How Cartridge Filling Machines Can Transform Your Business

Looking to turn inconsistent manual work into predictable output? A cartridge filling machine does exactly that—tight cycle times, fast changeovers, and built-in checks that raise OEE while easing operator load. In the sections below,you’ll see how a cartridge filling machine boosts speed, lowers unit cost, improves product consistency, and gives your business the agility to grow.

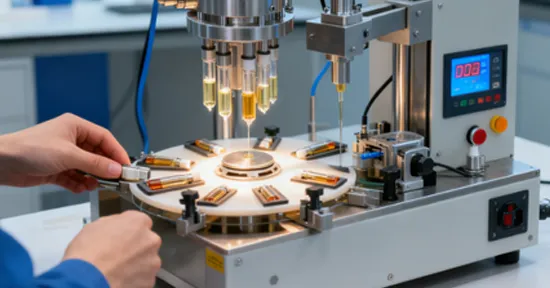

Increased efficiency and speed with a cartridge filling machine

Cartridge filling machines turn stop–start manual work into a stable, repeatable flow. Servo-metered dosing, heated fluid paths, and drip-free nozzles keep cycle time tight, so nameplate speed becomes steady output instead of peaks and valleys. Inline checks (weighing/vision) let you run faster without losing control, while digital recipes and centerlines cut changeovers to minutes. Beyond raw speed, stabilizing viscosity and nozzle motion trims micro-stops, protecting the Performance leg of OEE and smoothing cadence over long shifts for a well-specified cartridge filling machine.

As you scale, multi-head configurations and indexed fixtures keep utilization high with less operator fatigue. Small tweaks compound: a cleaner withdrawal curve, pre-heated cartridges for viscous oils, or a smarter reject routine can add hundreds of units per shift. Tie pace to a takt target and surface constraints with a simple board; when the cartridge filling machine is the bottleneck, even a 0.1–0.2 s reduction per shot yields thousands of extra units weekly. Real-time OEE dashboards help you catch drift early—before it turns into lost hours.

Cost reduction with a cart filling machine

Automation lowers unit cost on both variable and fixed fronts. Labor minutes per cartridge fall as the system handles dosing, capping, and checks; at the same time, utilities, depreciation, and supervision are spread over a larger base of good output. Disposable tubing and nozzle kits shorten cleaning and validation, cutting chemical spend and changeover downtime. Higher first-pass yield reduces scrap and rework, protecting material budgets and schedule integrity on the cart filling machine.

Push CPU down further with standardized wear parts, predictive counters (pump cycles, seal life), and planned spares to avoid emergency stops and premium freight. Track energy per good unit: right-sized heaters, insulated zones, vacuum duty-cycling, and idle/eco modes trim consumption. Use a simple cost bridge (before/after) across labor, consumables, utilities, depreciation, and scrap so each kaizen shows a measured payback. Even a 1–2% cut in average overfill converts directly into material savings without touching cycle time.

Enhanced product quality and consistency from a vape cartridge filling machine

A modern vape cartridge filling machine functions as a precision dosing platform. Closed-loop metering holds volume to tight tolerances, temperature control stabilizes viscosity, and suck-back tips prevent stringing and drips. Optional vacuum de-aeration and nitrogen purging curb bubbles and oxidation, while torque/press monitoring secures seal integrity. With inline verification—check-weighing or meniscus vision—you ship uniform fills that reduce returns and strengthen brand trust.

Quality systems travel with the hardware: digital traceability (batch IDs, timestamps, parameters), audit-friendly logs, and SPC on critical features detect drift before it becomes scrap. Define clear acceptance limits and escalation paths; when Cp/Cpk trends slip, operators adjust once instead of chasing defects downstream. Calibrated test packs and a tight first-article routine prevent “golden unit creep,” and recipe versioning ensures the same result across shifts, lines, and sites.

Business flexibility and growth powered by a cartridge filling machine

Markets move fast—new SKUs, package styles, regulations—and the right vape cartridge filling machine keeps up. Modular fixtures and quick-change nozzles support multiple cartridge sizes and fill volumes on one frame, while digital recipes synchronize parameters across products for rapid pilots and seasonal runs without new CAPEX. As demand grows, you can add heads, bolt on capping/labeling/inspection modules, or extend shifts—scaling capacity without redesigning the line.

That operational agility turns into commercial advantage. Shorter changeovers and cleaner ramp-ups let sales quote tighter lead times; compliance needs (materials of construction, data retention) are handled via software and documentation rather than hardware swaps. Standardized centerlines, spares, and training make it easy to replicate a proven cell at another site—same setup, same results—so growth feels like copy-and-paste, not reinvention.

Conclusion

Adopting the right cartridge filling machine pays off on four fronts: more throughput, lower CPU, tighter quality, and easier scaling. Start with quick wins—stabilize viscosity and nozzle motion, shorten changeovers, and track energy per good unit—then layer in recipes, multi-head capacity, and inline verification. The result is a production cell that ships more, wastes less, and adapts faster as your SKUs and volumes evolve.