems, and programmable settings to achieve consistent results. The machine produces a center-infused pre-roll that burns evenly, creating the distinctive "hash hole" or "donut joint" effect. As the flower burns, the concentrate vaporizes smoothly, preserving airflow and enhancing the overall smoking experience. With its high level of precision and scalability, this machine is ideally suited for commercial cannabis production, offering a level of consistency that manual processes simply can't match. How Does a Infused Pre Roll Machine Work?A pre-roll infusion machine is designed to automate the entire infusion process, ensuring precision and consistency at every step. The process begins by loading pre-filled joints, already packed with ground flower, into the machine’s specialized tray. Once in place, the system takes over, automatically dispensing and injecting the perfect amount of cannabis concentrate into the center of each pre-roll. Throughout the process, the machine carefully controls temperature and flow, guaranteeing an even and smooth distribution of concentrate. With advanced features like automated dosing, temperature regulation, and machine vision for precise placement, the system minimizes human error and variability. This results in a consistently high-quality infused pre-roll that meets exact potency and quality standards. By reducing the need for manual labor and maximizing automation, the machine ensures a scalable, repeatable production process, making it ideal for large-scale cannabis manufacturing where uniformity and efficiency are key. The Preroll Infusion Machine Process with the Longwill (Step-by-Step)1. Preparation: Loading Pre-Filled JointsThe process begins by placing pre-filled joints, packed with finely ground cannabis flower, into the specialized tray of the Longwill 10 Nozzle Pre-Roll Infusion Machine. This tray ensures each pre-roll is properly aligned, allowing for smooth handling and precise infusion as the system takes over. 2. Heating and Flow ControlEquipped with advanced temperature control, the machine features multiple heating zones to maintain the optimal viscosity of the cannabis concentrate. Whether using distillates, live resin, or terpene-infused oils, the Longwill preroll infusion machine system ensures a smooth, consistent flow, preventing clogs or inconsistencies and guaranteeing even distribution of concentrate throughout each pre-roll. 3. Precision InjectionThe Longwill machine uses 10 independent nozzles to inject a precise amount of cannabis concentrate directly into the center of each pre-roll. This multi-nozzle system enhances efficiency by infusing multiple pre-rolls at once, while maintaining consistency in concentrate placement and ensuring each pre-roll has a uniform potency. 4. Dosing and PlacementWith programmable settings, the machine allows operators to easily adjust the infusion volume (from 0.1 ml to 3 ml) and specify the exact placement of concentrate within the pre-roll. This flexibility ensures precise control over dosage, resulting in consistently high-quality infused pre-rolls that meet the desired standards across large production batches. 5. Final Product OutputAfter infusion, the pre-rolls are ready for packaging. The Longwill 10 Nozzle Pre-Roll Infusion Machine guarantees each infused pre-roll meets rigorous quality standards, delivering consistent results with minimal manual intervention. Perfect for high-volume, commercial cannabis production, this preroll infusion machine offers unmatched scalability, ensuring efficient, uniform output every time. Manual vs Automated Infused Pre-roll MachineAspectManual InfusionAutomated Infused Pre-roll MachinePrecision and ConsistencyInconsistent dosing and placementHigh precision with consistent dosage and placementLabor IntensityHigh labor requirement, requires skilled laborLow labor requirement, minimal manual interventionEfficiencyTime-consuming, slower production ratesFaster and scalable production with higher throughputCompliance and Quality ControlDifficult to maintain quality control across batchesEnsures consistent quality and complies with regulationsCost EfficiencyHigher operational costs due to manual labor and wasteLower operational costs with reduced waste and laborScalabilityLimited scalability, hard to increase production volumeScalable for high-volume, commercial production Types of Concentrates Used in Pre-Roll Infusion Machine1.DistillateA highly refined cannabis extract known for its potent effects and versatility. Distillates are favored for their clarity, potency, and lack of residual plant material, making them a reliable choice for infusions. 2.Live ResinExtracted from freshly harvested and flash-frozen cannabis, live resin preserves a rich terpene profile, delivering a flavorful and aromatic experience when infused into pre-rolls. 3.Live RosinA solvent-free concentrate made by applying heat and pressure to fresh or frozen flower. It’s prized for its purity, capturing the full spectrum of cannabinoids and terpenes for a high-quality flavor. 4.Viscosity and Temperature ConsiderationsEach concentrate has specific viscosity and temperature needs for optimal infusion. Maintaining the right temperature and consistency is essential to ensure smooth flow and prevent clogs during the infusion process. ConclusionThe pre-roll infusion machine is revolutionizing the way cannabis products are manufactured, offering significant advantages in precision, efficiency, and scalability. By automating the infusion process, manufacturers can reduce labor costs, eliminate variability, and consistently produce high-quality pre-rolls that meet regulatory standards.

