Amount of oiling: 0.2-2ml

Oil tank: 300ml or 500ml or 3L

Oil filling accuracy: ±0.01ml

Output: 800-1200 sticks / hour

Power supply: AC220V/110V

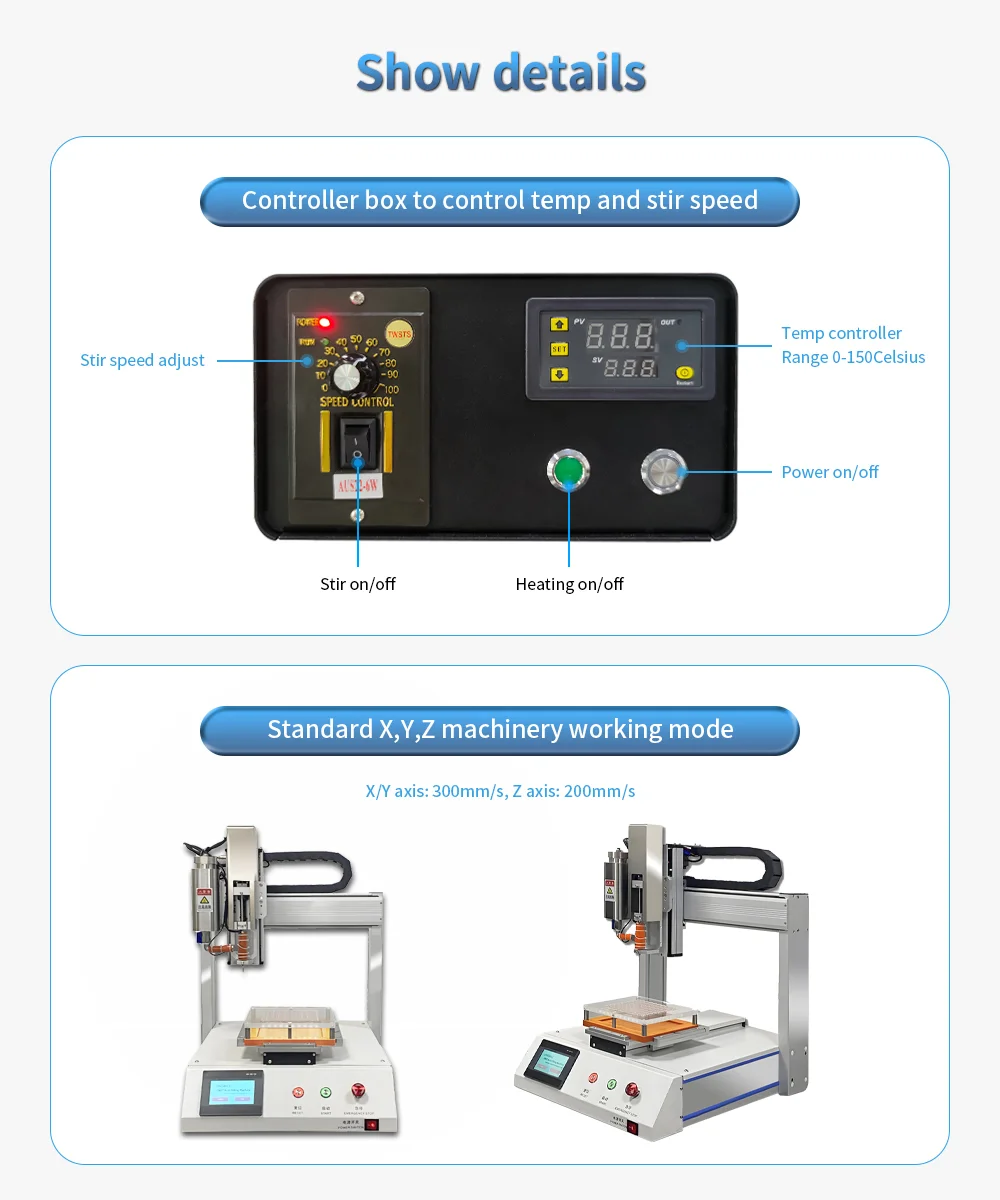

