What Is Live Rosin——How Cartridge Filling Machines Handle It?

Live rosin has quickly become one of the most sought-after cannabis concentrates, valued for its solvent-free purity, rich terpene profile, and potent cannabinoid content. Unlike traditional extracts, it captures the plant’s essence through a careful mechanical process that avoids chemical solvents altogether.

This article is designed to help producers understand the unique challenges of live rosin filling and packaging. We’ll explore how concentration and terpene levels influence viscosity, why proper temperature management is critical, and what types of filling machines are best suited for different extract profiles.

What Is Live Rosin

Live rosin is considered one of the most refined cannabis concentrates, appreciated for its strength, purity, and solvent-free origin. Unlike extracts that rely on hydrocarbons or CO₂, this concentrate is obtained through a mechanical press, where measured heat and pressure draw out the plant’s resin. Its defining element is the use of fresh-frozen cannabis, preserved right after harvest to safeguard the full profile of cannabinoids and terpenes.

The outcome is a product with notable chemical richness, typically measuring 60–80% THC alongside 5–15% terpene content. This balance produces an extract that mirrors the living plant itself, offering pronounced flavor, layered scent notes, and a smooth experience.

A key distinction of live rosin lies in its inconsistent texture. Depending on cannabinoid strength and terpene ratio, it may take the form of a thin, syrup-like liquid, a whipped, creamy batter, or a denser jam-like material. Such variations not only influence how consumers enjoy it but also present processing and packaging challenges.

For large-scale producers, these differences mean that general-purpose cartridge filling machines are often inadequate. Instead, specialized systems are required—equipment designed to handle sticky materials while applying precise, low-temperature control. This protects fragile terpenes and ensures the final product retains the premium qualities that set live rosin apart.

How Live Rosin Is Made

Live rosin is created through a solventless extraction process designed to preserve the plant’s natural profile. Rather than using chemical solvents, it relies on cold storage, water-assisted separation, and mechanical force:

Fresh-Frozen Cannabis – Right after harvest, cannabis is rapidly frozen to lock in cannabinoids and terpenes before any degradation occurs.

Ice Water Separation – The frozen material is gently mixed in ice water, causing resin glands (trichomes) to break free while most plant matter remains behind.

Rosin Press (Heat + Pressure) – These trichomes are then pressed under carefully controlled pressure and temperature, producing the extract known as live rosin.

Because no hydrocarbons are used, the process avoids residual contaminants and yields a broad-spectrum concentrate that carries both strength and aromatic complexity. Still, the outcome can vary in viscosity and heat sensitivity, making it challenging to handle in large-scale production. These characteristics must be managed with precision, particularly when moving toward automated filling and packaging solutions.

Why Concentration Matters for Cartridges Filling Machine

Live rosin varies significantly in behavior during processing, and its THC level together with terpene content largely dictate its viscosity. This directly impacts how smoothly the material can be dispensed through a cartridges filling machine:

Low to Mid Potency (60–70% THC): The concentrate stays relatively fluid, making it suitable for filling with standard heated units that require only moderate temperature support.

Medium to High Potency (70–80% THC): As viscosity increases, precise thermal regulation becomes essential to keep the material flowing while safeguarding terpene integrity.

High Potency + High Terpene (75–85% THC, 10%+ terpenes): Dense, sticky, and extremely heat-sensitive. These batches demand advanced systems equipped with multi-zone heating and gentle pumping mechanisms to prevent product damage.

For producers, the real challenge lies in maintaining optimal thermal balance. Insufficient heat can cause clogging and inconsistent dosing, while excessive heat degrades volatile terpenes—the compounds responsible for flavor and aroma. By matching the concentrate’s characteristics with the right cartridges filling machine, manufacturers can achieve both reliable throughput and preservation of live rosin’s premium quality.

Cartridges Oil Filling Machine Options for Live Rosin

Since live rosin’s consistency shifts with both potency and terpene levels, the type of filling machine selected has a direct impact on production efficiency, consistency, and overall product quality. In practice, producers generally turn to three main categories of equipment, each designed to handle specific extract profiles.

Semi-Automatic Filling Machines

Semi-automatic systems are best suited for concentrates with moderate strength, typically in the 60–70% THC range. Operated manually or with a simple foot pedal, they give operators hands-on control without the complexity of full automation. These machines usually rely on basic heating elements set around 40–50 °C, which is sufficient to reduce viscosity and ensure smooth dispensing while keeping heat exposure low. For labs focusing on pilot runs, artisanal batches, or smaller-scale projects, semi-automatic fillers provide an affordable and flexible solution where adaptability matters more than speed.

Heated Automatic Cartridge Fillers

For extracts in the 70–80% THC range, heated automatic fillers strike a balance between precision and throughput. They feature advanced thermal management systems that typically hold product temperatures between 50 and 70 °C, keeping the rosin fluid throughout the process. Their pumps are designed to minimize clogging, while dosing systems deliver highly consistent fills for cartridges, syringes, or disposable pens. This type of machine is a strong fit for companies moving into commercial-scale production, as it ensures reliability and repeatability without diminishing the rosin’s flavor or aromatic complexity.