Dab Filling Machine Safety: The Complete Process

2025-12-26

This guide details each essential phase of operating a dab filling machine, from setup to daily maintenance. It provides operators with a clear, actionable framework to perform tasks safely and efficiently, helping to prevent common errors and ensure consistent, high-quality filling results. Dab Machine Setup: Preparing Materials and Workspace1. Material Readiness & Pre-Filling ProtocolAchieving Uniform ConsistencyA critical first step in operating your dab machine is to ensure your concentrate is perfectly homogeneous. Vigorously stir or mix the material to eliminate all air pockets and achieve a smooth, even texture. Trapped bubbles will disrupt the machine's metering accuracy, leading to under-filled or inconsistent products that fail to meet quality standards. Temperature ConditioningFor the dab filling machine to function efficiently, the concentrate often needs to be brought to an ideal working temperature before loading. Pre-warming the material to its target range (commonly 40-60°C) lowers its viscosity. This conditioning step reduces strain on the machine's mechanisms and promotes a steady, reliable material flow from the first unit to the last. Preparing ContainersEvery container destined for filling—jars, cartridges, or pods—must be prepared to a high standard of cleanliness. They should be meticulously washed, fully dried, and inspected to be free of any particulate matter. Impurities can compromise the end product's purity and are a common cause of clogging in the machine's precision dispensing tips. 2. Configuring the WorkspaceEnsuring Adequate AirflowMaintaining proper ventilation is a fundamental safety measure for any filling station. The work area must be designed with enough air exchange or targeted extraction to handle any subtle vapors generated as concentrates are heated during the machine's operation. This safeguards air quality and ensures a healthier atmosphere for personnel. Stabilizing Ambient ConditionsConsistent filling results depend on a controlled workspace environment. Aim to keep the room temperature stable, ideally within 20-25°C, and manage humidity levels. Avoiding high-moisture conditions is important to protect the electrical systems of your equipment and to prevent moisture-sensitive concentrates from altering their properties. Maintaining a Controlled ZoneDedicating a specific area as a clean zone for your dab making machine is key to minimizing external contamination. Restrict non-essential activity in this space to limit airborne dust. Surfaces should be kept clean and be made of non-porous, easy-to-sanitize materials to uphold a controlled and professional operation. Dab Making Machine Setup and Calibration: The Foundation of Safe Operation1. Initial Dab Making Machine Safety VerificationVerifying Electrical IntegrityPrior to activating your machine dab, conduct a complete check of its electrical system. Confirm the power source is reliable, inspect all wiring for integrity, and verify that the unit is correctly grounded. This routine is essential for preventing potential electrical faults during operation. Assessing Mechanical ComponentsCarefully examine all mechanical elements, including pneumatic actuators and slide rails, to ensure they move freely without binding. Be alert for any atypical sounds that could signal mechanical issues, and remove any items that might interfere with the machine’s normal motion path. Temperature System CalibrationAccurate temperature calibration is fundamental for reliable performance. Using a certified reference thermometer, compare the actual temperatures at key points—the material hopper, delivery lines, and dispensing nozzle—against the machine's control panel readings. Consistent calibration maintains process accuracy and safeguards product quality. 2. Process Parameter Setup and ValidationEstablishing Temperature ProfilesConfigure the independent temperature zones of your machine dab to match the thermal requirements of your specific concentrate. Initiating heat at the lower spectrum of the recommended window and slowly ramping up helps avoid sudden thermal stress on the material, which can preserve its properties and prevent unwanted bubbling or degradation. Calibrating for Precise DosingEnter the desired fill weight into the machine’s interface. To validate accuracy, execute several test cycles, collecting and weighing the dispensed material on a precision scale. Iteratively adjust the settings until the results reliably meet your specified weight tolerance (e.g., ±1%). This diligent