Drive mode: Stepper motor + rail drive

Temperature range: 0-120 celsius

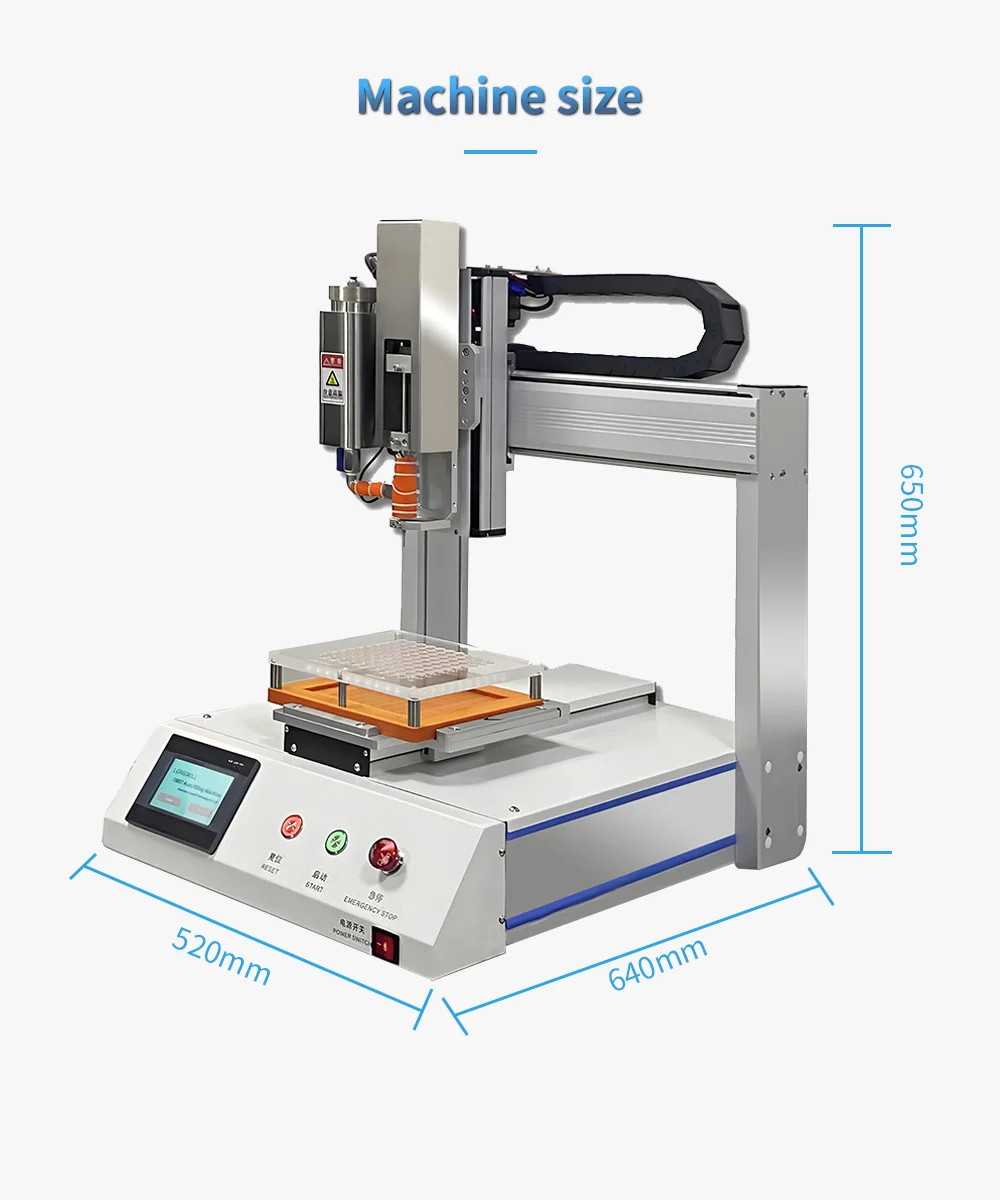

Export package size (mm) weight: Wooden box packaging *W*H=570*710*790mm,68kg without filling trays

