Choosing the Best Vape Cartridge Filling Machine

This guide breaks down everything you need to consider when choosing the best vape cartridge and the right equipment to fill it.

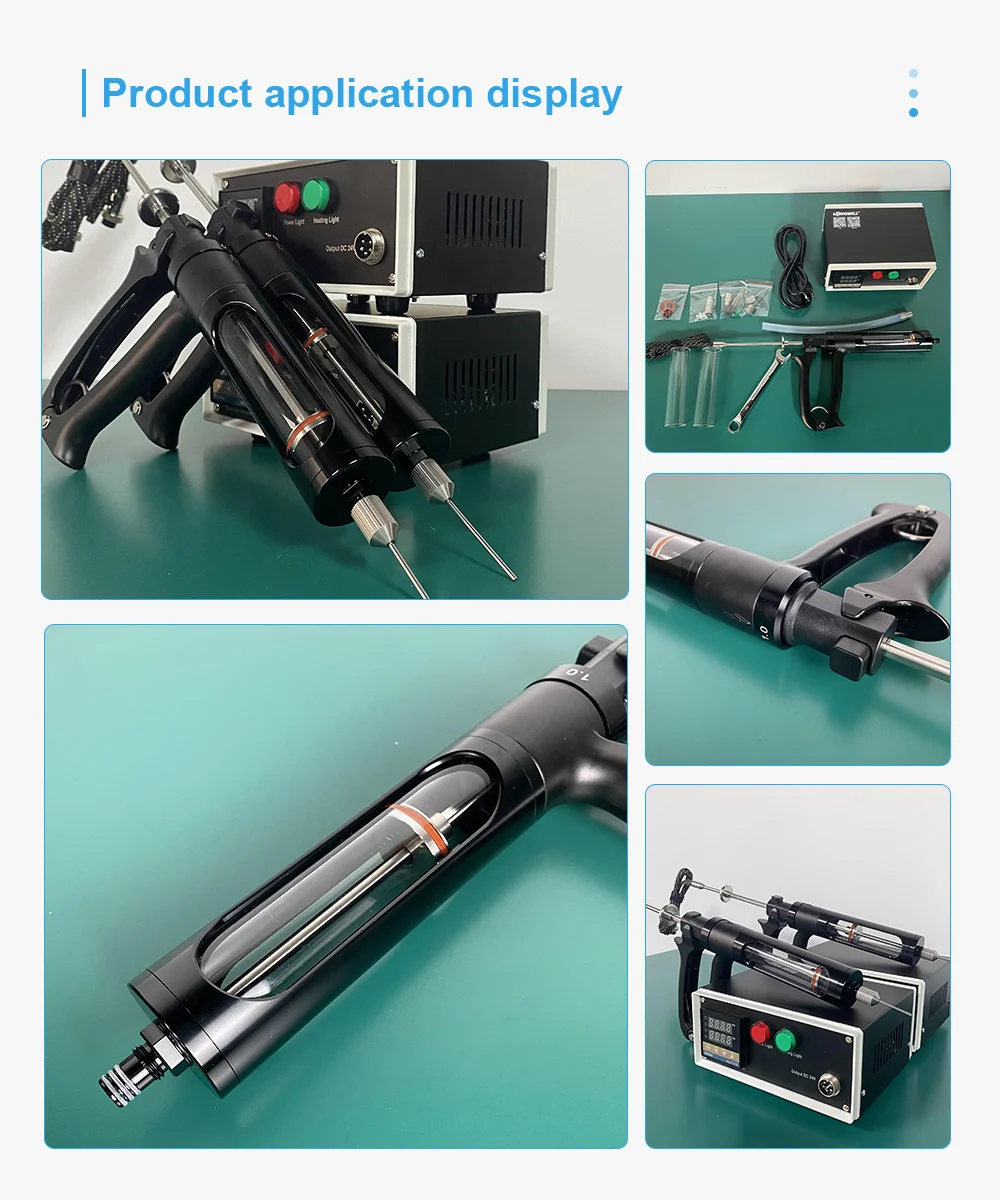

1. What Is the Best Quality Vape Cartridge Filling Machine?

Before selecting a vape cartridge filling machine, it's important to first understand what defines a high-quality vape cartridge. The cartridge is not just a container—it plays a crucial role in both the user experience and the production process. A reliable cartridge ensures smooth vapor delivery, reduces material loss, and allows your filling line to operate efficiently with minimal waste or rework.

Key Attributes of a Premium Vape Cartridge

1.1 Medical-Grade and Chemically Stable Materials

High-quality cartridges are made from materials that can withstand the unique demands of cannabis extracts. These typically include borosilicate glass, food-grade stainless steel, and BPA-free medical-grade polymers. Such materials provide excellent chemical resistance against cannabinoids, terpenes, and other active compounds, ensuring long-term product safety, stability, and regulatory compliance.