calibration is critical for ensuring consistent portioning. Optimizing Motion and Flow SettingsTailor the machine's operational dynamics—such as the nozzle travel speed and the rate of material discharge—to the viscosity of your concentrate and the design of your container. Well-adjusted motion profiles are key to achieving neat, complete fills without issues like splatter, webbing, or uneven distribution, streamlining your production process. Standardized Operating Procedure for Weed Wax Machines1.Loading the ConcentrateCarefully transfer your pre-conditioned material into the hopper of the weed wax machine using a steady, controlled pouring technique. This helps minimize turbulence and prevents air bubbles from being introduced—both critical for ensuring accurate dosing and a consistent end product. Once loaded, promptly secure the hopper lid to maintain optimal temperature and protect the material from external contaminants. 2.Filling Cycle OperationsBefore starting a full production batch, always perform a first-article verification. Run the dab filling machine to produce 3–5 test units, then immediately weigh and visually inspect them. This confirms that fill weight meets the target specification and that the output is free of defects, validating that all system parameters are set correctly. During the filling run, carry out consistent quality checks. Sample units periodically—for example, every 30 minutes—to verify fill weight and check for issues such as bubbles or incomplete fills. At the same time, continuously monitor the temperature readings across all heating zones. Any significant or sustained deviation should prompt an immediate pause to identify and address the cause. If a nozzle clog or inconsistent filling occurs, stop the machine right away. Clear blockages using the appropriate pre-warmed cleaning tools designed for the equipment. Never attempt to clear a clog by hand while the machine is running or when components are still hot. 3.Mandatory System CleaningOnce a batch is finished or when switching between different concentrate types, perform a complete and immediate system clean-out. This step is essential to prevent cross-contamination between product batches, ensuring each product maintains its intended purity and flavor integrity. Dab Filling Machine Maintenance: Cleaning, Upkeep, and Safety Readiness1. Daily Cleaning ProtocolMaintaining a consistent daily cleaning routine is vital for your dab machine’s performance and product integrity. Begin by flushing the hopper, supply lines, and dispensing nozzle with a food-grade solvent like ethanol while the unit is still warm, allowing residual concentrate to dissolve easily. For persistent buildup, periodically disassemble components such as nozzles and seals for ultrasonic cleaning. After cleaning, ensure all parts and internal passages are fully dry before reassembly to prevent operational issues in subsequent production cycles. 2. Preventive Maintenance ScheduleAdhering to a regular maintenance schedule helps extend the lifespan of your filling equipment and ensures consistent output. This includes routinely inspecting and tightening mechanical fasteners and electrical connections that can loosen over time. Follow a usage-based plan to replace wear items—such as seals, diaphragms, and tubing—before they compromise performance. Keeping a detailed maintenance log supports equipment tracking, aids in scheduling future service, and assists with quality assurance documentation. 3. Emergency Preparedness PlanPreparedness is key to managing unexpected situations safely and efficiently. Confirm that all operators know where the emergency stop controls are located and understand how to use them, testing these functions periodically. Ensure that appropriate safety equipment—including a first-aid kit and a properly rated fire extinguisher—is kept accessible near the work area, and that staff are trained in its use. Establish and periodically review straightforward response protocols for common minor incidents, such as small concentrate spills or minor thermal contact, to enable quick and calm resolution without escalation. Read more:https://longwillmachinery.com/Blog/semi-automatic-vs-fully-automatic-dab-machines-filling-machine-comparison-for-wax-oil.htmlhttps://longwillmachinery.com/Blog/how-does-a-dab-filling-machine-work.html ConclusionMastering the operational techniques of your filling equipment is just the beginning. Internalizing safety and standardization into daily practice is the cornerstone of achieving long-term, reliable performance and commercial success.

