Types of Cannabis Vape Cartridge Filling Machines

In this guide, we break down the main types of vape cartridge filling machines—manual, semi-automatic, and fully automatic—along with the key buying considerations, emerging trends, and practical recommendations for 2025. The goal is simple: help you match your production reality and growth plans with equipment that actually fits your operation.

Table of Contents

Manual Cannabis Vape Cartridge Filling Machines and Equipment

Semi-Automatic Cannabis Vape Cartridge Filling Machines

Fully-Automatic Cannabis Vape Cartridge Filling Machines

What Else to Consider When Shopping for a Cartridge Filling Machine

Emerging Gaps & Trends

What to Choose (2025 Recommendations)

Still not sure what type of filling machine is right for your operation?

Manual Cannabis Vape Cartridge Filling Machines and Equipment

Manual vape cartridge filling machines are often the starting point for smaller cannabis operations — perfect for R&D labs, boutique extractors, or brands that are just beginning to produce vape cartridges. These setups typically use heated syringes, handheld dosing tools, manual plungers, or compact benchtop units built for lower-volume production.

Advantages:

Most budget-friendly option for startups and small-batch producers

Great for limited runs, specialty drops, and frequent product rotation

Very versatile — compatible with CCell, 510-thread cartridges, and many disposable formats

Simple, intuitive workflow that requires minimal operator training

Limitations:

Output is relatively low — typically around 100–500 cartridges per hour, depending on the operator

Fill volumes can be inconsistent when they depend heavily on manual technique

Repetitive, hands-on work can be tiring during longer shifts

It’s harder to keep oil at the ideal temperature, especially with thick distillate, live resin, or rosin

Where Manual Systems Shine:

Small experimental runs or pilot batches

New product development and formulation trials

Handling high-viscosity extracts where close attention and gentle processing matter

Operations that emphasize craft quality over raw volume

For very small teams or brands still validating their products, manual vape cartridge filling machines offer a low-risk way to get started without over-investing in automation.

Semi-Automatic Cannabis Vape Cartridge Filling Machines

Semi-automatic vape cartridge filling machines sit right between simple manual tools and fully automated lines. They usually combine a heated reservoir with a precision-driven pump or dispensing system, while an operator triggers and manages the fill cycle. For many producers, this is the first real step into scaled, repeatable production.

Advantages:

Consistent, accurate dosing across medium to large batches

Noticeable boost in productivity — often around 800–2,000 cartridges per hour

Better temperature control helps preserve the quality of distillate and live resin

Fewer issues with leaks, clogs, and cartridge blowouts

Works with a wide variety of cartridges and device formats

Limitations:

Higher upfront investment compared to basic manual tools

Still relies on staff to load, position, and move cartridges

Cleaning the system and switching between different oils or strains can slow things down

Ideal Applications:

Brands moving from small-batch to regular, ongoing production

Facilities that fill both disposable vapes and traditional 510 cartridges

Teams wanting higher efficiency and consistency without committing to a fully automated line

Operations where dose accuracy, repeatability, and product quality are non-negotiable

For many cannabis businesses, semi-automatic vape cartridge filling machines become the workhorse of the production floor — fast enough to scale, flexible enough to adapt.

Fully-Automatic Cannabis Vape Cartridge Filling Machines

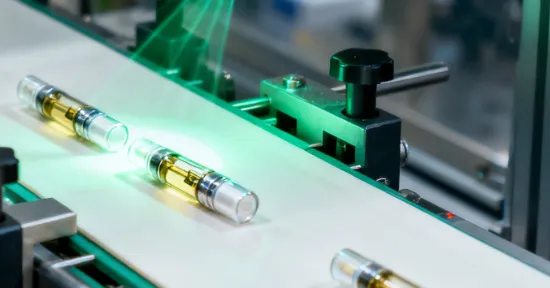

Fully automatic vape cartridge filling machines provide an end-to-end production solution. These platforms often integrate cartridge feeding, orientation, automated filling, capping/torquing, in-line quality checks, and conveyor or turntable handling, all designed to support high-volume, professional manufacturing.

Built for large-capacity producers, fully automated lines can turn cartridge production into a streamlined, low-touch, high-throughput workflow.

