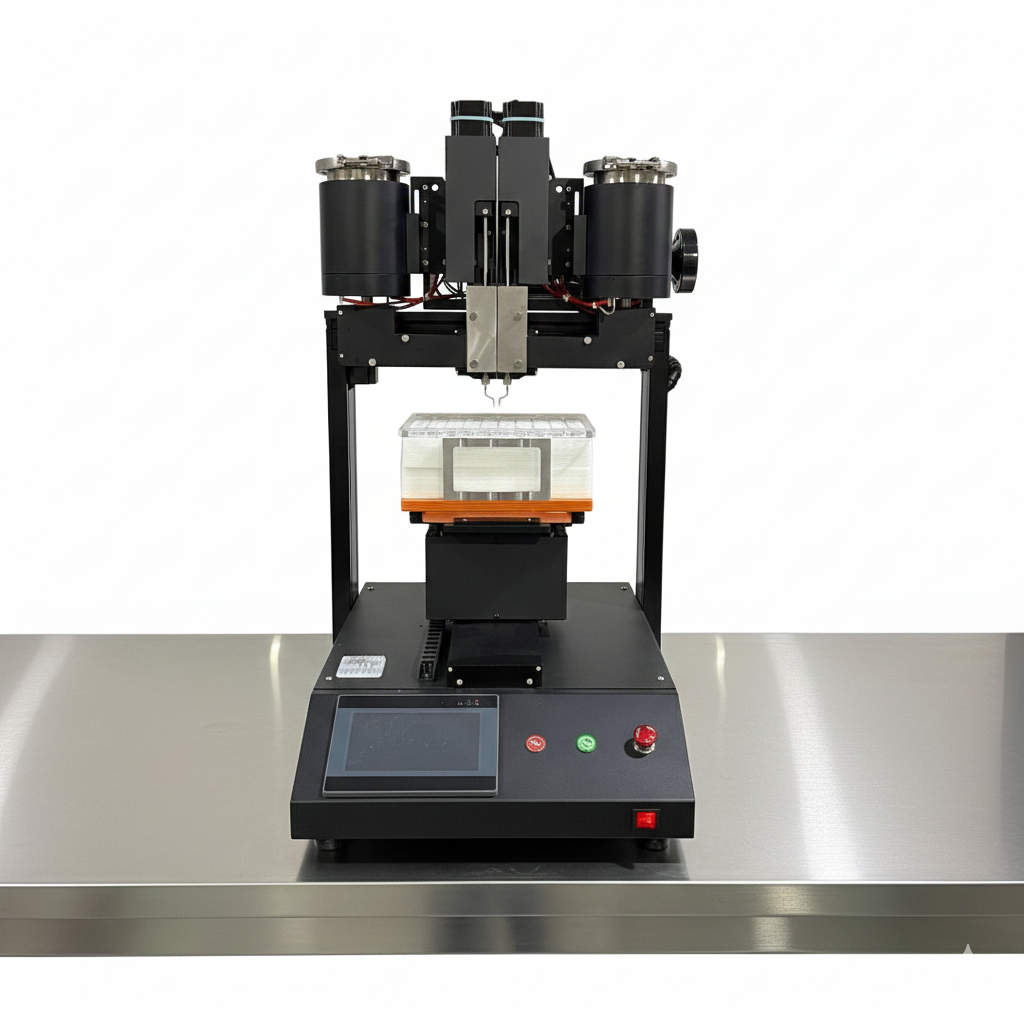

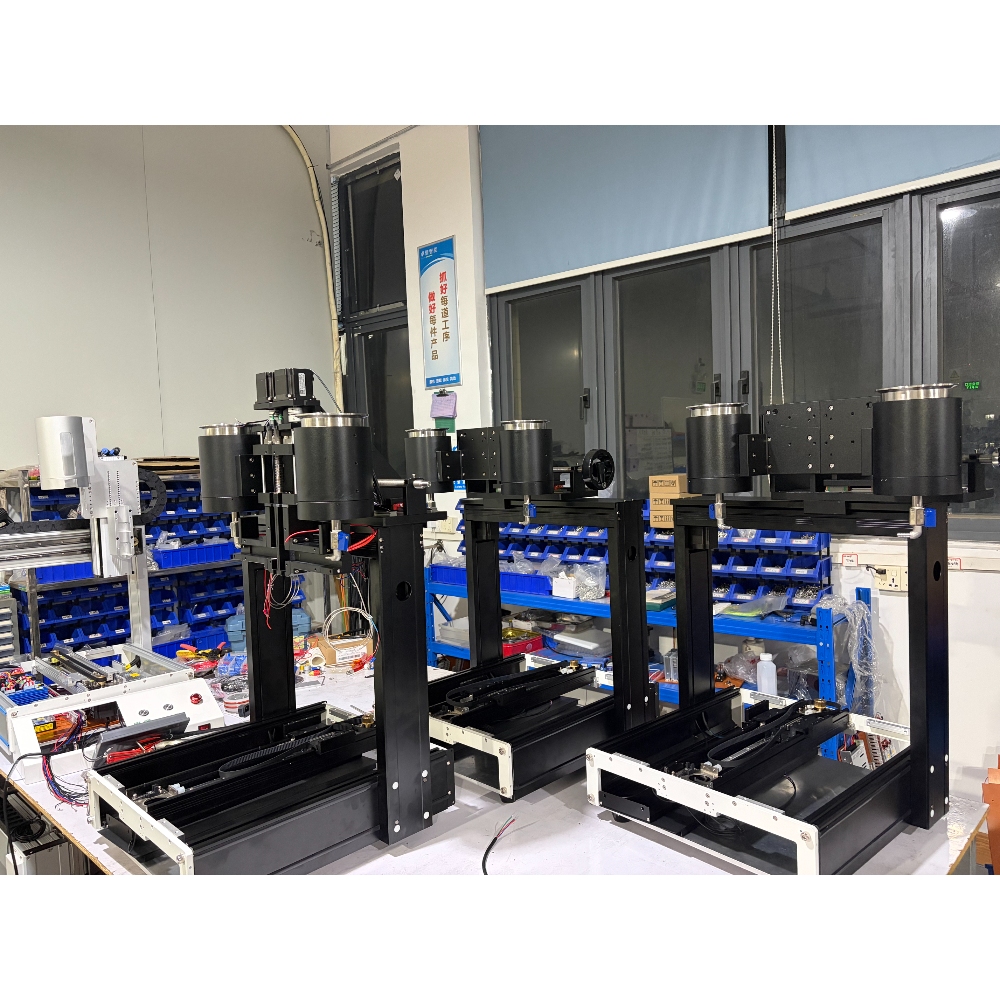

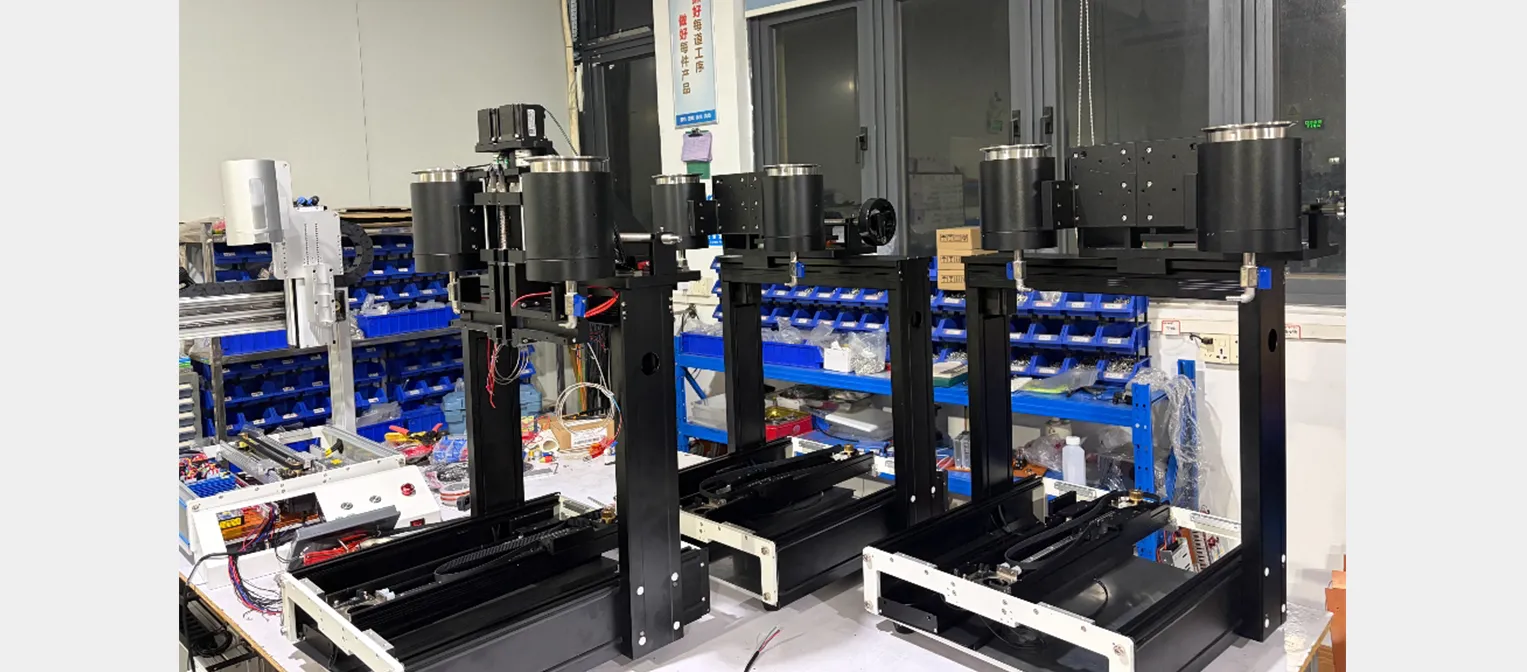

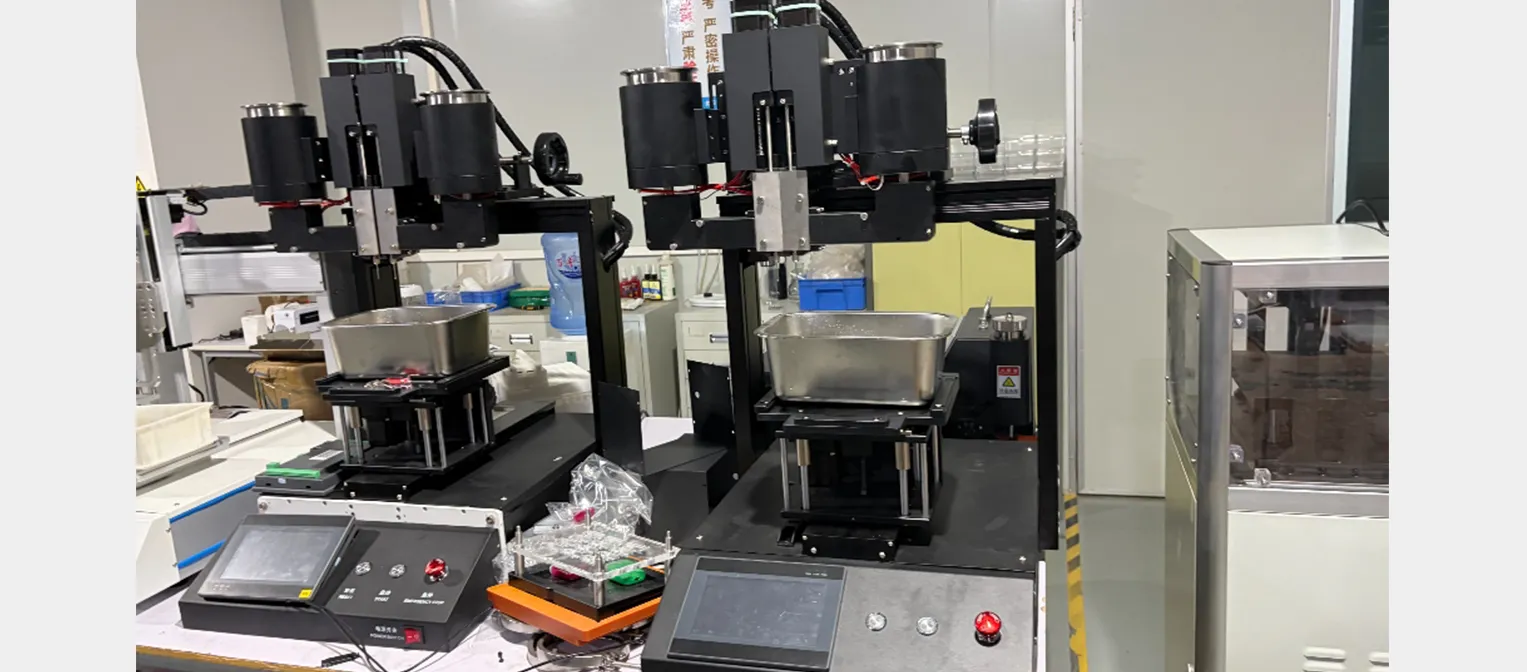

Fully Automatic Dual Oil Tank Cartridge Filling Machine

Amount of oiling: 0.2-5ml + 0.2-5ml

Oil basin: 1000ml + 1000ml

Oil filling accuracy: ±1%

Output: 1600-3000 sticks / hour

Power supply: AC220V/110V

Temperature: 0-120 celsius

| Model | Fully Automatic Dual Oil Tank Cartridge Filling Machine |

| Amount of oiling | 0.2ml-5ml + 0.2ml-5ml; oil basin 1000ml + 1000ml |

| Oil filling accuracy | ±1% |

| Productivity | 1600-3000pcs per hour |

| Voltage | 110V/220V |

| Material | Food grade silicon tube; and lead free injector; FDA testing passed |

