Your Ultimate Guide to Choose the Best Semi-Automatic Cartridge Filler for CBD Production

Introduction

The CBD industry is growing pretty fast, and therefore, precision and efficiency in product manufacturing are necessary to satisfy the rising demand for quality products. The cartridge-filling machine that one opts to buy contributes immensely to all factors of production for businesses running in an industry controlled by precision and efficiency. In this guide, we are going to get into the importance of choosing the perfect cartridge filling machine with relevance to the cartridge and Semi-automatic cartridge filler. This article focuses on providing a comprehensive review that will help one make an informed decision.

The Evolution of CBD Manufacturing

Years of consumer demand has led to an uptrend that is buoying explosive growth and diversification within the CBD industry. With rapid diversification comes the integral focus on manufacturing process precision and efficiency. Consistency and quality throughout the purchasing experience come as a hallmark of the competitive market.

Introduction of Cartridge Filling Machines

The cartridge filling machines come in various types, such as automatic and semi-automatic types.

Although these machines share some common features, they possess many important differences that are critical to understanding how and whether a given machine works efficiently. Choosing the right one for particular operational needs is clearly no trivial matter.

Automatic vs. Semi-automatic

With low labor requirements, automatic Cartridge filler machines are popular for high-volume production. Meanwhile, semi-automatic fillers combine manual control and automation to suit differing production scales.

Filling cartridges has important features necessary for their performance. These factors thus affect the efficiency and accuracy of filling. Choosing the right cartridge-filling machine is all part of operating efficiency. Each type is suited to different production scales and operating characteristics, stressing the importance of tailor-made choices.

Why Choose a Semi-automatic Cartridge Filler?

Semi-automatic vape cartridge filling machines are an attractive choice for many different industries. Knowing their advantages makes decision-making easy, especially for enterprises at medium-sized levels of production.

Semi-automatic cartridge fillers strike a balance of the middle way between filling machines, reconciling manual control with automated precision. However, unlike their entirely autonomous counterparts, these fillers require some intervention by an operator. They provide a flexible option for filling cartridges that suit a wide range of production scenarios.

Benefits of Semi-Automatic Fillers

●Cost-effective: Another great merit associated with the semi-automatic fillers is that they are cost-effective. All their efficiency is based on cost-saving purposes, making them an attractive option for those businesses running on a tight budget.

●Flexibility and Control: Semi-automatic fillers provide the prerequisite adjustable, controllable filling to be done with precision according to the precise product requirement of the operator. This user-controlled characteristic is a must to handle an assortment of cartridge types for all production needs.

●Perfect for Small to Mid-level Operations: Semi-automatic fillers are designed in mind for semi-large scale operation businesses, coming as a merger of efficiency and affordability so that they would be perfect for small companies.

Factors to Consider When Choosing a Semi-automatic Cartridge Filler

Usually, in selecting a semi-automatic Cartridge filler machine, there are a number of prime factors that should be taken into consideration so that its performance will properly meet the requirements of your own business.

A. Production Capacity

One shall establish an understanding of the required production scale. Semi-automatic fillers come with various production capacities. The most significant is to choose one that is appropriate for operational requirements.

B. Filling Accuracy and Precision

In the cartridge filler machine, the most critical function is certainly the dosing, which has to be pinpointed in nature. Semi-automatic alternatives necessitate filling accuracy and precision checks for maintaining and reproducibility of the product quality.

C. Fits any type of cartridges

Flexibility matters. Opt for semi-automatic filler that can accommodate different cartridge models to give a bit of flexibility in case there’s a change in production.

D. User-Friendliness and Ease of Operation

Ease of maintenance and user-friendliness will only result in many operational benefits. Therefore, pick up a machine that is not very complicated to handle and maintain that will enable you to cut down on valuable downtime.

E. Customization Options

Besides, different products may require other special filling arrangements. Identify semi-automatic fillers with possibilities of customization and fitting specific product needs.

F. Safety Features

Consider safety as a priority. The selected semi-automatic filler should have the basic safety features that will protect the operators as well as enhance production.

Common Mistakes to Avoid

As in purchasing a machine, it is important to understand some of the possible problems involved when buying vape cartridge filling machines.

Mistakes Businesses Make When Choosing a Cartridge Filler

Choosing CBD vape pen cartridge fillers requires attention yet businessmen often succumb to common oversights. Common errors include failing to consider the particular needs of certain operations, underestimating long-term costs, and not looking at safety features. Making decisions in a hurry, only based on immediate cost considerations, can easily result in choices that are not ideal for production efficiency and product quality.