Machine Dimensions W*D*H(mm) weight: 520*640*650mm,46kg

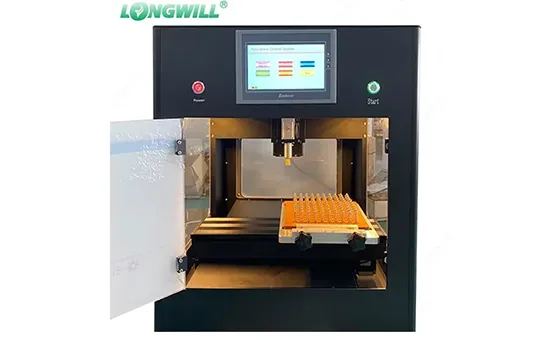

Panel control: Touch screen, operation button,emergency stop

Best Reviewed Thick oil High Precise 0.01ml increments Cartridge Filling Machine

| Model | FM-07 |

| Amount of oiling | 0.2-2ml, 0.2-5ml, 0.2-10ml |

| Oil filling accuracy | ±1% |

| Maximum speed | X/Y axis: 300mm/s, Z axis: 200mm/s |

| Output | 800-1200 sticks / hour |

| Drive mode | Stepper motor + rail drive |

| Panel control | Touch screen, operation button, emergency stop |

| Interface control | Position /fuel injection /speed adjustment, program selection |

| Control | PLC |

| Program capacity | Specifically based on PLC storage capacity |

| Power supply | AC220V/110V |

| Shipping | DHL/Fedex/ups, by air, by sea, by train door to door. |

| Payment | Support Kinds of payment, by Alibaba, Paypal, T/T, Western Union etc. |