| Working system | Longwill smart filling system |

| Drive mode | Stepper motor + rail drive to ensure high accuracy filling |

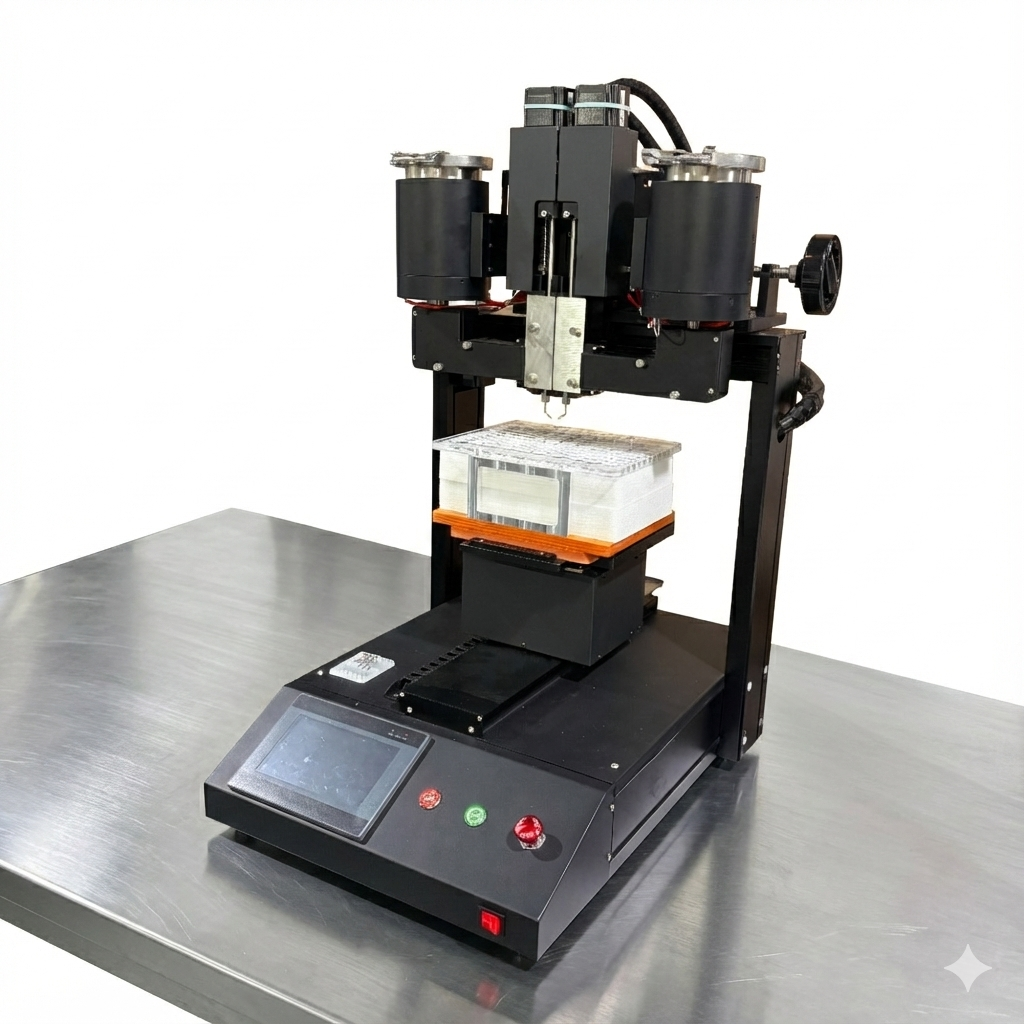

| Panel control | Touch screen easy to read, operation button, very easy to operate |

| Demension & Weight | W*D*H(mm) weight: 580*640*650mm, Total weight about 65kg, Wooden box packaging L*W*H=600*740*1050mm, Total weight 95kg |

| Warranty | 12-month |

| Shipping | DHL/Fedex/ups, by air, by sea, by train door to door. |

| Payment | Support Kinds of payment, by Alibaba, Paypal, T/T, Western Union etc. |

Fully Automatic Dual Oil Tank Cartridge Filling Machine

High-Efficiency Dual Cartridge Filling Machine for Single & Dual-Flavor Vapes

As the CBD and cannabis vape market continues to evolve, cartridge filling equipment must offer both efficiency and flexibility. While dual-flavor cartridges are rapidly gaining popularity, single-flavor products still represent the majority of daily production. Manufacturers are looking for a filling solution that can handle high-volume single-oil production, while also being ready for dual-flavor and dual-formula cartridges.

To meet this demand, Longwill Machinery has developed a Fully Automatic Dual Oil Tank & Dual Nozzle Cartridge Filling Machine—a versatile system designed to support current production needs and future product trends.