Semi-Automatic vs Fully Automatic Dab Machines: Filling Machine Comparison for Wax & Oil

2025-12-23

In this guide, we’ll compare semi-auto vs full-auto dab machines side by side and break down the key factors that matter most for real-world wax and oil filling. Semi-Automatic vs Fully Automatic Dab Machines: Quick Comparison TableItemVape-Jet Dab Dispenser (Semi-Automatic)Longwill Dab Wax Filling Machine (Fully Automatic)Machine typeSemi-automatic jar filling + weight checkFully automatic dab wax filling machinePrimary useConcentrate jar filling (e.g., 1g jars)Dab/wax filling; supports jars and other formats (with fixtures)Throughput (claimed)Up to 500 x 1g jars/hour2000–3000 sticks/hour (site also lists 20–30 pcs/min)Accuracy (claimed)±1% (with automated weight check)±0.01 ml (site also lists 0.01g)Reservoir / tank1L removable stainless reservoir1L oil tankHeating / viscosity approach“No-to-low heat” + nitrogen-pressurized dispensingHeated system, temperature range 0–120°CControl styleSemi-auto operation; integrated scale + auto-calibrationTouchscreen + PLC; motor/ball-screw controlBest fitBrands prioritizing jar filling + weight validationBrands needing fully automatic precision + higher productivity What Are Semi-Automatic Weed Wax Machines?A semi-automatic dab filling machine is a solid upgrade from hand filling, improving consistency and efficiency while still keeping the operator involved. In most setups, the operator loads and removes containers, starts each cycle, and may verify or fine-tune the fill by volume or weight. Put simply, the dab machine handles controlled dispensing (often with heating), while the operator controls the pace and handling. Semi-auto systems are often chosen for their flexibility. They’re well suited for smaller runs, frequent SKU changes, and jar-filling workflows where quick visual checks and hands-on adjustments are part of daily production. Since the system is typically less complex than a fully automated line, it’s also easier to maintain, easier to troubleshoot, and more budget-friendly. For many teams, a semi-automatic weed wax machine is the practical next step—ideal for moving beyond syringes, supporting in-house dab wax filling, and increasing output without jumping straight into full automation. What Are Fully Automatic Dab Filling Machines?A fully automatic weed wax machine runs the filling process as a programmed sequence, so day-to-day production requires far less hands-on work. In a typical workflow, the operator sets key parameters—fill volume, temperature, speed, and positioning—loads the tray/jig (or fixtures), and starts the cycle. After that, the dab machine handles the rest: it moves into position, dispenses the preset amount, and repeats the same routine across the batch. Many systems add multi-nozzle filling to increase throughput while keeping results consistent from unit to unit. What makes it “fully automatic” is the combination of control and stability behind the scenes. Most machines use PLC + touchscreen control to run repeatable cycles, precision motion components (rails and lead screws driven by a servo or stepper motor) to maintain accurate positioning, and a metered pump system to deliver consistent dosing. For thick wax and high-viscosity oils, temperature-controlled material paths are often included to keep flow steady and help reduce clogging, tailing, or slowdowns during longer runs. Overall, a fully automatic dab filling machine is a strong fit for growing brands that need higher precision, higher output, less dependence on operator technique, and more consistent results across shifts. Key Comparison Points for Wax & OilWhen you’re filling wax, rosin, and other thick oils, the “best” option usually comes down to how well the system manages viscosity, stays stable over long runs, and delivers a clean cut-off. Below are the factors that matter most in day-to-day production—whether you’re using a semi-auto setup or a fully automatic wax weed machine. 