Key Feature

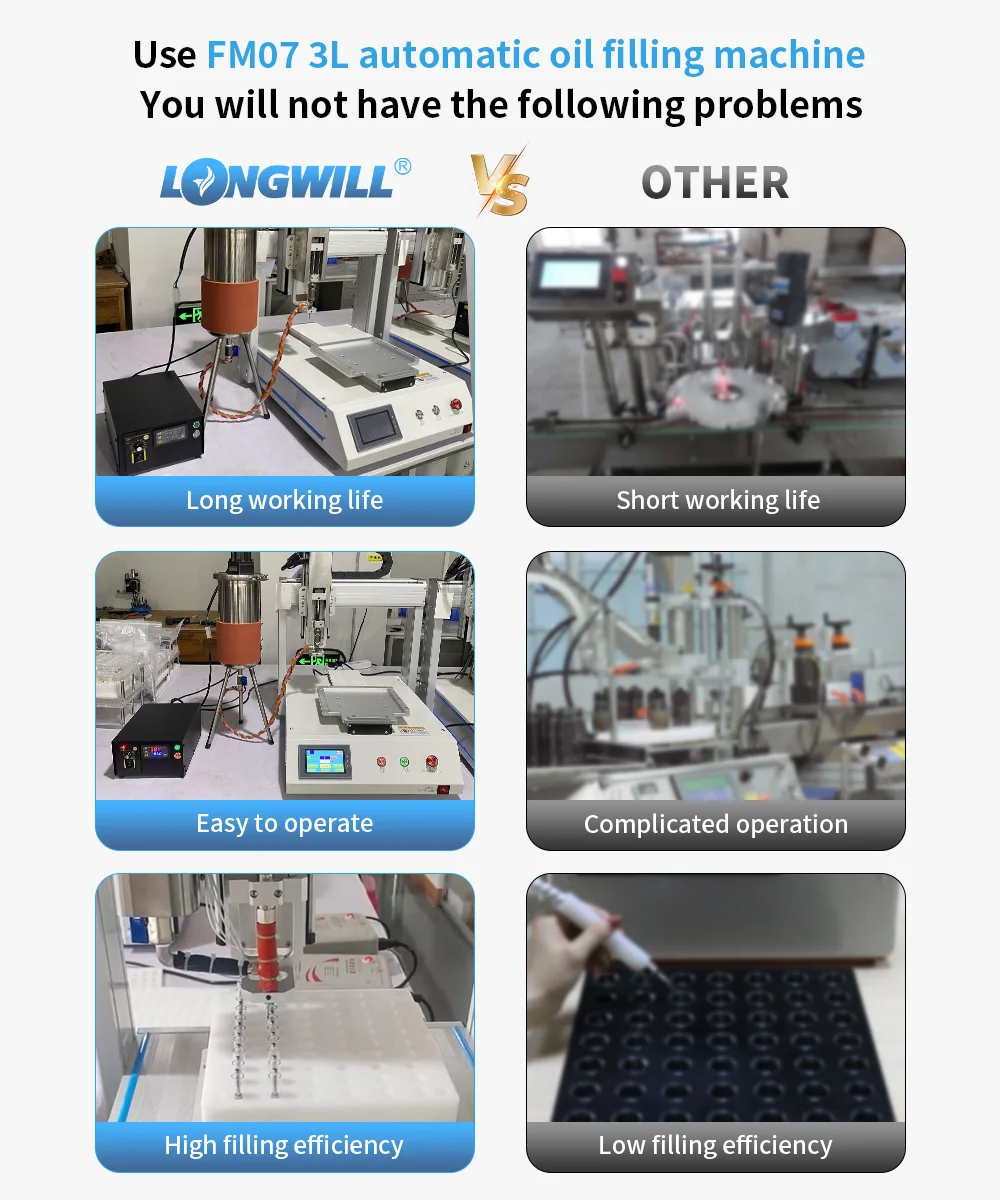

1, Widely used in cartridge industry:

LONGWILL FM-07 Auto Robo cartridge filling machine can be used for Ccell cart, AVD cartridge, 1ml pen, 2ml pen and more;

Some customers also use machine for essential oil tiny bottles filling, like 1ml, 2ml and 5ml etc.;

2, Compatiable with your products:

There is a customized tray for holding your carts pens

and we also program filling system for different carts filling;

3, Efficiency:

Machine can fill 800-1200pcs pen per hour, very efficiency;

4, Heating Control;

Temp is adjustable 0-120celcius, suit for very thick oil filling;

The oil basin and injector part all can be heated to keep oil warm and flow well;

5, Smart Filling System:

Machine has a touch screen, you could set filling volume, filling speed, filling interval, clean procedure etc. all on the screen, very convenient to operate;

Longwill smart filling system is user-friendly, we develop this system by collecting many suggestions from clients, so that operators can read it very easily and handle machine well;

6, Shipment:

Machine can be shipped out in 24-72hours; delivery by DHL take 5-7days, so you will have machine in 6-9days after order;

Machine is packed with film in a wood case, very safe during transportation;

7, Instructions:

There is operation video instruction for your reference, or just call our sales rep for support, we will arrange video call or video call for online support;

8, Quality;

Machine will be tested 9,999 times in working mode and our engineer will check very part carefully;

We will send you machine testing video before shipping;

Machine has 12-month-warranty and life time technical support!

Accessories:

1, 2pcs customized filling trays;

2, Screw tools;

3, Spare Orings and Springs;

4, One box 12pcs needles;

5, Food grade silicon tubes;

6, Paperwork Manual;

7, USB drive with video instructions;