One Cartridge Filling Machine, Multiple Filling Modes

This vape cartridge filling machine is designed to adapt to different production scenarios with ease:

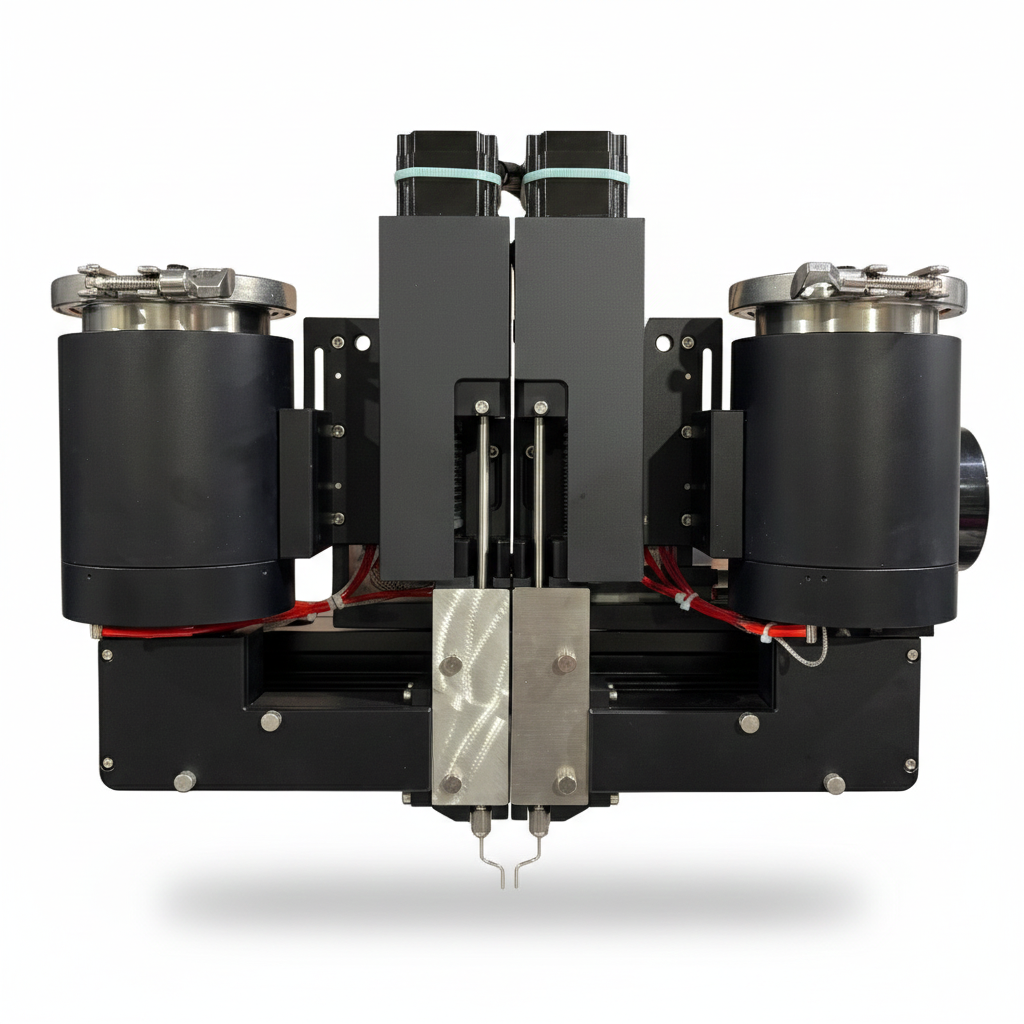

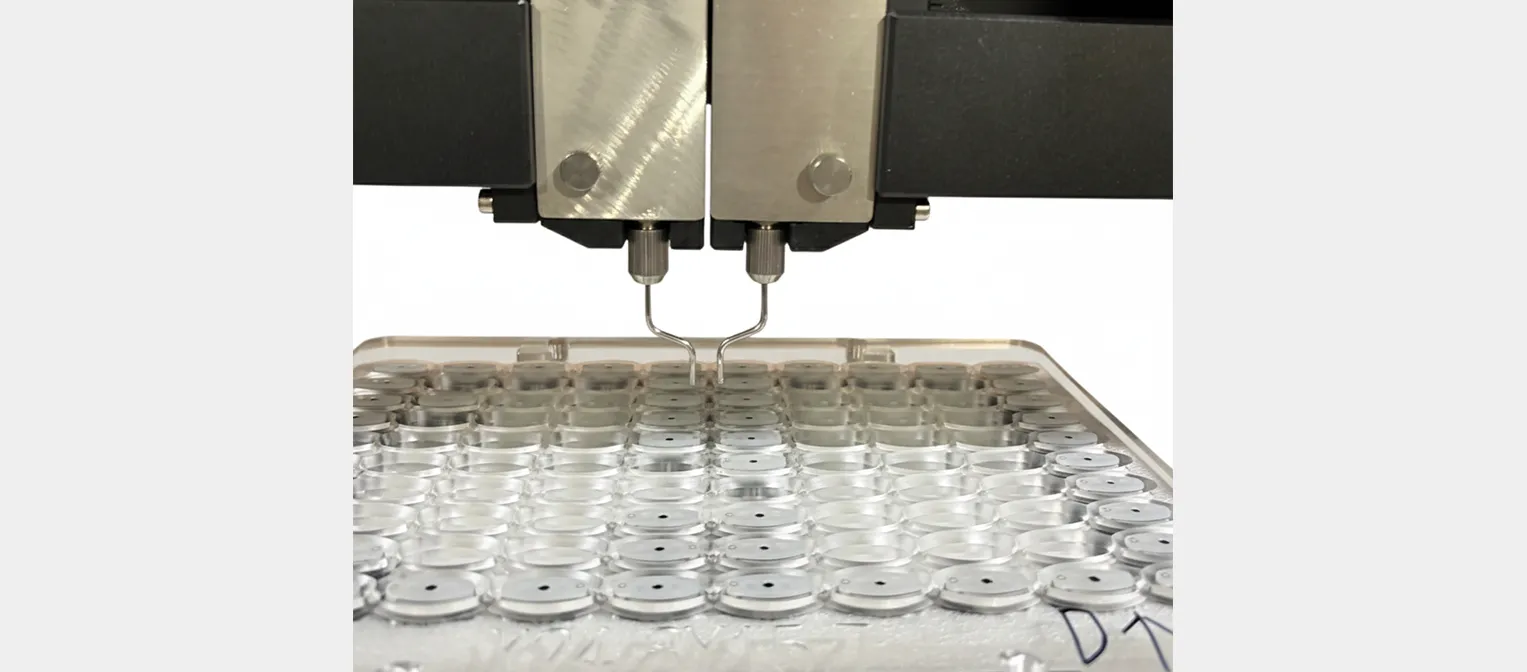

● Single Oil, High-Speed Production

When used as a single-oil filling machine, one oil tank can be activated while the second tank is turned off. This allows the machine to operate as a standard fully automatic cartridge filling machine, significantly improving efficiency for traditional single-flavor cartridges.

● Dual Oil, Single-Flavor Efficiency

