How Is Live Rosin Made and Why Cartridge Filling Machines Matter

Live rosin has quickly risen to the top of the cannabis concentrate market, celebrated for its solventless extraction, rich terpene profile, and authentic “fresh plant” experience. Unlike many other concentrates, it starts with fresh-frozen cannabis and relies solely on mechanical processes, making it a favorite among purity-focused consumers. However, working with live rosin — especially for vape cartridge production — presents unique challenges due to its thick, sticky texture and sensitivity to heat.

In this guide, we’ll explore exactly what live rosin is made of, how it’s processed, the ideal temperature settings for cartridge filling machines, and whether it’s truly healthier than live resin.

What Is Live Rosin Made Of ?

Live rosin begins with fresh frozen cannabis — entire plants harvested and flash-frozen within mere hours. Rather than undergoing the standard drying and curing steps, the flowers are preserved immediately at sub-zero temperatures. This rapid freeze traps the plant’s natural moisture, locking in its delicate terpene bouquet and active cannabinoids so the aroma, flavor, and effects remain true to the original strain. Skipping the drying phase also shields the plant from oxidation and other degradative changes, keeping its chemical profile as close to “fresh-picked” as possible.

This method sharply contrasts with concentrates made from dried flower. Drying can cause fragile terpenes to dissipate, alter cannabinoid composition, and diminish flavor complexity. By starting with fresh frozen material, producers capture the plant’s full vibrancy — yielding a concentrate that delivers cleaner, brighter flavors and a terpene profile that mirrors the living plant’s character.

How Live Rosin Is Made

Step 1: Harvest and Freeze

The journey begins the moment the cannabis plants are harvested. Instead of following the traditional drying and curing process, the buds are carefully trimmed and frozen solid within just a few hours. This rapid deep-freezing captures the plant’s natural moisture and locks in its delicate aromatic compounds, ensuring cannabinoids and terpenes remain unaltered. By stopping enzymatic activity almost instantly, it prevents the slow breakdown and terpene evaporation that often occur in air-dried flower.

Step 2: Ice Water Hash Extraction

Once frozen, the cannabis is gently agitated in ice-cold water. The frigid temperatures make the resin glands, or trichomes, brittle enough to snap away from the plant material without damaging their structure. This method uses no solvents, preserving the plant’s original chemistry while minimizing impurities — resulting in a cleaner, more true-to-strain starting material.

Step 3: Filtration and Collection

The trichome-rich slurry is poured through a series of fine mesh filters or “bubble bags,” each with a specific micron size. These screens separate resin heads by grade, with the highest-quality trichomes reserved for pressing into live rosin. The overall quality of the final concentrate is closely tied to the purity, size, and integrity of the trichomes collected at this stage.

Step 4: Cold Room Drying

The freshly collected hash is spread out in thin layers within a cool, low-humidity environment. Over several days, excess moisture evaporates without exposing the material to damaging heat. Keeping temperatures low helps prevent oxidation and preserves volatile terpenes, ensuring the hash maintains its aroma, potency, and chemical stability until pressing.

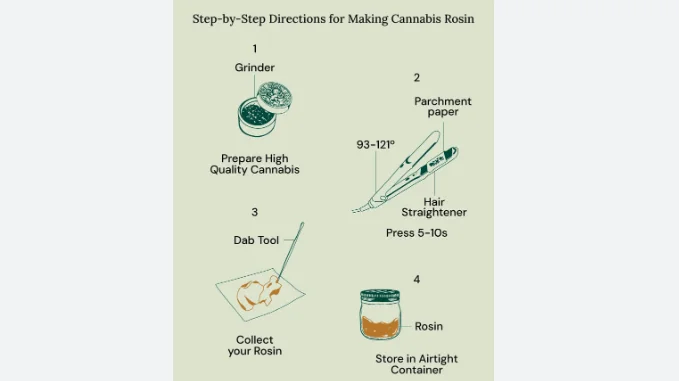

Step 5: Rosin Pressing

When the hash reaches its ideal dryness, it’s placed between parchment paper and pressed under carefully controlled heat and high pressure. This process squeezes out a rich, golden oil without introducing chemical solvents. Fine-tuning temperature and pressure is key — too much heat can burn off terpenes, while too little pressure may leave valuable oil behind. The result is a potent, flavorful concentrate that stays true to the essence of the living plant.

Step 6: Preparation for Packaging

Once pressed, live rosin can range in texture from a light, whipped consistency to a dense, stable form. For vape cartridge production, the concentrate needs to be conditioned so it fills smoothly without causing clogs or trapping air. This is where using a cartridge filling machine with precise and consistent temperature control becomes essential for maintaining product quality.

For most batches, keeping the rosin between 65°C and 75°C (149°F–167°F) offers the ideal balance — warm enough for steady, even dispensing, yet gentle enough to protect the volatile terpenes that define its aroma and flavor. Strains with especially high terpene content, or those processed as “cold cure” rosin, may benefit from slightly lower settings around 60°C (140°F) to preserve their more delicate flavor notes.

