Ceramic vs. Peristaltic: Best Pump for a Disposable Vape Filling Machine

When setting up a disposable vape filling machine, one of the most important decisions you’ll make is choosing the right pump. The type of pump you select directly affects hygiene, dosing accuracy, and overall product quality. This article is designed to compare peristaltic pumps and ceramic pumps in the context of disposable vape filling machines, explaining how each works, outlining their strengths and weaknesses, and helping you decide which option best supports efficient, reliable, and scalable vape production.

Understanding Pump Options for a Disposable Vape Filling Machine

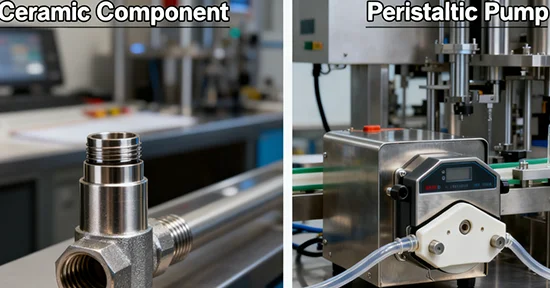

Peristaltic Pump Basics

If you’re operating a disposable vape filling machine, the peristaltic pump is often the first option worth considering. This type of pump works by gently squeezing and releasing a flexible tube, creating a steady flow that moves the liquid forward. Because the e-liquid only ever touches the tubing, and not the inner parts of the pump, the risk of contamination is practically eliminated. For anyone handling vape cartridges, that means cleaner production and greater peace of mind. Another benefit is the simplicity of upkeep—when the tubing wears out, you just replace it. This quick swap minimizes downtime, making your filling process more efficient and reliable.

Ceramic Pump Basics

Ceramic pumps operate differently: they rely on a precision piston or plunger made from high-grade ceramic that moves inside a chamber to push liquid through. They are well-regarded in industries like pharmaceuticals and chemical manufacturing for their durability, resistance to wear, and ability to handle high temperatures or corrosive substances. However, if you are filling vape cartridges with standard e-liquids on a disposable vape filling machine, ceramic pumps often feel like overkill. Vape e-liquids are usually low in viscosity and sensitive to contamination, and the ceramic pump’s design can make cleaning more complex. In practice, this means you might spend more time maintaining the system than actually running it.

Why Peristaltic Pumps Are Ideal for Vape Cartridge Filling Machines

Hygiene & Zero Contamination

When filling cartridges with a vape cartridge filling machine, hygiene is one of the top priorities. With a peristaltic pump, the e-liquid flows only through the flexible pump tube and never touches the machine’s internal components. This closed system greatly lowers the risk of cross-contamination between batches. For manufacturers producing thousands of disposable units daily, the ability to replace a sterile tube in just a couple of minutes means cleaner operations and reduced downtime.

High Precision in Dosing

Accuracy is essential for disposable vapes, which are typically filled with 0.5 mL or 1.0 mL of e-liquid. Peristaltic pumps are well-known for their dosing precision, with many systems offering ±1% accuracy. Integrated into a vape cartridge filling machine, this precision ensures every cartridge is filled consistently, which improves quality control, enhances customer satisfaction, and reduces costly product waste during large-scale production.

Gentle Handling for Vape Liquids

Many vape oils and distillates contain delicate compounds such as terpenes that can be damaged by harsh mechanical stress. The smooth, squeezing action of a peristaltic pump moves liquid gently, minimizing shear forces that could degrade flavor or potency. This careful handling helps ensure that what consumers taste and experience is exactly the high-quality product you intended.

Perfect for Low-Viscosity Liquids

Most e-liquids used in disposable vapes have a relatively low viscosity—typically between 10 and 100 cP—which makes them a natural fit for peristaltic pumps. These pumps are engineered to handle thinner liquids efficiently, providing smooth, bubble-free filling. By choosing a peristaltic pump for your disposable vape filling machine, you’re matching the equipment to the natural flow properties of vape oil, resulting in a faster, cleaner, and more reliable filling process.

When Ceramic Pumps Might Be Considered for a Disposable Vape Filling Machine

Ceramic pumps are not usually the first choice for a disposable vape filling machine, but there are rare circumstances where they may prove useful. One such case is when an e-liquid formulation contains corrosive ingredients—something almost never seen in vaping, but more common in chemical or pharmaceutical production. In these conditions, the excellent chemical resistance of ceramic plungers can help extend the pump’s service life. Data from industrial use shows that ceramic components can endure over 10 million cycles with minimal wear, making them extremely durable under tough operating conditions.

Another scenario is high-temperature filling. Ceramic pumps can operate reliably at temperatures above 150 °C, far beyond what peristaltic tubing can safely handle. While standard vape oils are typically processed below 60 °C on a disposable vape filling machine, this extra tolerance demonstrates the robustness of ceramic technology. These situations remain exceptions rather than the norm, but they highlight how ceramic pumps may still be relevant in niche applications where resistance to heat and corrosion is critical.

Limitations of Ceramic Pumps in Vape Cartridge Filling Machines

Not Contamination-Free

Unlike peristaltic pumps, ceramic systems push the liquid directly through the pump chamber and across ceramic components. For vape oils filled with a vape cartridge filling machine, this design introduces hygiene risks, since residues can build up inside the mechanism and increase the chance of cross-contamination between production batches. In an industry where purity and consistency are non-negotiable, this limitation is hard to ignore.

Complex Maintenance

Ceramic pumps are designed with more intricate moving parts, which makes routine upkeep more demanding. Cleaning or sterilizing typically requires disassembly and careful handling, extending the time needed between runs. By contrast, a peristaltic pump on a vape cartridge filling machine can be reset quickly by replacing the tubing—often in just a few minutes. For manufacturers producing high volumes, the extra downtime and higher maintenance costs of ceramic systems can make them less practical.

Shear Sensitivity

While ceramic pumps are appreciated for their long service life, their piston-driven action applies greater mechanical stress to the liquid. For e-liquids rich in terpenes or other delicate compounds, this shear can affect stability and subtly alter flavor. A peristaltic pump integrated into a vape cartridge filling machine moves liquid with a gentle rolling action, helping preserve both chemical integrity and sensory quality. This allows producers to deliver a consistent vaping experience that aligns with consumer expectations.

Conclusion

In most cases, the peristaltic pump is the clear winner for a disposable vape filling machine thanks to its contamination-free design, precise dosing, gentle handling, and compatibility with low-viscosity vape oils.