Both oil tanks can be filled with the same oil to increase throughput and reduce cycle time, making it ideal for large-volume production where speed and consistency are critical.

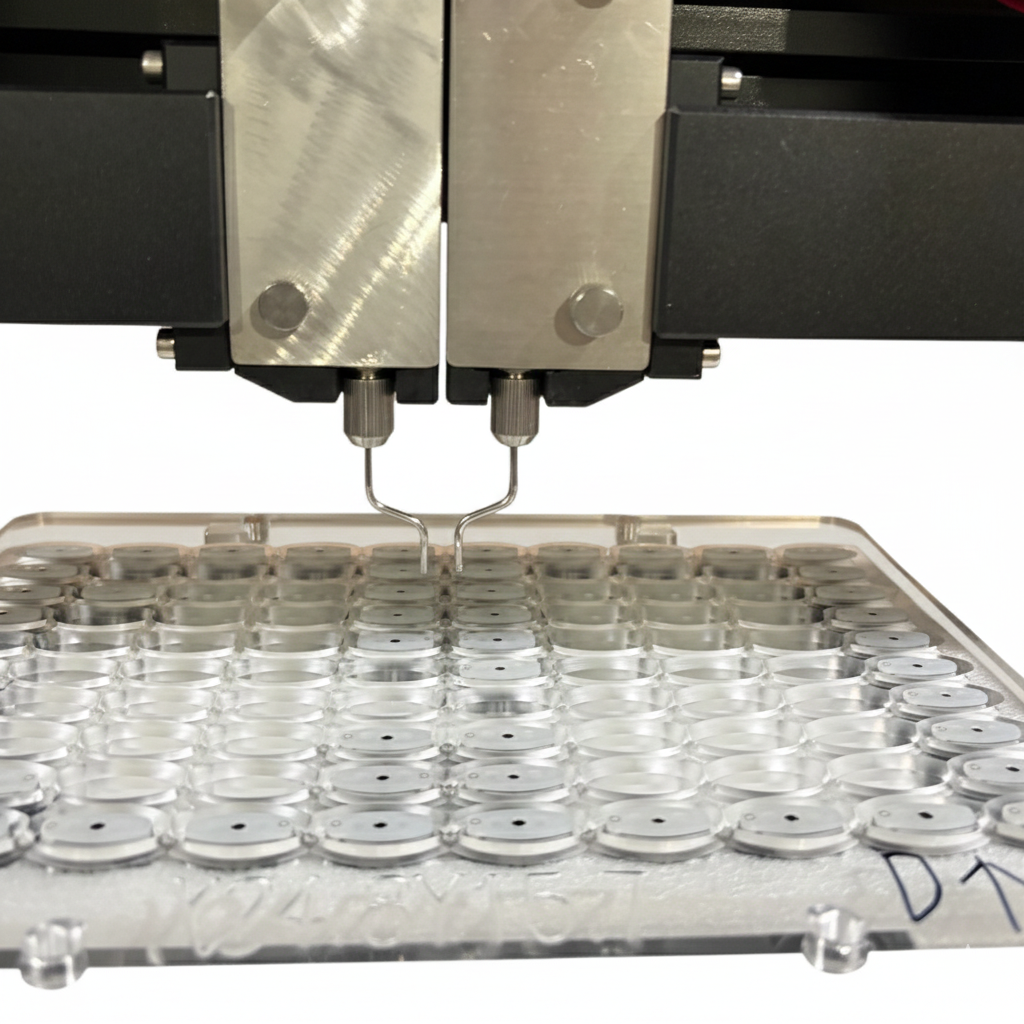

● Dual Oil, Dual Flavor Filling

With two independent oil tanks and two filling nozzles, the filling machine can also be used to fill two different oils into one cartridge, supporting:

Dual-flavor cartridges

Blended cannabinoid formulations

Function-based oil combinations

This flexibility allows brands to respond quickly to market trends without investing in multiple machines.