Advantages:

Extremely high output — commonly 4,000 to 12,000+ cartridges per hour, depending on the setup

Significantly lower labor cost per unit

Very tight control over fill accuracy and consistency

Well-suited for facilities working toward GMP or pharma-style production standards

Reduces contamination risk and variability by minimizing human contact

Limitations:

Highest capital investment of all machine types

Requires operators and technicians with proper training

Setup, calibration, and product changeovers are more complex and can take longer

May not be cost-effective for brands with irregular or fluctuating production volumes

Best Fit For:

High-output extraction labs with steady, large orders

Multi-state operators (MSOs) scaling up production across multiple markets

OEM/white-label manufacturers producing for several different brands

Facilities regularly turning out 100,000+ cartridges or disposables per week

At this level, fully-automatic vape cartridge filling machines aren’t just equipment — they’re core infrastructure for serious, large-scale cannabis manufacturing.

What Else to Consider When Shopping for a Cartridge Filling Machine

Consideration | Key Points |

Oil Viscosity & Formulation | Thick distillate needs strong, stable heating; live resin/rosin can degrade at high temperatures; CBD oils are usually easier to fill. |

Cartridge Compatibility | Machine should work reliably with CCell, 510-thread carts, plastic or glass tanks, ceramic cores, and disposable all-in-one devices. |

Temperature Control | Look for multiple heating zones, stable temperature over long runs, and good control of viscosity as the oil warms. |

Dosing Precision | Fill weight should be very consistent — even being off by 0.02 g per cartridge can add up to a big loss at scale. |

Cleaning & Changeover Time | Easy to disassemble and clean; efficient when switching strains, terpene blends, or oils with different viscosities. |

Scalability | The machine should keep up with your growth; avoid systems that will be too small or limiting within 6–12 months. |

Emerging Gaps & Trends

1. Rise of Disposable Vapes Over 510 Carts

The market is moving quickly from traditional 510 carts toward disposable vapes, and that shift has a direct impact on the kind of vape cartridge filling machine you actually need.

On the consumer side, disposables are everywhere — people even talk about refilling them to save money, which shows how widely they’re being used. But from a production standpoint, disposables are very different from standard 510 cartridges: they have tighter internal spaces, built-in batteries, and different filling ports and tolerances.

Because of this, a filling setup designed only around 510-thread cartridges can soon become a constraint. That’s why modern vape cartridge filling machines are being built to handle multiple device types — from classic carts to disposables — with quick, simple changeovers.

For any brand entering or expanding in the disposable vape segment, the key question is no longer just “Can this machine fill cartridges?” but rather “Can this machine reliably fill both cartridges and disposables, and switch between them without disrupting our workflow?”

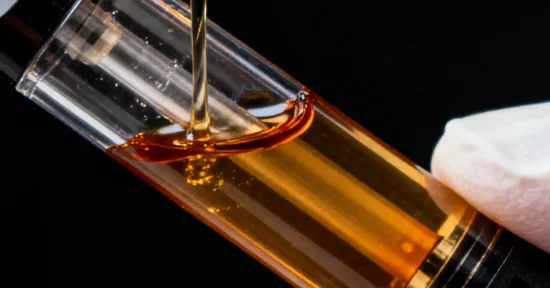

2. Demand for Lower-Temperature Rosin & Resin Filling

As solventless and terp-rich products like rosin and live resin gain momentum, they’re also raising the bar for what a vape cartridge filling machine has to do. These oils are thicker, more heat-sensitive, and far less forgiving if you push the temperature too high — flavor drops off, terpenes burn off, and hardware can gunk up quickly.

That’s why precise, low-temperature control is becoming a must-have rather than a nice-to-have. A good machine should be able to work within a carefully controlled temperature range, keep the oil flowing smoothly, and still maintain high filling accuracy (for example, around ±0.01 ml per shot). When you add in reduced bubble formation and gentle handling, you get cartridges that actually live up to the “premium” claim on the box.

For brands focused on high-end resin or live resin vapes, the question isn’t just “Can this fill thick oil?” It’s “Can this vape cartridge filling machine protect my flavor, my terpenes, and my reputation as a premium product?” That’s exactly where low-temp, high-precision systems stand out from more basic filling gear.

3. Mini Automation Modules

A lot of small and mid-sized vape brands aren’t ready to jump straight into a massive, fully automated production line. Instead, they’re looking for a middle ground: modular automation that grows with them. This is where semi-automatic vape cartridge filling machines shine.

