How to Prevent Leaks in Your Disposable Vape Production

This guide distills what matters most around a cartridge filling machine: select compatible, durable components; engineer and verify seal integrity; meter precisely with headspace control; and keep assemblies aligned.Then protect that good work post-production with upright conditioning, temperature-controlled storage, robust packaging, and targeted leak screening. Use these practices to turn line speed into shippable, leak-free units.

Manufacturing & Design with a Disposable Vape Filling Machine

Use quality components

Select tank bodies and seals that are truly compatible with e-liquids and resist stress cracking. For reservoirs, food-grade PCTG or borosilicate glass stands up to PG/VG blends and aggressive flavorants better than brittle plastics. Metallic wetted parts should be 316L or coated alloys with polished sealing lands (Ra ≤ 0.8 µm). Specify O-rings/gaskets with low compression set (e.g., FKM/FVMQ) and a durometer that achieves seal without over-squeeze. Control molding quality—parting lines, flash, ovality—and require supplier COAs, lot traceability, and incoming checks (dimensions, hardness, swell tests). Many “mystery leaks” trace back to porous tanks or bargain seals that fail after thermal cycles—issues a well-specified disposable vape filling machine will surface quickly during line trials.

Ensure proper seal integrity

Design grooves for the right squeeze and gland geometry, then prove it in assembly with measurable controls. Use poka-yoke to prevent twisted or nicked O-rings, apply only approved lubricants sparingly, and enforce capping/press-fit torque or force windows with calibrated tools. Add in-line presence/placement vision at critical joints and finish with a short pressure or vacuum-decay test to catch gross leaks before pack-out. Define AQL sampling for deeper leak tests by SKU, and log torque/force traces so field returns can be tied to assembly data. Treat sealing as a controlled process on the disposable vape filling machine—not a one-time inspection.

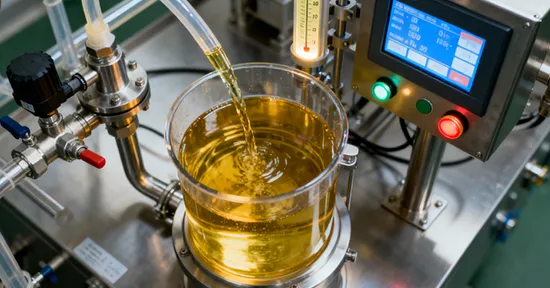

Precisely fill the tank

Run a precision cart filling machine that meters consistently and manages viscosity via temperature-controlled tanks/lines and anti-drip (suck-back) nozzles. De-gas the e-liquid where possible to reduce bubbles, and use a gentle fill profile (soft start/stop) to avoid foaming or disturbed menisci. Leave deliberate headspace—typically 5–10% of volume—so thermal expansion after capping doesn’t over-pressurize the chamber. Finish with the nozzle just below the liquid surface to limit air entrainment, allow a brief settle, then cap within a defined window so each unit equalizes predictably. Tight coordination of dose, temperature, and capping torque prevents “pump-out” and weeping.

Use a higher VG e-liquid (when feasible)

Higher-VG ratios (e.g., 60/40 or 70/30 VG/PG) increase viscosity, reducing wicking through micro-gaps compared with thin, PG-heavy blends. Validate the ratio against your wick/coil design: thicker fluids may need slightly larger wick ports, longer priming, or adjusted power profiles to avoid dry hits—especially in cold conditions where viscosity climbs. Confirm flavor-carrier compatibility and run cold-flow tests so the formulation stays pumpable during filling yet stable in storage, without thinning enough to seep.

Prevent internal misalignment

Many leak paths are simple stack-up errors. Use keyed components, assembly fixtures, and positive stops so chimneys, wicks, tubes, and vents seat one way and to one depth. Employ go/no-go gauges for press-fit heights and airflow bores, and confirm gaskets aren’t pinched at cap closure. A quick vision or laser height check after each critical station will catch skewed inserts before final seal. Document centerlines and tolerance stacks, and empower operators to rework immediately—one misaligned part can create a gap or pressure point no amount of extra torque will cure, regardless of how capable your cartridge filling machine may be.

Post-Production Handling & Storage for Cartridge Filling Machine Output

Store upright

After the cart filling machine completes capping, stage devices upright so gravity keeps e-liquid below the air vents and chimney. This “upright conditioning” also lets headspace pressure settle as temperature changes, which helps prevent seal weeping. Use rigid, partitioned trays to keep units vertical, avoid stacking that can compress gaskets, and hold products for a short soak (about 12–24 hours) so any marginal units show themselves before pack-out.

Temperature-controlled storage

Keep finished goods in a cool, dry area to limit thermal expansion and moisture-related seal fatigue. Stable temperature and moderate RH maintain viscosity and avoid the “hot-room pressurization” that can push liquid through micro-gaps; high humidity can also soften elastomers or wick into fibrous parts. Define a practical temperature/RH band, log it with simple data recorders, rotate FIFO to minimize long dwell times, and use sealed liners or lidded bins to prevent aroma cross-contamination.

Protect during shipping

Design packaging to resist shock, crush, and vibration so assemblies don’t shift and compromise seals—especially for devices filled on a disposable vape filling machine. Form-fit trays or blisters, corner reinforcement, and cartons with sufficient burst strength help products stay upright by design (not just by labels). For air freight or hot lanes, plan for altitude and temperature swings: allow adequate headspace, add thermal buffering (insulated shippers or phase packs as needed), and validate with drop/transport tests that mirror real handling.

Implement quality control checks

Before boxing, test a statistically sound sample per SKU for leaks from each cart filling machine lot. Pair a short vacuum/pressure-decay check with torque audits and a quick meniscus/weight verification to catch gross defects fast. For extra assurance, run brief warm/cool soaks on retains to expose marginal seals, and record results alongside lot, fill temperature, and capping settings for traceability. Set clear AQLs and a containment workflow so any failures trigger root cause and rework before product leaves the building.

Conclusion

Put it all together as standard work: clear specs for parts and seals, validated centerlines on the cartridge filling machine, first-article and in-process checks, and post-production controls (upright soak, temp/RH limits, ship testing, AQL plans).