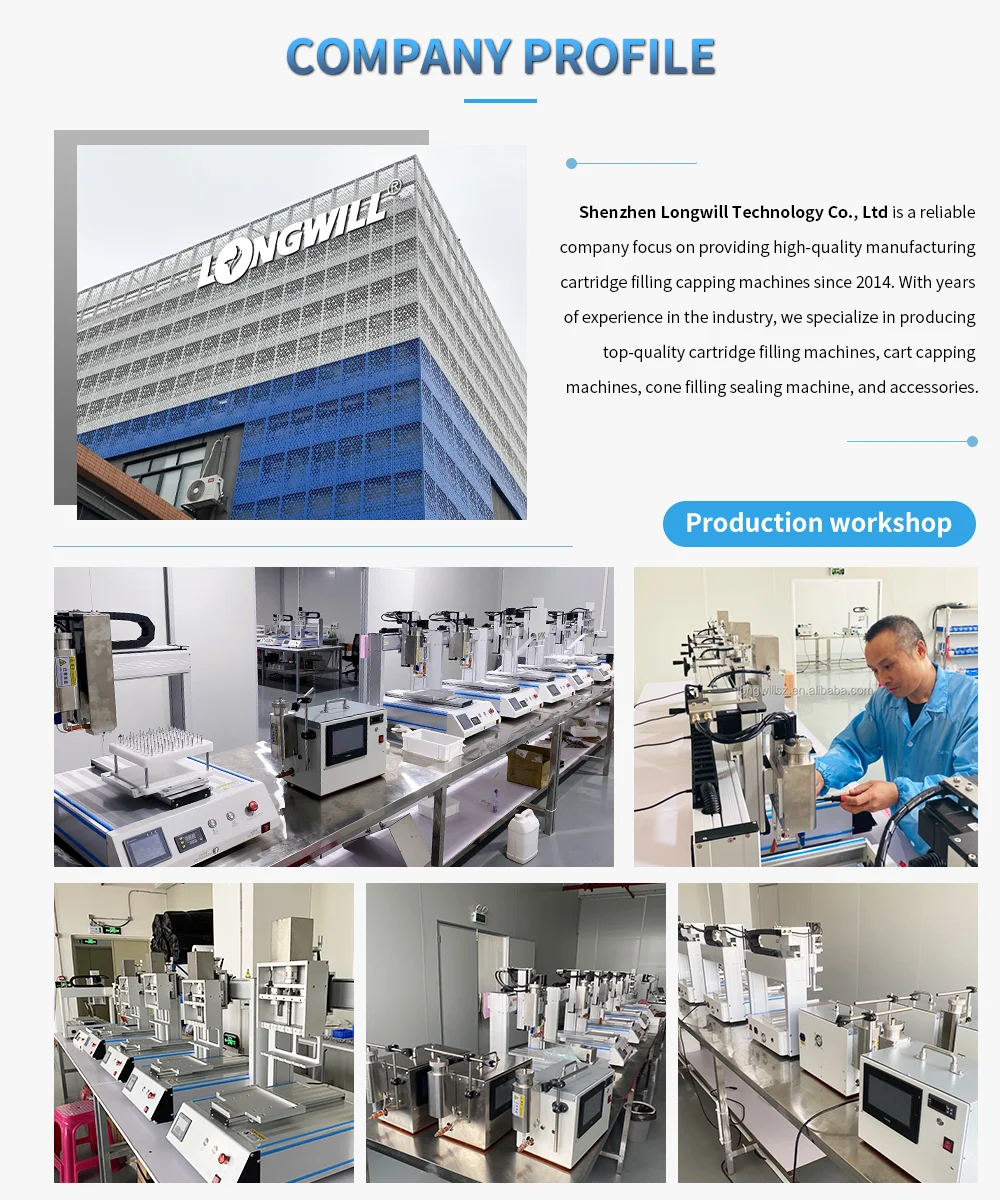

LONGWILL Machine Head Engineer James has more than 20 years filling and packaging machine experience, and he is one of the most professional engineer in China.

He invented the auto filling machine, FM10 smart Filling Machine, and Intelligent Filling and Capping Machine. More machines are in his planning.

“We are here to provide a best solution in filling oil or liquid for clients all over the world. Let filling become an easier work with higher accuracy which help clients save manpower, improve efficiency and save oil.” he said.

LONGWILL team of highly skilled professionals are dedicated to delivering exceptional products and service that exceed our clients’ expectations. Led by James, our Chief Engineer, who has over 20 years of experience in the machinery industry, we are committed to providing innovative and efficient filling and capping solutions to clients worldwide.

All material contacted oil are food grade, safe and healthy, passed testing in USA.

Here are your professional hardware and Filling solution Partner!