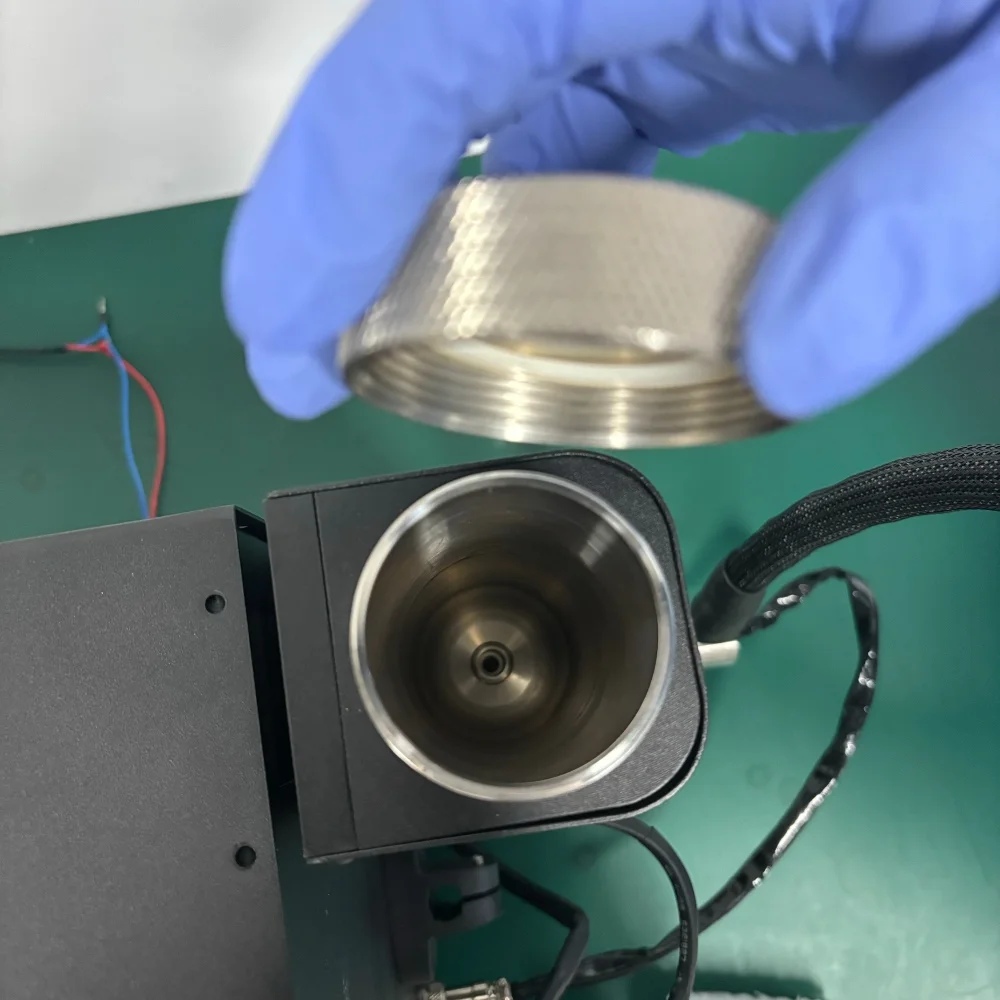

Advanced Rosin Filling & Capping Lines

High-potency rosin with elevated terpene content—often 75–85% THC with more than 10% terpenes—demands specialized equipment. Advanced filling and capping lines use multi-zone heating with individually controlled sections to maintain stable, safe temperatures across the pipeline. Low-shear pumping technology helps safeguard delicate terpenes, while integrated capping and sealing modules transform the process into a streamlined, continuous workflow. These systems are designed for OEM and ODM manufacturers who require large-scale production capabilities while maintaining consistency, protecting product integrity, and maximizing efficiency.

Heating Guidelines for Rosin Filling

Temperature management is just as critical as machine selection when it comes to filling rosin. Proper heat control ensures the material flows smoothly without damaging its active compounds or altering flavor. Lower-potency extracts in the 60–70% THC range usually perform well at 40–50 °C, which reduces thickness while preserving taste. For medium-strength rosin at 70–80% THC, temperatures between 50 and 70 °C are recommended, providing stable flow and protecting aromatic compounds. High-potency concentrates in the 75–85% THC range benefit most from 45–55 °C, ideally with segmented heating zones to prevent uneven hot spots that could harm terpenes.

Conclusion

As consumer demand for solventless extracts continues to rise, producers face growing pressure to scale live rosin production without compromising its delicate profile. From small-batch semi-automatic fillers to fully integrated rosin filling and capping lines, the choice of equipment directly shapes efficiency, consistency, and overall product quality.