1) Viscosity Handling and Temperature ControlA semi-automatic dab machine can handle thick material well—especially if you like hands-on control—but results may vary more with operator pace and technique. Heating is sometimes simpler, such as primarily warming the reservoir. A fully automatic dab filling machine typically holds steadier output because it runs at a consistent rhythm and maintains controlled conditions. Multi-zone heating (tank + line/nozzle) is especially useful for preventing cooling, clogging, and tailing when viscosity shifts during a run. 2) Fill Consistency: Volume vs. WeightSemi-auto workflows often involve more operator checks and may lean on weight verification, which can be ideal for jar filling where weight is the main QC point—though it can slow throughput. Fully automatic wax weed machines usually focus on repeatable dosing cycle-to-cycle; with stable positioning and metered dispensing, they tend to deliver tighter unit-to-unit consistency across larger batches. If you’re scaling, the key is consistency not only at startup, but also after pauses, refills, and longer runs. 3) Throughput and Labor EfficiencyA semi-automatic dab machine is generally much faster than hand filling, but output is still tied to people—starting cycles, handling containers, and keeping the pace moving. A fully automatic weed wax machine is designed to raise throughput without increasing labor at the same rate; once loaded and started, it can run steady batch cycles with less operator involvement. If labor is your biggest bottleneck, full automation is often the clearest path to more capacity. 4) Clean Cut-Off, Drips, and “Tailing”Thick concentrates tend to string, so clean cut-off becomes a major differentiator. Nozzle diameter, heat stability near the tip, pump start/stop control, and repeatable motion all influence whether you get clean breaks or messy tails. Semi-auto can still be clean, but it’s more dependent on operator timing. Fully automatic systems typically synchronize motion and dispensing the same way every cycle, which helps reduce drip variation and keeps results more uniform across the tray. 5) Changeovers, Cleaning, and Multi-SKU WorkflowsSemi-auto weed wax machines can be quicker to clean simply because the systems are often simpler and operators are already working hands-on. Fully automatic machines can also clean up fast when they’re designed with a short oil path, removable contact parts, and easy access to the reservoir and lines. Where full automation often wins is changeover consistency—saved programs and repeatable positioning make switching SKUs more predictable. No matter which route you choose, prioritize easy disassembly, low dead volume, and quick-change nozzles/fixtures if you run multiple products. 6) Flexibility: Hardware and Container CompatibilitySemi-automatic setups feel flexible because operators can adapt quickly to different jars or formats. A fully automatic dab machine can be just as flexible when the platform supports interchangeable trays/jigs, nozzle options, and simple parameter adjustments. If you fill a mix of carts, pods, pens, and jars, look for a system built around fixture swaps and adjustable positioning—not one locked into a single format. 7) Cost of Ownership and Scaling PathSemi-automatic machines typically have a lower entry cost and straightforward maintenance, making them a solid upgrade from manual processes. Fully automatic systems cost more upfront, but they often reduce cost per unit at scale through higher throughput, steadier output, and less labor dependence. If you expect growth in the next 6–18 months, a fully automatic dab filling machine can become the more economical choice once labor savings and production stability start to compound. Read more:https://longwillmachinery.com/Blog/how-does-a-dab-filling-machine-work.htmlhttps://longwillmachinery.com/Blog/how-to-choose-a-dab-filling-machine-for-solventless-concentrates.html ConclusionThere isn’t a one-size-fits-all answer—your best choice depends on your product type, batch size, staffing, and growth plan. A semi-automatic dab machine is often the practical step up from manual filling when you want flexibility and hands-on control, especially for smaller runs or frequent changeovers. A fully automatic dab filling machine is typically the better fit when you need higher output, tighter repeatability across shifts, and less reliance on operator technique.