High-end cartridge filling machines are designed to manage heat at multiple points in the process. The reservoir is gradually warmed to the target temperature to avoid scorching and terpene loss. Heated transfer lines maintain the rosin’s viscosity as it moves toward the dispenser, preventing thickening mid-flow. At the nozzle, carefully controlled warmth ensures the concentrate doesn’t cool and harden before entering the cartridge — resulting in precise, drip-free fills.

By managing temperature with this level of accuracy from start to finish, producers can adapt to variations in batch texture and cannabinoid profile, reduce waste, and consistently deliver vape cartridges that reflect the same quality, flavor, and character as freshly pressed live rosin.

Cartridge Filling Machine: Best Temperature Settings for Live Rosin

Live rosin is prized for its potency, rich terpene profile, and solventless extraction process. Yet, its thick, sticky, honey-like texture makes it one of the most challenging concentrates to package — especially in vape cartridges. At this stage, the cbd cartridge filling machine is more than just a tool; it’s essential for smooth, consistent, and high-quality fills. Among all factors, temperature control is the key. Too cool, and the rosin thickens, slowing production and causing uneven fills. Too hot, and delicate terpenes and cannabinoids can be lost, affecting flavor, aroma, and effects.

Finding the Ideal Temperature Range

Most experienced operators keep live rosin between 65°C and 75°C (149°F–167°F) when using a cbd cartridge filling machine. This range is warm enough for steady flow yet gentle enough to protect terpene quality. For high-terpene strains or sensitive “cold cure” batches, slightly cooler settings around 60°C (140°F) can help preserve subtle flavors and aromatic complexity.

How CBD Cartridge Filling Machines Maintain Optimal Heat

Modern cbd cartridge filling machines designed for thick extracts like live rosin often use multi-zone heating systems to maintain the right viscosity throughout the process:

Reservoir Pre-Heating – Gradually warms bulk rosin to target temperature, avoiding sudden heat spikes that can damage terpenes or cause burnt flavors.

Heated Transfer Lines – Keep rosin flowing smoothly to the dispensing head, preventing mid-process thickening.

Temperature-Controlled Nozzles – Maintain ideal warmth at the tip to prevent clogs and ensure clean, drip-free filling.

Adjusting for Different Rosin Textures

Live rosin isn’t uniform in texture. Fresh “cold cure” batches tend to be soft and workable, while aged or “grease” rosin can be dense and resistant. A cbd cartridge filling machine with precise, stage-by-stage temperature control lets operators fine-tune heat for each batch, ensuring smooth flow without overheating sensitive compounds.

Why Temperature Precision Defines Quality

Accurate temperature control ensures each cartridge is filled evenly, without air pockets, scorching, or terpene loss. For premium brands, a well-calibrated cbd cartridge filling machine doesn’t just improve efficiency — it safeguards the authentic flavor and potency of fresh live rosin, delivering a clean, flavorful vaping experience that stands out in the market.

Is Live Rosin Healthier Than Live Resin?

Extraction Method: Mechanical Press vs. Solvent-Based Process

Live rosin is obtained through a completely mechanical extraction process. Fresh-frozen cannabis is gently washed in ice water to separate trichome heads, which are then pressed under controlled heat and pressure to release the resin. Since no chemical agents are involved, cannabinoids and terpenes remain as close to their original form as possible.

Live resin, on the other hand, uses hydrocarbon solvents like butane or propane to dissolve and extract the plant’s active compounds. While this method is fast and highly efficient at retaining aroma and potency, it requires precise purging to ensure that no solvent remains in the final concentrate.

Chemical Residue Risk & Safety

The solventless nature of live rosin means it carries virtually zero risk of chemical contamination, making it a preferred option for those who value purity and natural processing. It also avoids the regulatory requirements associated with solvent-based concentrates. For live resin, when extracted and purged correctly, residual hydrocarbons are typically well below safety thresholds — but mistakes in handling or equipment calibration can leave behind traces. This makes it essential to buy from trusted producers who provide transparent, lab-tested results.

Flavor & Full-Spectrum Experience

Many enthusiasts praise live rosin for delivering an authentic flavor profile, as the absence of chemical interaction helps preserve the natural terpene composition of the plant. The result is a smooth, clean inhale with an effect spectrum that closely matches the original flower. Live resin also offers a rich terpene experience thanks to flash-freezing techniques, yet some subtle differences in aroma and taste can occur due to the solvent extraction stage. While both can be flavorful and potent, rosin’s solvent-free origin often appeals to those seeking the most unaltered, true-to-plant experience.

Conclusion

Whether you’re a cannabis enthusiast looking for the cleanest, most natural concentrate, or a producer aiming to deliver premium vape cartridges, understanding the nuances of live rosin is essential. From its fresh-frozen origins to solventless extraction, every step preserves the plant’s full-spectrum flavor and potency