Live Resin vs Rosin:What's the difference between the two?

In this article, we’ll explore what sets live resin and live rosin apart, and why smart equipment choices can make or break your operation.

What is Live Resin ?

Live resin is a premium cannabis extract renowned for its rich flavor and potent effects. What sets it apart from traditional concentrates is the starting material—fresh cannabis flowers that are frozen immediately after harvest. This cryogenic preservation locks in the plant’s full aromatic and chemical profile before any degradation occurs, particularly the delicate terpenes responsible for flavor and aroma.

To produce live resin, hydrocarbon solvents such as butane or propane are used to extract cannabinoids and terpenes from the frozen plant material. The resulting concentrate is highly aromatic, often sticky or waxy in texture, and valued for delivering what many consider a true-to-plant experience. Because of its terpene-rich nature, live resin is popular among consumers who prioritize flavor and full-spectrum effects.

Core Attributes of Live Resin:

Immediate Fresh-Frozen Source: Made from plants frozen at peak harvest to preserve bioactive compounds.

Solvent-Based Extraction: Requires hydrocarbon solvents to separate oils from plant matter.

Flavor and Aroma Retention: Captures an extensive range of terpenes for enhanced sensory experience.

Thick, Malty Consistency: Usually comes in a saucy, sap-like, or waxy form.

What is Live Rosin ?

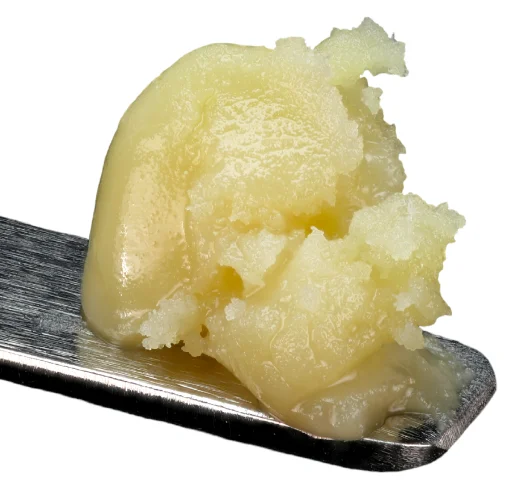

Unlike live resin, live rosin is extracted using a completely solventless technique. It also begins with frozen, uncured cannabis—either flower or hash—but instead of chemicals, heat and pressure are applied to mechanically press out the resin. This approach is favored for its purity and minimal processing, yielding a product that retains the natural complexity of the plant without any solvent residue.

The extraction typically involves using a rosin press, where the frozen material is enclosed in filter bags and placed between heated plates. As pressure is applied, the resin-rich oil is squeezed out and collected. The outcome is a clean, terpene-forward concentrate that appeals to those seeking additive-free cannabis extracts.

Core Attributes of Live Rosin:

Chemical-Free Process: Produced without solvents or additives, making it ideal for health-conscious users.

Mechanical Extraction: Utilizes controlled temperature and pressure to draw out plant oils.

High Fidelity to Plant Profile: Preserves a broad spectrum of cannabinoids and terpenes.

Tacky, Butter-Like Texture: Typically soft, pliable, and easy to manipulate for dabbing or vaping.

Filling Live Resin or Rosin ? Why Your Choice of Oil Filling Machine Is Critical

When working with premium cannabis concentrates like live resin and live rosin, selecting the right oil filling equipment is more than a matter of efficiency—it’s essential for preserving product quality, ensuring dosing accuracy, and minimizing waste.

Both live resin and rosin are known for their thick, sticky consistency, making them far more challenging to handle than standard oils. Their high viscosity limits flow at room temperature, while their heat sensitivity demands precise thermal control during the filling process. Without a properly engineered system, you risk uneven fills, product loss, and even degradation of valuable cannabinoids and terpenes.

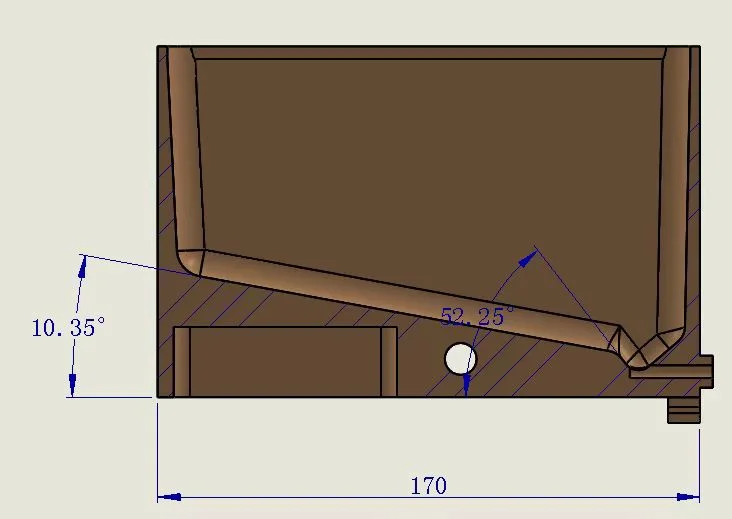

A recent client case illustrates just how critical the right setup can be. The customer was filling live rosin oil, a highly valuable product typically produced in small, irregular batches. Their previous machine came equipped with a 2.5L oil tank and a mild 3–5 degree bottom incline, which required at least 1L of oil to function properly. For rosin, which is often used in limited volumes—such as 300ml, 500ml, or 1L per batch—this setup caused unnecessary waste and operational inefficiencies.

To solve the problem, Longwill delivered a customized solution that addressed three key areas:

Steeper Oil Tank Design for Small Batches

We redesigned the tank with a sharper incline, allowing it to dispense even minimal amounts of oil efficiently. With this upgrade, the client could run small-batch production starting at 300ml—ideal for high-value, limited-quantity concentrates like rosin—without compromising usability or material yield.

Reduced Clean-Air Cycles to Preserve Oil Quality

Most oil filling equipments rely on frequent clean-air purging to clear the lines between fills. However, live rosin must be gently heated to remain flowable, and excessive purging can lead to loss of aroma, potency, and overall product value. Our oil filling machine features a shortened oil path, significantly reducing the need for repeated purging. The result? Less waste, greater efficiency, and better preservation of the product’s chemical integrity.

Low-Temperature Precision Dispensing

Thanks to optimized heat transfer and precise temperature control, the Longwill FM15 automatic cartridge filling machineenabled smooth dispensing at just 40°C—a temperature low enough to protect sensitive terpenes while still ensuring consistent flow. This helped the client avoid overheating and maintained the full spectrum of flavors and effects that make live rosin so desirable.

This real-world case demonstrates an important truth: when it comes to high-value cannabis oils, not all filling machines are up to the task. Purpose-built systems with the right thermal control, volume flexibility, and oil path design don’t just fill your product—they protect its value, preserve its quality, and maximize every drop. For producers working with boutique, small-batch concentrates, this kind of tailored engineering isn’t optional—it’s essential.

Conclusion

As the cannabis concentrate market continues to evolve, so do the expectations for quality, consistency, and efficiency. Whether you're working with live resin or live rosin, your production equipment plays a vital role in maintaining the integrity of your product. From precise temperature control to minimizing waste, the right filling solution is not just a convenience—it’s a competitive edge. At Longwill, we specialize in customized filling machines that are engineered to meet the unique demands of small-batch, high-value cannabis oils. When your concentrate matters, so should your machine.