Tips for Avoiding These Pitfalls

To avoid these risks, businesses must do thorough research. Analyze carefully the operating needs for such things as production capacity, material compatibilities, and long-run costs. Safety features should be emphasized to protect both the production process and personnel. By seeking advice from leading figures in the industry and learning from the lessons of others, you can gain a lot. In this way, companies can be adept in choosing a new Vape cartridge filling machine by taking meticulous and informed steps. By doing so, they’ll make an investment that will serve them well for years to come.

Comparison of Top Manufacturers Semi-Automatic Cartridge Fillers

In the realm of precision and efficiency, a thorough comparison of leading manufacturers of semi-automatic cartridge fillers is imperative. Explore the innovative and reliable machines by top cartridge filling machine Manufacturers.

- Longwill Machinery

Location: Shenzhen, China.

Years in Business: Since 2014.

Longwill specializes in manufacturing high-quality cartridge filling and capping machines, as well as 510 cartridges, and disposable pens and pods. The company is led by a chief engineer with over 20 years of experience and is committed to innovative and efficient solutions for the industry.

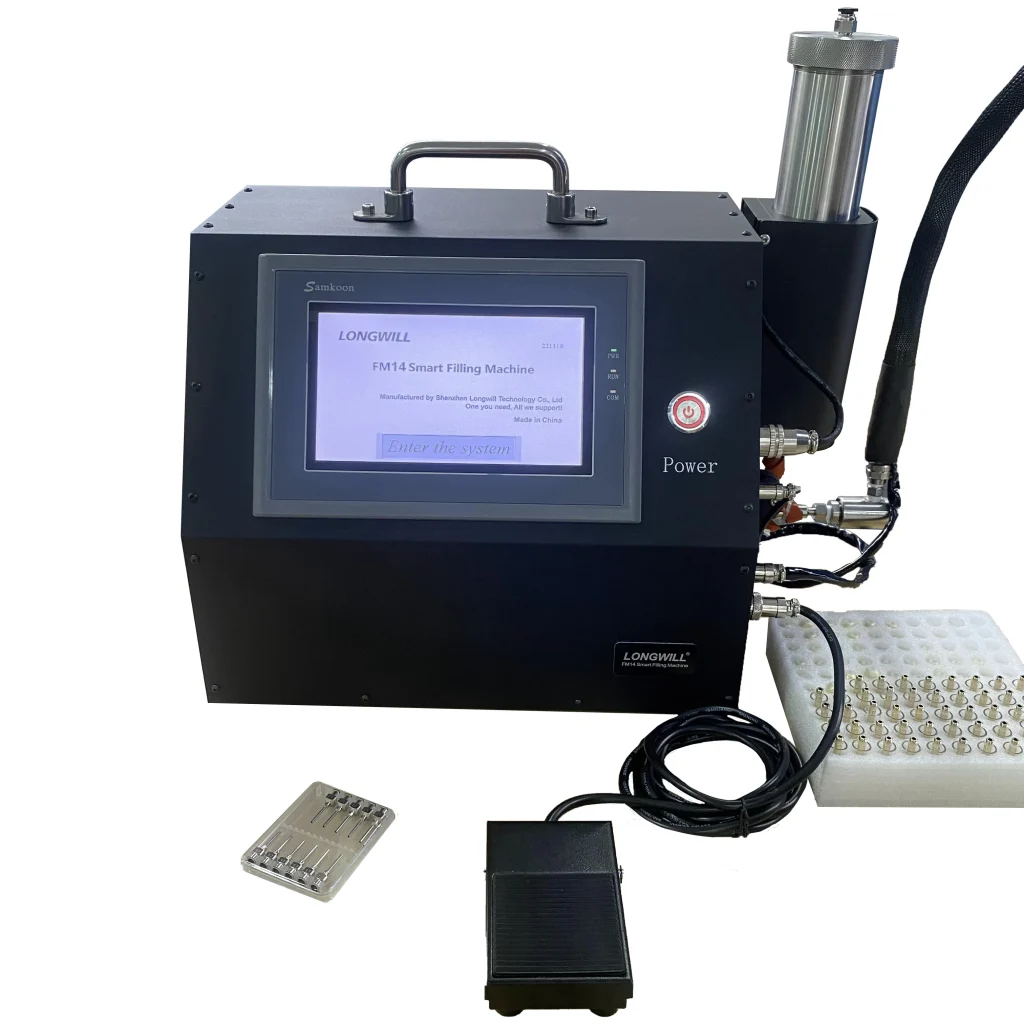

Product: FM14 Semi-Auto Vape Pen Filling Machine

LONGWILL has developed its Semi-Auto Cartridge Filling Machine with a Handheld Hose, which demonstrates the company’s spirit of invention. This machine finds a good balance between efficiency and user control so that it fills accurately every time. With critical control in the hands of operators, yet with automated processes it makes sure that each cartridge is a quality one. Its versatility extends throughout the different sizes of CBD vape pen cartridges, and it can be adjusted for whatever application is needed.

The fast changeover function makes switching out cartridges or volumes effortless, and downtime in CBD manufacturing is reduced to a minimum.

●Oiling Amount and Accuracy: Oil filling accuracy of ± 1 %, approximate amount ranging from 0.2-3ml/5 ml (about).

●Output: It claims productivity of 800-1500 sticks/hour, catering to different production needs.

●Versatility: Designed to accept many different CBD vape pen cartridges, with adjustable settings.

●Key Features: It includes a handheld hose to more easily fill precisely, thereby reducing the risks of spilling and maintaining product integrity. Furthermore, its user-friendly interface is easy enough for either experienced or novice operators to understand. It simplifies processes and reduces training needs.

User Reviews and Testimonials

Users say the FM14 Semi-Auto Vape Pen Filling Machine is strong, easy to use, changes out strains, and is clean. You can also add more products quickly. With large cartridge fillings, they’ve seen improved production and reliability over time.

- VapeJet

Location: Portland, Oregon, USA.

Years in Business: Founded in 2018.

