How Does a Pre-Roll Infusion Machine Work

In the rapidly growing cannabis industry, consistency, quality, and efficiency are key to success. Pre-roll infusion machines have become a vital tool for producers looking to scale their operations and create high-quality infused pre-rolls with precision. These machines automate the process of injecting cannabis concentrates into pre-filled joints, ensuring an even burn, consistent potency, and a smoother smoking experience. From distillates to live resin, pre-roll infusion machines like the Longwill 10 Nozzle Pre-Roll Infusion Machine offer a reliable, scalable solution for manufacturers aiming to meet the increasing demand for infused products.

This article is designed to walk you through how pre-roll infusion machines work, the different types of concentrates used in the process, and the benefits of automation over manual infusion methods.

What Is a Pre-Roll Infusion Machine?

A pre-roll infusion machine is an automated device designed to precisely inject cannabis concentrates into pre-filled joints or cones. Instead of coating the outside of the pre-roll, the machine places a controlled amount of concentrate—such as distillate, live resin, or live rosin—directly into the center of a joint that has already been filled with ground flower. This internal infusion method ensures greater accuracy in both dosage and placement, with the added benefit of repeatability.

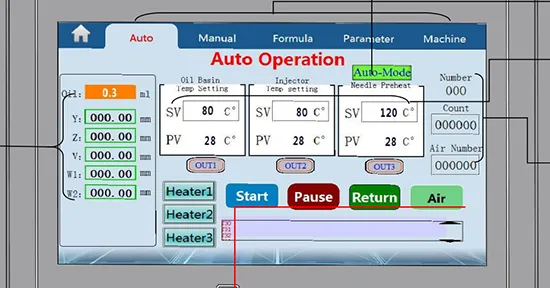

Unlike traditional manual methods, which rely on hand application and visual judgment, a infused pre roll machine uses advanced temperature control, precision injection systems, and programmable settings to achieve consistent results. The machine produces a center-infused pre-roll that burns evenly, creating the distinctive "hash hole" or "donut joint" effect. As the flower burns, the concentrate vaporizes smoothly, preserving airflow and enhancing the overall smoking experience. With its high level of precision and scalability, this machine is ideally suited for commercial cannabis production, offering a level of consistency that manual processes simply can't match.

How Does a Infused Pre Roll Machine Work?

A pre-roll infusion machine is designed to automate the entire infusion process, ensuring precision and consistency at every step. The process begins by loading pre-filled joints, already packed with ground flower, into the machine’s specialized tray. Once in place, the system takes over, automatically dispensing and injecting the perfect amount of cannabis concentrate into the center of each pre-roll. Throughout the process, the machine carefully controls temperature and flow, guaranteeing an even and smooth distribution of concentrate.

With advanced features like automated dosing, temperature regulation, and machine vision for precise placement, the system minimizes human error and variability. This results in a consistently high-quality infused pre-roll that meets exact potency and quality standards. By reducing the need for manual labor and maximizing automation, the machine ensures a scalable, repeatable production process, making it ideal for large-scale cannabis manufacturing where uniformity and efficiency are key.

The Preroll Infusion Machine Process with the Longwill (Step-by-Step)

1. Preparation: Loading Pre-Filled Joints

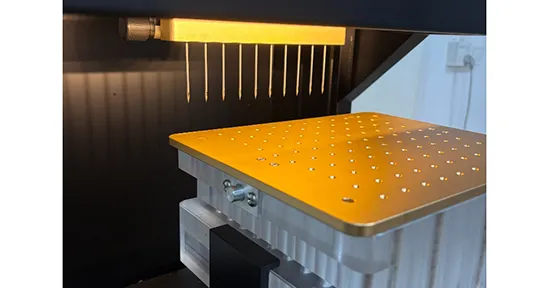

The process begins by placing pre-filled joints, packed with finely ground cannabis flower, into the specialized tray of the Longwill 10 Nozzle Pre-Roll Infusion Machine. This tray ensures each pre-roll is properly aligned, allowing for smooth handling and precise infusion as the system takes over.

2. Heating and Flow Control

Equipped with advanced temperature control, the machine features multiple heating zones to maintain the optimal viscosity of the cannabis concentrate. Whether using distillates, live resin, or terpene-infused oils, the Longwill preroll infusion machine system ensures a smooth, consistent flow, preventing clogs or inconsistencies and guaranteeing even distribution of concentrate throughout each pre-roll.

3. Precision Injection

The Longwill machine uses 10 independent nozzles to inject a precise amount of cannabis concentrate directly into the center of each pre-roll. This multi-nozzle system enhances efficiency by infusing multiple pre-rolls at once, while maintaining consistency in concentrate placement and ensuring each pre-roll has a uniform potency.

4. Dosing and Placement

With programmable settings, the machine allows operators to easily adjust the infusion volume (from 0.1 ml to 3 ml) and specify the exact placement of concentrate within the pre-roll. This flexibility ensures precise control over dosage, resulting in consistently high-quality infused pre-rolls that meet the desired standards across large production batches.

5. Final Product Output

After infusion, the pre-rolls are ready for packaging. The Longwill 10 Nozzle Pre-Roll Infusion Machine guarantees each infused pre-roll meets rigorous quality standards, delivering consistent results with minimal manual intervention. Perfect for high-volume, commercial cannabis production, this preroll infusion machine offers unmatched scalability, ensuring efficient, uniform output every time.

Manual vs Automated Infused Pre-roll Machine

Aspect | Manual Infusion | Automated Infused Pre-roll Machine |

Precision and Consistency | Inconsistent dosing and placement | High precision with consistent dosage and placement |

Labor Intensity | High labor requirement, requires skilled labor | Low labor requirement, minimal manual intervention |

Efficiency | Time-consuming, slower production rates | Faster and scalable production with higher throughput |

Compliance and Quality Control | Difficult to maintain quality control across batches | Ensures consistent quality and complies with regulations |

Cost Efficiency | Higher operational costs due to manual labor and waste | Lower operational costs with reduced waste and labor |

Scalability | Limited scalability, hard to increase production volume | Scalable for high-volume, commercial production |

Types of Concentrates Used in Pre-Roll Infusion Machine

1.Distillate

A highly refined cannabis extract known for its potent effects and versatility. Distillates are favored for their clarity, potency, and lack of residual plant material, making them a reliable choice for infusions.

2.Live Resin

Extracted from freshly harvested and flash-frozen cannabis, live resin preserves a rich terpene profile, delivering a flavorful and aromatic experience when infused into pre-rolls.

3.Live Rosin

A solvent-free concentrate made by applying heat and pressure to fresh or frozen flower. It’s prized for its purity, capturing the full spectrum of cannabinoids and terpenes for a high-quality flavor.

4.Viscosity and Temperature Considerations

Each concentrate has specific viscosity and temperature needs for optimal infusion. Maintaining the right temperature and consistency is essential to ensure smooth flow and prevent clogs during the infusion process.

Conclusion

The pre-roll infusion machine is revolutionizing the way cannabis products are manufactured, offering significant advantages in precision, efficiency, and scalability. By automating the infusion process, manufacturers can reduce labor costs, eliminate variability, and consistently produce high-quality pre-rolls that meet regulatory standards.