Contact me for more clients Filling Feedback video!

SEND INQUIRY NOW FOR SPECIAL COUPONS!

Payment & Shipping

1, Support Kinds of payment, by Alibaba, Paypal, T/T, Western Union etc.

2, Support variety methods of shipments, such as by DHL/Fedex/UPS, by air, by sea, by train door to door.

Why Choose Us

OEM/ODM service:

1,Customize your logo, design your packaging, labelling etc;

2,Function design, redesign the products from the appearance, function and inner structure.

Quality Assurance:

1,Strictly quality control system,we have IQC, IPQC, FQC, OQC etc. to ensure the best quality;

2,Products have passed CE RoHS ASTM certifications to meet the high standards of the local market.

Fast Delivery:

1,Sample order could be shipped in 3-5 days;

2,Bulk order will be shipped in 10-15 days.

Outstanding Service:

1,Excellent Pre-sale,in-sale and after-sale service;

2,We offer 24 hour online service, fast response;

3,All products with life-time sales or service support.

FAQ

Q1: Do you have warranty on machines?

A1: Yes, our machine have 12month warranty, 7*24 hours Online service, Life ti

me technical support, welcome for any question;

Q2: When can I get machine if I place order?

A2: Longwill filling machine can be shipped out in 24-72hours, and 5-7days delivery by DHL!

Q3: Will you support on install machine when receive?

A3: Yes, our sales rep will contact you for online support by video call, or voice call; paperwork instruction and video instruction will be also prepared well;

Q4: Is there any insurance which I pay for to guarantee I will get the right machine?

A4: We are an onsite check supplier from Alibaba. Trade Assurance order provides quality protection, ontime shipment protection and 100% safe payment protection.

Contact me for more clients Filling Feedback video!

SEND INQUIRY NOW FOR SPECIAL COUPONS!

You may ask…

Does My Business Need An Oil Filling Machine?

Whether or not your business needs a oil cart filling machine depends on your company’s current situation and future goals.

Are you currently manufacturing cartridges by hand, or do you have an old manual distillate cartridge filler? If so, it may be time to invest in an automatic oil filling machine to ramp up your production. If you’ve been dragging your feet on buying one, this is a sign that you should take the leap and invest in a cartridge machine.

When you bring a pen cartridge filling machine into your operation, production multiplies by the thousands every single day. If one of your goals has been to increase your cart production, whether because of demand or to break further into the market, a cartridge filling machine can help you achieve that.

The more you produce, the more available on dispensary shelves, the more your brand name circulates in the community.

Investing in a quality oil cart filling machine is one of the smartest decisions you can make as a cartridge manufacturer.

As the modern community clamors for efficient, convenient, and increasingly potent products, us folks in the industry have to shape up or ship out. Automatic or semi automatic cart filling machine make it easy to stay ahead of the game and become more productive than ever.

What Kind of Cart Filling Machine Should I Consider?

If you’re running a smaller-scale operation with a tight-knit, hardworking team, a semi automatic oil cartridge filling machine may be all you need. Longwill FM10 Smart Cartridge filling machine distillate cartridge filler loads up to 8,000 cartridges in a day (depending on the viscosity of your concentrates/the pace you work at) – compared with filling by hand, that’s an unbelievable daily increase.

If you’re running a larger-scale operation, producing multiple products including multiple concentrates/cartridges, an automatic cart filling machine like FM07 Auto Robo Cartridge Filling Machine is pretty much a necessity. Even with dozens of hardworking employees on a cartridge filler line, there’s just no comparison to output – it fills 1,200 cartridges per hour.

If you’re running a large quantity operation, producing more than ten thousands carts in one day, the FC-01 Intelligent Filling Capping Machine and Longwill TM-03 Mouthpiece Twist Cartridge Capping machine will be a best partner. It can fill carts and capping or twisting carts all in one machine, only one worker can hold 12,000 carts filling and capping in one day!

Learn more at LONGWILL Machinery Youtube: https://www.youtube.com/channel/UCOslAMaxSn5ryFVUsBGVu4Q