Best Semi-Automatic Cartridge Filler Machine 2025 – Ideal for Small and Medium Manufacturers

As the demand for CBD and vape products continues to grow, manufacturers are increasingly turning to semi-automatic cartridge filler machines to streamline production, ensure precision, and maintain consistent quality. From small startups to medium-sized operations, choosing the right semi-automatic cartridge filling equipment can make a significant difference in efficiency, cost, and product reliability.

In this guide, we compare the top semi-automatic cartridge fillers for 2025, highlighting their key features, performance, and suitability for different production needs.

Comparison Table of Top Semi-Automatic Cartridge Fillers for 2025

Feature | Longwill Semi-Auto | HotShot™ Pro (CoolJarz) | Cart Shooter (Viking Lab Supply) | SHARRB (USA Lab) | Jet Fueler (Vape-Jet) |

Ideal For | Small to medium manufacturers | Small to medium manufacturers | Startups and small operations | Very small-scale & R&D labs | Growing medium-sized manufacturers |

Max Speed | Moderate batch sizes | 16,000/shift | 1,800/hour | Single units | 14,000/shift |

Accuracy | ±0.01 mL | High, short oil path | ±1% | High, single units | ±0.01 mL |

Reservoir | Moderate size | 1,000 mL | 1,200 mL | 25–50 mL | 1,000 mL |

Key Features | User-friendly, versatile, durable | Short oil path, one-touch cleaning | Foot pedal, versatile | Heated syringe, precise dosing | PID heat control, nitrogen-pressurized |

Best For | Reliable all-around performance | High speed + small footprint | Budget-friendly automation | Small, precise batches | Prioritizing quality & consistency |

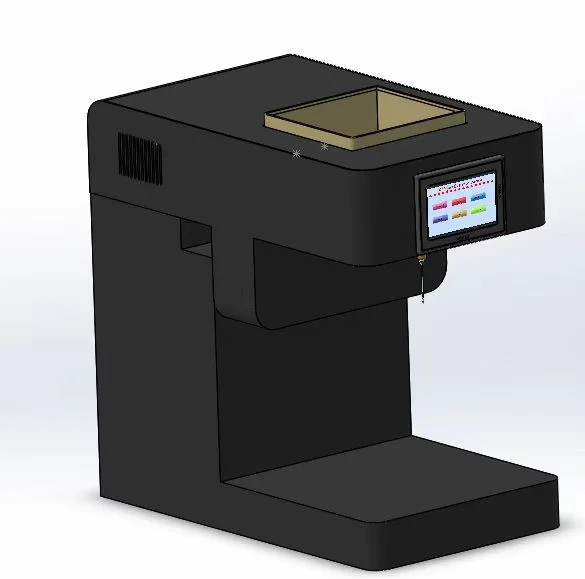

Longwill Semi-Auto Cartridge Filling Machine

The Longwill Semi-Auto CBD Cartridge Filling Machine (Model: YC-300) is a high-performance solution designed for small to medium-sized manufacturers who require precision, efficiency, and flexibility. This semi-automatic cartridge filler enables producers to maintain consistent product quality while adapting to a variety of production needs. It is an ideal choice for businesses that want to scale operations without sacrificing accuracy or reliability.

Production Efficiency: Optimized for Small to Medium Batch Output

With the ability to fill 800 to 1,500 cartridges per hour, the YC-300 stands out as a reliable semi-automatic cartridge filler for small and medium production lines. Its steady output helps you meet growing consumer demand while avoiding overloading your team. By streamlining the filling process, this semi-automatic cartridge filling equipment minimizes bottlenecks and optimizes workflow, allowing you to increase overall productivity. For manufacturers planning gradual growth, it provides a dependable, high-throughput solution that keeps operations competitive.

Precision Filling: Consistent Dosing Every Time

Consistency is key in the vape and CBD industry, and the YC-300 excels as a semi-automatic cartridge filler machine. Supporting filling volumes from 0.2 mL to 7 mL with an adjustment precision of 0.1 mL, it ensures each cartridge receives the exact amount of product. This level of accuracy reduces waste, maintains uniformity across batches, and helps manufacturers meet regulatory standards. Whether filling high-viscosity concentrates like Delta 9, Delta 8, HHC, THCO, or lighter CBD oils, this semi-automatic cartridge filling equipment delivers reliable results that protect your brand reputation.

Easy Maintenance: Short Oil Path Design

The semi-automatic cartridge filler is designed for simple cleaning and minimal maintenance. Its short oil path reduces residual product and lowers the risk of cross-contamination, which is critical when switching between batches or products. This thoughtful design reduces downtime and labor costs, keeping your production line running smoothly while preserving product quality and safety.

User-Friendly Operation: Intuitive and Flexible

This semi-automatic cartridge filler machine is highly intuitive, featuring a touchscreen interface for precise control and a foot pedal option for hands-free operation. Operators with minimal technical experience can quickly learn to use the machine, making it suitable for diverse production environments—from compact labs to more extensive production setups. The combination of intuitive controls and flexible operation helps reduce errors and improve overall efficiency.