Designed for the Growing Dual-Flavor Market

Dual-flavor and dual-formula vape cartridge filling machines are becoming a key point of differentiation for CBD and cannabis brands. However, traditional single-oil filling systems are inefficient and prone to cross-contamination when handling multiple oils.

Our dual oil tank design eliminates these issues by:

Keeping oils fully separated

Allowing independent temperature control

Reducing cleaning time between oil changes

Improving consistency and product stability

This makes the cartridge filling machine an ideal solution for brands developing next-generation vape products.

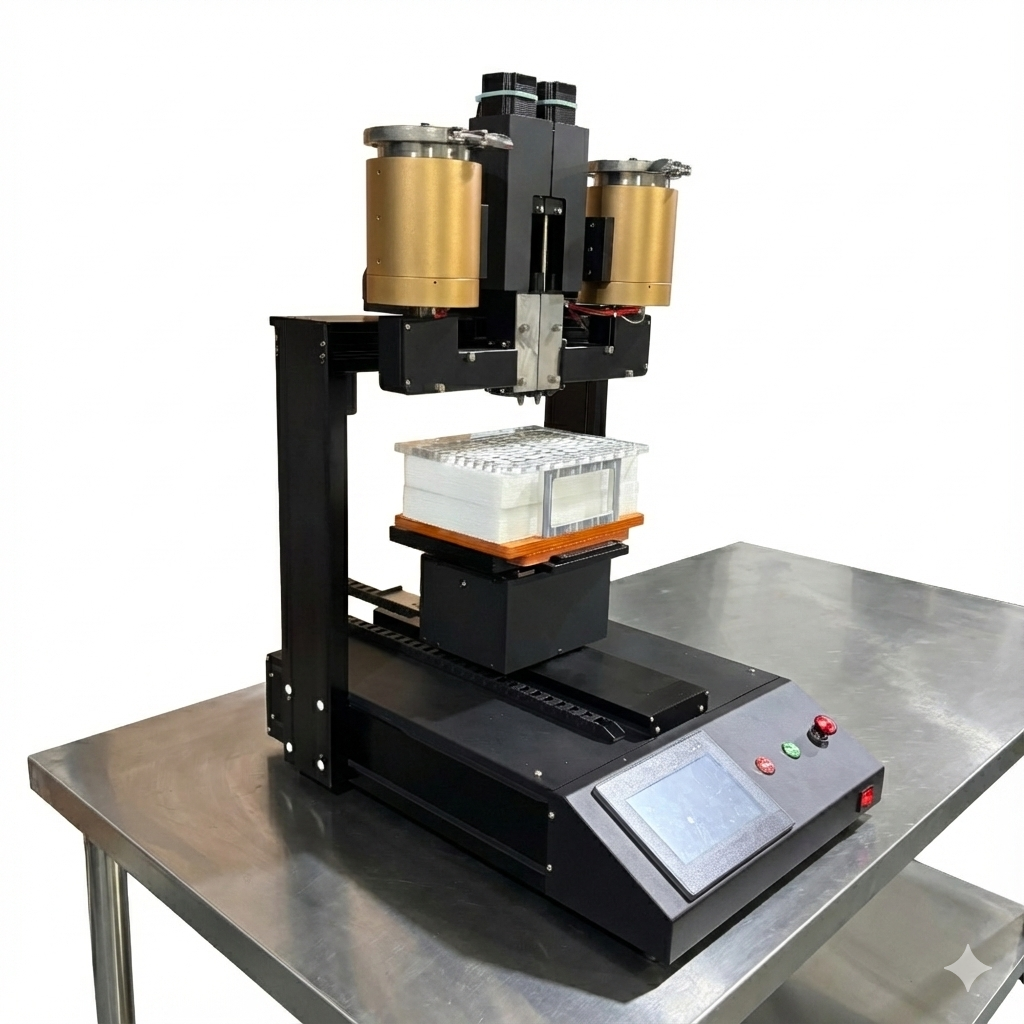

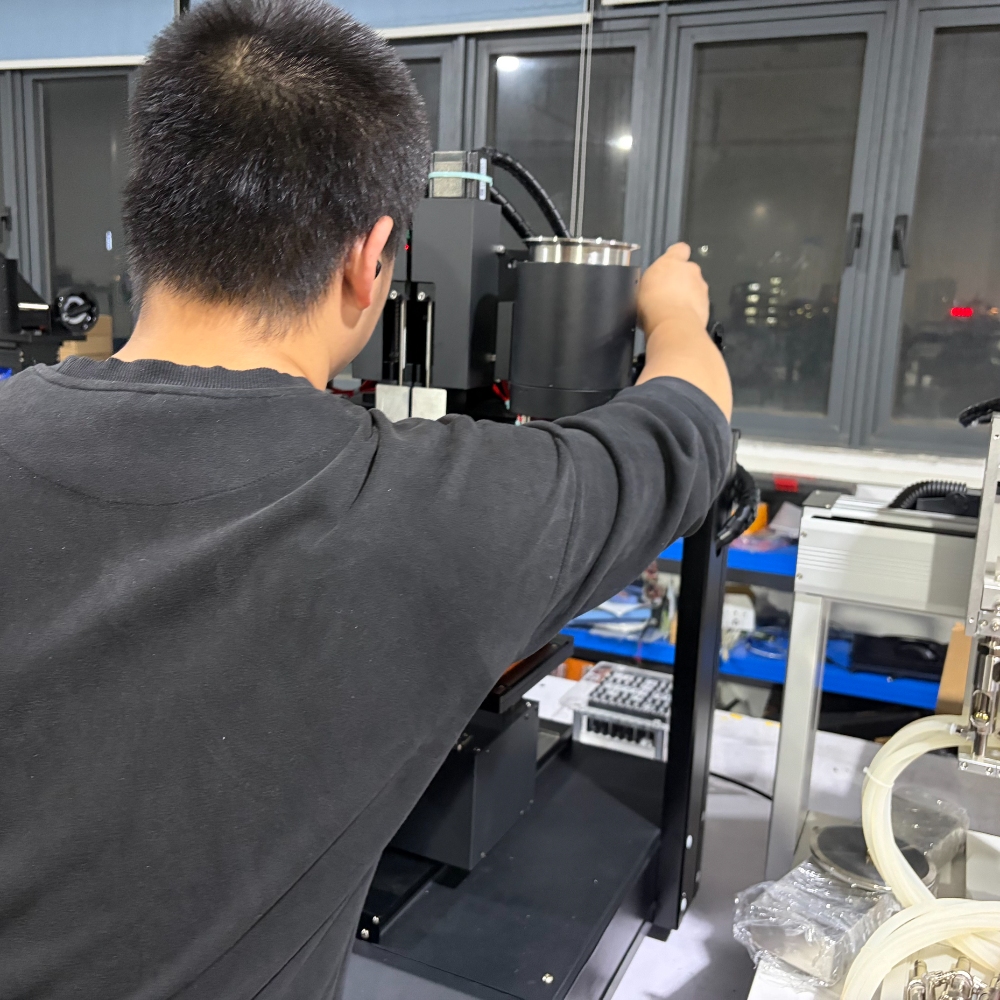

High-Quality, Safe Materials for Cannabis Applications

All material contact components are carefully selected to meet the strict requirements of CBD and cannabis oil filling :

Oil Tanks: SS304 stainless steel

Pumps: SS316 stainless steel

Tubing: Food-grade silicone

All materials comply with FDA standards, ensuring safety, chemical stability, and long-term reliability when handling cannabis oils and terpene-rich formulations.

Precision Filling with Wide Volume Range

Filling Range: 0.2 ml – 5 ml

Filling Accuracy: up to 99%

Stable and repeatable dosing across different oil viscosities

Suitable for standard 510 cartridges and various vape formats

This level of precision helps reduce oil waste, improve batch consistency, and protect overall product quality.

Easy Cleaning & Low Maintenance Design for CBD Oil Bottle Filling Machine

The cbd oil bottle filling machine is engineered for daily production environments:

Modular structure for fast disassembly

Smooth internal surfaces for easy cleaning

Reduced downtime during oil changes

Simple maintenance without complex tools

This design is especially valuable for manufacturers running multiple SKUs or frequent formulation changes.

Certified for Global Markets

To support international customers, the cbd oil bottle filling machine is fully certified:

CE Certified

FCC Certified

Materials compliant with FDA standards

This ensures smooth importation, compliance with regulatory requirements, and confidence for customers operating in regulated markets.

Ideal For

CBD and cannabis vape cartridge manufacturers

Brands producing both single and dual flavor products

High-volume production lines seeking flexibility

Companies preparing for future dual-oil product trends

Built for Today’s Production — Ready for Tomorrow’s Innovation

The Fully Automatic Dual Oil Tank Cartridge Filling Machine is not just a solution for today’s production challenges—it is a strategic investment for brands looking to stay ahead in a rapidly changing vape market. By combining efficiency, flexibility, and safety, this filling machine allows manufacturers to scale confidently while embracing the future of dual-flavor cartridge development.