Cartridge Filling Equipments and Oil Pumps Key Processes Explained

In today’s fast-paced manufacturing environment, efficiency, precision, and reliability are no longer optional—they are essential. This is especially true in industries that handle oils, lubricants, food products, or pharmaceuticals, where even small deviations in volume or quality can affect costs and customer trust. A cartridge filling equipment addresses these challenges by combining advanced automation with precise control mechanisms. From container feeding and indexing to oil pump regulation and post-filling automation, the modern oil cartridge filling machine is designed to streamline operations, reduce waste, and ensure every container meets the highest standards of consistency.

This article explores the core automatic processes of cartridge filling equipment and oil pumps, highlighting how they function together and what benefits they bring to your production line.

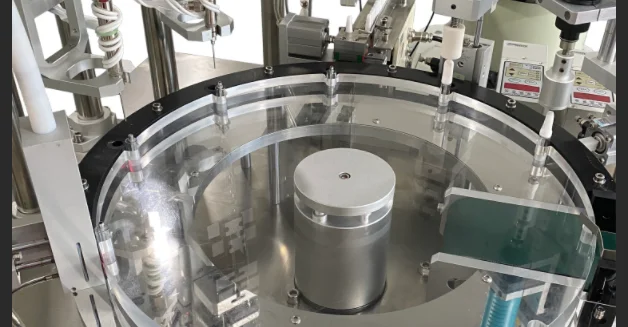

Automatic Processes of an Oil Cartridge Filling Machine

Container Feeding and Indexing

When you use an oil cartridge filling machine, the first step begins as empty bottles or cans are carried into the filling area on a conveyor system. At this point, sensors detect and count each container to make sure the line flows without interruption. An indexing mechanism—such as a timing screw or a gating device—positions the containers directly under the filling nozzles. This accuracy ensures your production line runs efficiently, while the filling machine consistently prepares each container for the next stage.

Filling Cycle

Once the containers are in place, the oil filling machine automatically triggers the filling process through its PLC or electronic control unit. Depending on the type of filler you are working with, the machine may use piston technology, a vacuum system, or pump-based mechanisms to dispense the oil. In many modern machines, the nozzles move downward into the container for bottom-up filling, which helps you avoid foaming or splashing. As soon as the programmed volume is dispensed, the valves close immediately, guaranteeing that every container is filled with consistent accuracy.

Container Outfeed

After the filling is done, the indexing system releases the containers, allowing them to travel along the conveyor belt toward the next operation. For your production line, this step creates a smooth transition from the automatic oil filling machine to processes like capping, labeling, or sealing. By keeping this movement seamless, you reduce downtime and maintain a steady workflow, which is critical for high-volume production.

Post-Filling Automation

An oil cartridge filling machine does much more than just dispense oil—it also integrates with post-filling automation to streamline the rest of your operation. After containers are filled, automatic capping units secure the lids tightly, while labeling machines apply product information with precision. Quality control systems, such as checkweighers and advanced sensors, inspect every container to detect inconsistencies, automatically removing any defective items. Finally, the containers are packaged, sealed, and prepared for shipping without requiring manual intervention. This end-to-end automation is what makes an automatic oil filling machine such a valuable investment for businesses that need both speed and reliability in their operations.

Automatic Processes of Oil Pumps in Cartridge Filling Equipment

The Role of Oil Pumps in an Cartridge Filling Equipment

Within an automatic oil cartridge filling machine, the pump functions as the central component that transfers oil from the storage tank to the filling nozzles. Its primary purpose is to deliver a steady, consistent, and well-regulated flow of liquid. If the pump is unreliable, even the most advanced filling machine will struggle to achieve accuracy or maintain continuous production. For this reason, pumps are often regarded as the core of every oil filling machine, ensuring that precision and efficiency are possible on a large scale.

Positive Displacement Pumps for Cartridge Filling Equipment

Most modern oil cartridge filling machines rely on positive displacement pumps because they can manage oils of different viscosities while still providing precise dosing. Two of the most widely used designs are piston pumps and gear pumps:

Piston pump: The piston retracts to draw oil into a cylinder and then pushes forward to discharge it, supplying a fixed volume with each stroke.

Gear pump: Interlocking gears capture and transport oil from the inlet to the outlet as they rotate, making them suitable for light to heavy oils.

By incorporating these pumps, a cartridge filling equipment can achieve highly accurate fills, even with challenging product characteristics.

Advanced Pump Control Methods in Oil Cartridge Filling Machines

To maximize performance, today’s filling machines integrate intelligent pump control systems. Depending on the configuration, you may encounter:

Time-based filling: The pump operates for a programmed duration to deliver the target amount of oil.

Pulse-based filling: The system tracks gear rotations or internal pump movements, dispensing a set volume after a defined number of pulses.

Servo-driven pumps: In many premium automatic oil filling machines, servo motors drive the pumps, offering precise adjustments in speed and displacement. This technology allows for repeatable accuracy, making it ideal for high-volume production where consistency is critical.

Pressure Regulation in Oil Cartridge Filling Machines

Another essential safeguard in an oil filling machine is its pressure regulation system. A pressure relief valve automatically activates if internal pressure rises above safe limits, releasing excess force before closing again. This mechanism not only protects the equipment but also preserves product quality, enabling the cartridge filling equipment to operate safely and reliably over long production runs.

Key Benefits of Using a Cartridge Filling Equipment

Boosting Efficiency and Production Capacity

When you adopt a cartridge filling equipment, your production line can achieve far greater output compared to manual methods. Containers move seamlessly from infeed to filling and downstream processes with minimal downtime. A well-designed filling machine is capable of handling hundreds of containers per hour with reliable accuracy, allowing you to expand capacity without compromising product quality.

Precision Filling for Less Waste

Another major benefit of an oil filling machine is its ability to maintain consistent fill volumes across every container. Whether powered by a piston, vacuum, or pump system, the equipment is engineered to minimize variation and eliminate overfills. This precision reduces unnecessary product loss, saves costs on raw materials, and ensures customers receive the correct amount every time. In industries with tight profit margins, such accuracy provides a measurable competitive advantage.

Reduced Labor Dependence and Lower Costs

By automating your filling operations, you also reduce the need for excessive manual labor. Instead of multiple operators handling repetitive tasks, an automatic oil filling machine requires only minimal oversight. This not only lowers staffing costs but also reduces physical strain on workers. Freed from repetitive duties, employees can focus on quality assurance, process optimization, and other tasks that add more value to your operation.

Enhanced Hygiene and Consistent Quality

For industries such as food processing, pharmaceuticals, or cosmetics, sanitation and consistency are top priorities. A modern oil filling machine is typically built with hygienic design principles, using food-grade or pharmaceutical-grade materials that comply with strict standards. Since the process involves minimal human contact, the risk of contamination is reduced significantly. At the same time, automation ensures that each container is filled to the same high standard, strengthening both product reliability and brand trust.

Conclusion

Whether your goal is to scale up production, reduce operational costs, or improve product safety, a cartridge filling equipment delivers measurable value across every stage of the process. With intelligent pump systems, precise filling cycles, and seamless integration into packaging lines, these machines ensure both speed and reliability.