High Stability: Reliable Continuous Production

Built for extended operation, the YC-300 combines stepper motors, guide rail systems, and Longwill’s intelligent filling technology to ensure stable performance over long production runs. This stability minimizes mechanical errors and downtime, allowing manufacturers to meet tight deadlines and scale production without compromising quality.

Versatile Compatibility: Handles Various Oils and Cartridges

The semi-automatic cartridge filler is a highly adaptable semi-automatic cartridge filler. It supports a wide range of cartridge types, including standard 510 cartridges and disposable vapes, and is capable of filling both thick concentrates and low-viscosity CBD oils. This flexibility allows producers to switch between products or experiment with new formulations without investing in additional equipment, saving both space and costs.

Durable Construction: Built to Last

Durability is a core feature of this semi-automatic cartridge filling equipment. Made from medical-grade stainless steel that meets FDA standards, all parts in contact with the oil are safe, corrosion-resistant, and long-lasting. The robust construction ensures minimal maintenance, a long service life, and consistent performance, making it a cost-effective solution for growing manufacturers.

Application Scenarios: Perfect for Small and Medium Manufacturers

The Longwill semi-automatic cartridge filler is well-suited for small to medium-sized CBD and vape cartridge producers who need a reliable, precise, and efficient semi-automatic cartridge filler. It serves startups launching new product lines as well as established brands looking to expand production capacity. Combining speed, accuracy, and versatility, the YC-300 empowers manufacturers to scale efficiently, maintain product consistency, and stay competitive in today’s fast-growing market.

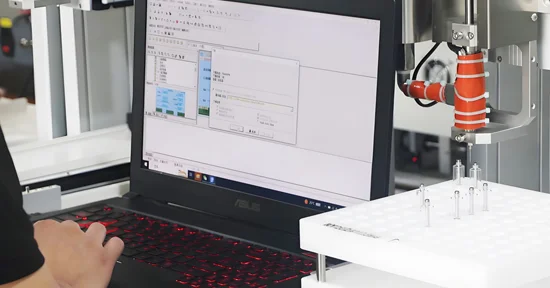

Jet Fueler by Vape-Jet

The Jet Fueler by Vape-Jet is a premium semi-automatic cartridge filler engineered for businesses aiming to increase production capacity without compromising on consistency. Combining speed, accuracy, and adaptability, this semi-automatic cartridge filler machine is a practical solution for medium-sized manufacturers looking to scale efficiently.

Production Speed: Streamlined Filling for Growing Businesses

Capable of filling 4,000 to 14,000 cartridges in an 8-hour shift, the Jet Fueler delivers exceptional throughput for a semi-automatic system. Its consistent pace helps manufacturers keep up with rising demand while reducing strain on personnel. By simplifying the filling workflow, this semi-automatic cartridge filling equipment helps minimize production bottlenecks, optimize resources, and maintain a smooth, efficient operation.

Precision & Accuracy: Consistent Dosing Every Time

In industries like CBD and vaping, precise dosing is crucial. The Jet Fueler’s advanced temperature management with PID control ensures minimal fluctuation, achieving a filling accuracy of ±0.01 mL. This guarantees uniform volumes in every cartridge, reducing product waste, maintaining batch-to-batch consistency, and supporting regulatory compliance. Whether working with distillates, rosins, or other delicate concentrates, this semi-automatic cartridge filler machine delivers dependable results that protect product quality.

Quality Control: Preserving Product Integrity

With a nitrogen-pressurized short oil path, the Jet Fueler minimizes oxidation and safeguards the quality of sensitive oils. This design preserves both the potency and flavor of the concentrates, ensuring that every cartridge meets high standards. For manufacturers focused on premium product quality, this semi-automatic cartridge filling equipment offers reliable protection throughout the filling process.

Ease of Use: Intuitive and Flexible Operation

The Jet Fueler is designed for operator convenience. Its intuitive control interface allows staff of varying experience levels to operate the machine efficiently, while the straightforward setup minimizes errors and training time. This user-friendly semi-automatic cartridge filler machine adapts well to both small-scale labs and larger production environments, offering operational flexibility without compromising control.

Versatility: Supports Various Concentrates and Cartridge Sizes

This semi-automatic cartridge filler accommodates a broad range of concentrates, including distillates and rosins, and can be used with multiple cartridge types thanks to interchangeable nozzles. Manufacturers can easily switch products or experiment with new formulations without the need for additional machines, saving space and capital investment while maintaining consistent production quality.

Best For: Medium-Sized Manufacturers Seeking Quality and Efficiency

The Jet Fueler is particularly suitable for medium-sized operations that value consistent quality and precise dosing. Its combination of high-speed throughput, exacting accuracy, and versatile design makes it an ideal semi-automatic cartridge filler machine for businesses expanding production while upholding product standards.