1.2 Efficient and Clean Heating Technology

A reliable vape cartridge filling machine should incorporate advanced ceramic coil technology, which has become the industry standard for its ability to deliver even heating and preserve flavor profiles. Unlike traditional wick systems, ceramic cores are better suited for high-viscosity oils such as CBD distillate or live resin. They also help minimize burnt hits, oil buildup, and coil clogging—issues that can negatively affect user satisfaction and cause product complaints.

1.3 Leak-Resistant, Tamper-Proof Engineering

To maintain product integrity through shipping, storage, and use, top-tier cartridges are designed with precision seals, reinforced joints, and secure closure systems. Common features include snap-lock or press-fit mouthpieces that help prevent leaks and tampering. These elements not only safeguard the oil but also enhance shelf stability and reduce the likelihood of costly returns.

1.4 Standardized 510 Thread Interface

The 510-thread format is widely adopted across the vape industry for its universal compatibility with most batteries and filling machines. This thread type allows manufacturers to standardize their processes across different product lines, simplifying automation and minimizing the need for tooling changes. Choosing 510-compatible cartridges also makes your product more accessible to a broader consumer base.

1.5 Thermal Durability During Filling

Cartridges are frequently exposed to elevated temperatures during the filling process—especially when working with thick oils that require heating to flow properly. A high-performance cartridge should retain its structural integrity under heat, resisting deformation, leaks, or cap misalignment. This ensures that the cartridge remains functional and presentable throughout production, packaging, and usage.

Want to keep your filling machine running at peak performance? Check out our guide on How to Clean and Maintain a Vape Cartridge Filling Machine to extend equipment life and ensure consistent output.

https://longwillmachinery.com/how-to-clean-and-maintain-a-vape-cartridge-filling-machine.html

2.Key Features to Consider in a CBD Vape Filling Machine

Feature | Description |

High-Precision Dosing | ±1% fill accuracy for consistent oil volume |

Integrated Heating | Even heating in tank, tubes, and nozzles for thick oils |

Cartridge Compatibility | Supports 510 carts, AIOs, and custom formats |

Automation Level | Semi-auto or full-auto options based on production scale |

Touchscreen Control | Easy setup with presets and real-time monitoring |

Easy Maintenance | Tool-free cleaning and food-grade components |

After selecting a vape cartridge that meets your quality and branding standards, the next critical decision is choosing a cbd vape filling machine that can support your production goals with precision, consistency, and minimal waste. The ideal system should not only handle various oil types but also streamline your operations without compromising product quality or efficiency.

Here are the essential features that define a high-performance vape cartridge filling system:

2.1 Precision Dosing for Consistent Output

Accurate oil dosing is essential—particularly when working with premium cannabis extracts like CBD distillates or high-terpene formulations, where product value and compliance standards are high. Leading machines achieve ±1% dosing accuracy, ensuring each cartridge, whether 0.5ml or 1ml, is filled with exact uniformity. This consistency helps maintain product integrity, supports regulatory requirements, and reduces unnecessary material loss over time.

2.2 Advanced Heating Integration for High-Viscosity Oils

Viscous substances such as rosin, live resin, and full-spectrum oil require controlled, consistent heat to flow properly during the filling process. Look for machines with evenly distributed heating systems across tanks, hoses, and nozzles. This design helps prevent cold spots, clogging, and inconsistent flow, while also preserving the potency and stability of sensitive cannabinoids and volatile terpenes.

2.3 Flexible Cartridge Compatibility

Modern production lines often involve filling more than one type of cartridge—such as 510-thread carts, disposable pens, or all-in-one (AIO) devices. A reliable machine should support tool-less fixture changes and adjustable nozzles, enabling smooth transitions between formats with minimal downtime. This flexibility ensures you can adapt quickly to new market demands or SKU expansions without overhauling your equipment.

2.4 Scalable Automation Options

The right level of automation depends on your operational size and future expansion plans:

Semi-automatic filling machines are ideal for craft-scale or specialty production, offering more manual control for R&D and low-volume runs.

Fully automatic filling machines, on the other hand, are designed for large-scale output and often include integrated systems for auto-capping, conveyor movement, and even batch traceability.

Aligning machine automation with your workflow needs can greatly impact labor efficiency, cost savings, and production capacity.

For small-batch production or pilot testing, explore our Top-Rated Semi-Auto CBD Cartridge Filling Machine—designed for precision, consistency, and easy operation.

2.5 Intuitive Control Interface

Ease of operation is key to minimizing human error and speeding up changeovers. Advanced filling machines are equipped with user-friendly touchscreen interfaces (HMIs) that allow operators to:

Select saved filling programs

Adjust parameters in real-time

Monitor system diagnostics and flow performance

This smart interface simplifies onboarding and gives operators better control across multiple product types or shifts.

2.6 Sanitation and Maintenance Efficiency

Frequent cleaning and maintenance are part of any filling operation—but the process shouldn’t slow you down. Choose systems designed for quick disassembly, with food-grade wetted components and automatic flush cleaning cycles. This design not only reduces changeover time between different oils but also limits contamination risk—crucial for maintaining product safety and operational hygiene.