In a semi-auto setup, the operator still triggers and manages the cycle, but the machine takes over the critical parts — dosing, heating, and consistency. It’s ideal for small to medium batches, multiple SKUs, and operations that are scaling but not yet at “factory” level. You get most of the benefits of automation (better speed, better repeatability, less fatigue for staff) without the huge upfront cost or complexity of a full line.

For many growing brands, it makes far more sense to start with a solid semi-automatic vape cartridge filling machine, then add modules or upgrade later, rather than overspending on a system they won’t fully utilize for years.

4. Real-Time Filling Analytics

As operations become more professional and more regulated, producers are realizing that it’s not enough for a machine to “feel” accurate — they need proof. Modern vape cartridge filling machines increasingly come with touch-screen interfaces, fine dosing control, and the ability to monitor fill performance in real time.

Being able to see how much you’re filling, how consistent each shot is, and how a batch is performing over time turns filling from a blind process into a measurable one. That kind of visibility makes it easier to reduce waste, catch problems early, and back up your quality claims with real numbers instead of assumptions.

In other words, real-time data and basic analytics aren’t just about efficiency. They help you show that your process is under control — which matters a lot when you’re dealing with auditors, partners, or markets that are moving toward GMP-style expectations.

5.Compliant Manufacturing (GMP, Traceability, Automated Record-keeping)

Across the cannabis and vape industry, compliance pressure keeps increasing. Regulators and partners alike are paying more attention to what materials touch the oil, how easily equipment can be cleaned, and whether each batch can be traced back through the production process.

That means the right vape cartridge filling machine shouldn’t just be fast — it should also be built with food- or pharma-grade contact surfaces, a hygiene-friendly design, and support for basic record-keeping or integration into a broader tracking system. When your equipment helps you document production, track batches, and demonstrate that only compliant materials touch your product, it becomes part of your risk management strategy, not just a piece of hardware.

So when you’re evaluating options, it’s worth looking beyond “speed + price.” Ask whether the machine will still look like a good decision when inspections get stricter, documentation requirements increase, or you decide to move toward GMP-level operations. The right investment now can save you a lot of headaches later.

What Vape Cartridge Filling Machine to Choose (2025 Recommendations)

Here’s a short, brand-focused way to choose the right vape cartridge filling machine for your operation.

Best for Small Labs & Startups

Manual or entry-level semi-automatic machines

If you’re filling under 500 cartridges or devices a day and still experimenting with strains and formulations, a compact manual or basic semi-auto filler is usually enough. It keeps investment low, gives you flexibility, and lets you validate your products before upgrading to bigger equipment.

Best All-Around Choice for Most Vape Brands

Semi-automatic vape cartridge filling machines

For most growing vape brands, a semi-auto system is the most practical choice. A machine like Longwill’s semi-automatic cartridge and device filler can handle small to medium batches, work with different oil types, and support both cartridges and disposables with the right setup. It’s a solid balance of speed, consistency, and cost.

Best for High-Volume MSOs & Large Manufacturers

Fully automatic cartridge filling lines

When you’re producing tens of thousands of units per week or running OEM/white-label projects, fully automatic equipment makes more sense. Longwill’s automatic filling machines are built for this scale, combining high output with precise dosing and touch-screen control, turning your filling line into a reliable part of your core manufacturing system.

Still Not Sure What Type of Filling Machine Is Right for Your Operation?

If you’re still unsure, evaluate your needs through the following questions:

What is your expected weekly or monthly production volume?

What type of oil are you filling (distillate, live resin, rosin, CBD, etc.)?

Which device formats are you using: 510-thread, CCell, disposables, or a mix?

Do you prioritize maximum speed or maximum precision and quality consistency?

What is your budget, and how fast do you need ROI?

What are your mid- to long-term growth plans? Will you expand production within the next year?

Read more:

Conclusion

No single vape cartridge filling machine is “best” for everyone. The right choice depends on how much you produce, what you fill, which device formats you use, and how quickly you plan to grow. Manual and entry-level semi-auto machines give startups a low-risk way to get moving, semi-automatic systems cover the needs of most scaling brands, and fully automatic lines support high-volume manufacturers that treat filling as core infrastructure.