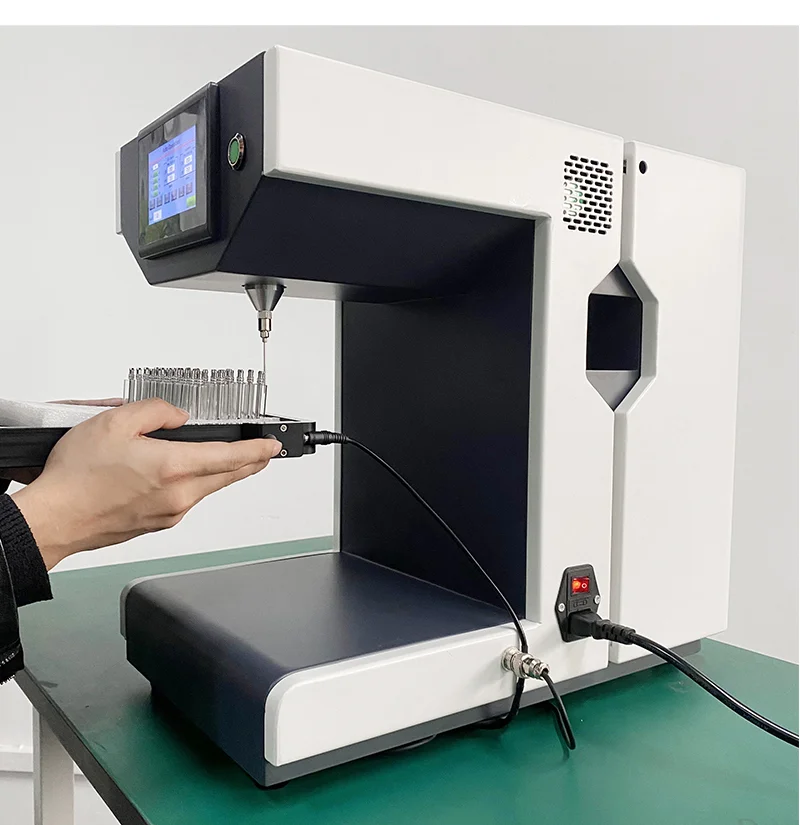

HotShot™ Pro by CoolJarz

The HotShot™ Pro is a modern semi-automatic cartridge filler engineered for manufacturers who need high output without taking up too much space. Known for its compact footprint and dependable performance, this semi-automatic cartridge filler machine is well-suited to small and medium-sized operations.

High Production Capacity: The HotShot™ Pro can handle up to 16,000 cartridges per 8-hour shift, making it one of the fastest semi-automatic cartridge filling equipment options for businesses that want to increase throughput while maintaining smooth operations.

Precision Design: With a short 185 mm oil path, the machine minimizes product degradation caused by repeated heating and cooling. This ensures accurate, consistent filling while preserving the quality of delicate concentrates.

Space-Saving Footprint: Requiring only 2 square feet of workspace, this semi-automatic cartridge filler allows small labs or production areas to maximize efficiency without sacrificing output.

Cost-Efficient: Compared to larger “big box” machines, the HotShot™ Pro provides high-speed performance at a fraction of the cost, making it a practical choice for manufacturers seeking both value and productivity.

User-Friendly Features: The machine includes a one-touch purge and clean function, a 1,000 mL reservoir, and an Anova precision heater to maintain consistent temperature control. These features make it easy for operators of any skill level to run and maintain the machine.

Best For: Manufacturers looking for fast, precise, and space-efficient semi-automatic cartridge filling equipment for small to medium production lines.

Cart Shooter by Viking Lab Supply

The Cart Shooter is an affordable semi-automatic cartridge filler designed for startups and small-scale operations. It delivers reliable performance without the high cost of larger semi-automatic cartridge filler machines.

Production Speed: Depending on operator skill and product type, it can fill 800 to 1,800 cartridges per hour, offering dependable output for businesses testing new markets or managing small production batches.

Versatility: This semi-automatic cartridge filling equipment works with high- and low-viscosity oils, multiple cartridge types, disposable vapes, and pods, allowing small manufacturers to produce a variety of products with one machine.

Ease of Operation: The Cart Shooter operates via a foot pedal and tray button, simplifying the filling process and reducing training time, which helps operators quickly achieve accurate and consistent results.

Affordability: Its lower price point makes it a cost-effective entry-level semi-automatic cartridge filling equipment option for startups, without compromising on reliability.

Best For: Small manufacturers or startups seeking budget-friendly semi-automatic cartridge filler solutions that remain practical and dependable.

SHARRB Cartridge Filler Syringe V2 by USA Lab

The SHARRB V2 is a compact, handheld semi-automatic cartridge filler designed for very small-scale or research-based production. Its portable design and precise dosing make it ideal for labs with limited space or those producing small batches.

Precision Dosing: The heated syringe system provides highly accurate small-batch filling, perfect for testing formulations or producing specialty cartridges.

Portability: Its handheld design allows operators to fill cartridges anywhere in the workspace, offering unmatched flexibility in small labs or mobile production setups.

Cost-Effective: Among semi-automatic cartridge filler machines, the SHARRB V2 is one of the most affordable options, allowing small operations or R&D teams to achieve precise dosing without heavy investment.

Best For: Very small-scale producers, laboratories, or R&D environments requiring accurate, customizable semi-automatic cartridge filling equipment.

Conclusion

Selecting the right semi-automatic cartridge filler depends on your production scale, product type, and budget.