2.7 Why These Features Are Critical

A vape cartridge filling machine is more than a mechanical investment—it's the core of your production efficiency, product consistency, and long-term scalability. By focusing on dosing accuracy, thermal control, multi-format compatibility, and operator-friendly features, you ensure your filling line is prepared to evolve with changing product trends and consumer expectations.

Whether you're launching a boutique vape line or expanding a high-volume production facility, choosing the right system today sets the foundation for consistent output, reduced waste, and sustainable growth in a highly competitive market.

3.How Do I Choose the Best Vape Cartridge Filling Machine?

Selecting the right vape cartridge is a strategic decision that impacts not only product performance, but also operational efficiency, consumer perception, and regulatory compliance. The cartridge serves as the final touchpoint between your oil and the end user, and any failure in its design or compatibility can undermine even the highest-quality formulation.

3.1 Oil Behavior: Viscosity, Stability, and Flow Dynamics

Understanding your oil's behavior under real-world production and use conditions is crucial to selecting the right vape cartridge. Oils vary widely in viscosity, thermal reaction, and volatility—factors that influence flow, dosing precision, and vapor performance.

Thicker concentrates like live rosin or high-terpene extracts typically need cartridges with expanded intake apertures, ceramic heating elements, and optimized airflow architecture to maintain vapor quality and prevent clogging. By contrast, lower-viscosity oils such as broad-spectrum CBD distillates require tight seals and internal precision, as they are more prone to leaking or evaporating over time if the design isn’t precise.

Moreover, many oils are heat-sensitive and can expand slightly when warmed during the filling process or during use. That makes thermal durability essential. A well-engineered cartridge should maintain shape and function under elevated temperatures without softening, warping, or compromising the oil's chemical integrity.

3.2 Material Integrity and Regulatory Compliance

As the legal landscape for cannabis products continues to mature, particularly in North America and Europe, regulatory expectations for hardware safety and manufacturing transparency are higher than ever. Poor material choices or unverified manufacturing processes can jeopardize product approvals and damage brand credibility.

To align with compliance standards, prioritize cartridges made from certified, medical-grade materials—such as borosilicate glass, 316L stainless steel, and non-toxic polymers. These components resist chemical interactions, tolerate heat, and ensure a neutral vapor path for consumers.

Equally important is the facility behind the cartridge. Reliable products should come from ISO 9001 or GMP-certified production lines, where documented quality procedures are consistently followed. Supporting materials—like MSDS sheets, lab reports, or compliance declarations—further streamline regulatory filings and provide confidence across retail and distribution channels.

3.3 Visual Design and Brand Presentation

Beyond function, the cartridge’s visual impression can have a significant impact on consumer appeal—especially in saturated or premium markets. A refined exterior isn’t just a cosmetic bonus; it signals product quality and reflects brand identity.

Look for design elements that showcase product clarity and integrity. Transparent tanks, for instance, allow buyers to assess oil quality visually. Metallic finishes, anodized hardware, or custom-colored components elevate shelf presence. For brand cohesion and protection, features like engraved logos, batch numbers, or tamper-evident closures reinforce professionalism and consumer trust.

When design aligns with performance, cartridges become more than delivery tools—they become a strategic part of your product's value proposition.

3.4 Compatibility with Filling Systems

Cartridge selection isn’t just about consumer use—it must also work seamlessly with your production environment. Overlooking mechanical compatibility with your filling equipment can lead to operational inefficiencies, product damage, or even increased rejection rates.

Each cartridge must align precisely with your machine's nozzle size, fill head stroke length, and seating mechanism. Mismatched components can result in underfills, spillage, or wear on expensive hardware. You’ll also want to ensure your capping system—whether it's press-fit, screw-on, or ultrasonic sealing—matches the cartridge design, avoiding additional labor or retooling.

For automated workflows, precise alignment within fixtures or jigs is critical. A cartridge that doesn't seat consistently can halt your line, reduce yield, or lead to batch contamination. Pre-validating cartridge compatibility with your equipment reduces production risk and preserves throughput.

3.5 Supplier Reliability and Product Consistency

Even the best-designed cartridge becomes a liability if the supply chain behind it is unstable. Fluctuating quality, late shipments, or unresponsive service can disrupt production cycles and damage business relationships.

Look for suppliers that demonstrate not only volume capacity, but also consistent quality standards across batches. Key indicators include low rejection rates, tight dimensional tolerances, and responsive technical support. These capabilities are particularly vital during high-demand periods when reliability can make or break a launch window.

Moreover, robust documentation—such as lot tracking, pre-shipment inspection reports, and compliance certificates—is a sign of a well-managed manufacturing partner. Long-term partnerships depend not just on price or speed, but on predictable, repeatable quality that supports scale and protects your product reputation.

Learn more:

https://longwillmachinery.com/what-to-know-before-buying-vape-cartridge-filling-machines.html

https://longwillmachinery.com/top-5-cbd-cartridge-filling-machines-in-2025.html

https://longwillmachinery.com/thc-vs-cbd-cartridge-filling-machines-key-differences-2025.html

Conclusion

Selecting the right vape cartridge and filling system isn’t just a technical decision—it’s a strategic investment in your brand’s performance and long-term success.