Vape-Jet is known for its innovative semi-automatic and fully-automatic filling machines, including the Jet Fueler.

Product: Jet-Fueler Semi-Automatic Oil Cartridge Filling Machine

●Speed and Capacity: With a cutting-edge pharmaceutical-grade nitrogen-assisted pump that can fill 5000 to 9 thousand vape cartridges in shifts.

●Temperature Control: Using advanced temperature control, there are 3 separately programmable heat zones to maintain the quality of oil.

●Cleaning: Easy to clean in place, with full cleanup taking less than 10 minutes.

●Safety and Compliance: Granted CSA certification, conforming to North American safety standards.

- ATG Pharma

Location: North America.

Years in Business: Founded in 2003.

ATG Pharma began as an equipment validation and supply company and has evolved to produce high-quality filling and packaging equipment.

Product: ML-1VF

●Output Per Hour: 300 – 500

●Precision: Equipped with a volumetric filling nozzle capable of +/- 2 % dosing accuracy.

●Pressure Vessel: Designed for even flow and consistency, also to reduce waste and air bubbles.

●Capping Solution: It includes a capping solution that easily and safely closes cartridge caps within 45 seconds.

- CoolJarz

Location: Tustin, California, USA.

Years in Business: 9 years.

CoolJarz specializes in packaging machinery and provides innovative solutions like Cartridge Filling Machine, which emphasizes speed, efficiency, and nearly zero waste in cartridge filling.

Product: Hotshot™ 1500 Cartridge Filling Machine

●Speed and Efficiency: A unique semi-automatic design combining automation and manual control promises fast operation.

●Waste Reduction: Says it has almost no waste and low transportation costs for oil, eliminating unnecessary loss.

●Precision: Set specific amounts per shot, covering from 0.33 ml to 1 ml, and adjustable for different oil viscosities.

●Output: The 1-liter oil tank is capable of filling up to 12,000 cartridges in a single working day.

Recommendations

These semi-automatic cartridge fillers all have unique characteristics to satisfy different requirements.

You need to choose your semi-automatic cartridge filling machine carefully. Factors you must consider are the exact needs of your operation in terms of production capacity, oil type, and precision requirements, as well as budgetary constraints. You also need to consider user reviews and after-sale support, not merely investment over the short term.

Conclusion

To sum up, selecting the proper semi-automatic cartridge filler is a challenging decision that must be considered carefully. Recapitulate the key considerations and emphasize the importance of making informed decisions tailored to individual business needs. So, you readers should choose your cartridge-filling machine for quality, efficiency, and long-term benefits.

Remember, the success of your operations hinges on the precision and reliability of your cartridge filling machine. Invest smartly and push your business toward efficiency and profit.