Amount of oiling: 0.2-7ml

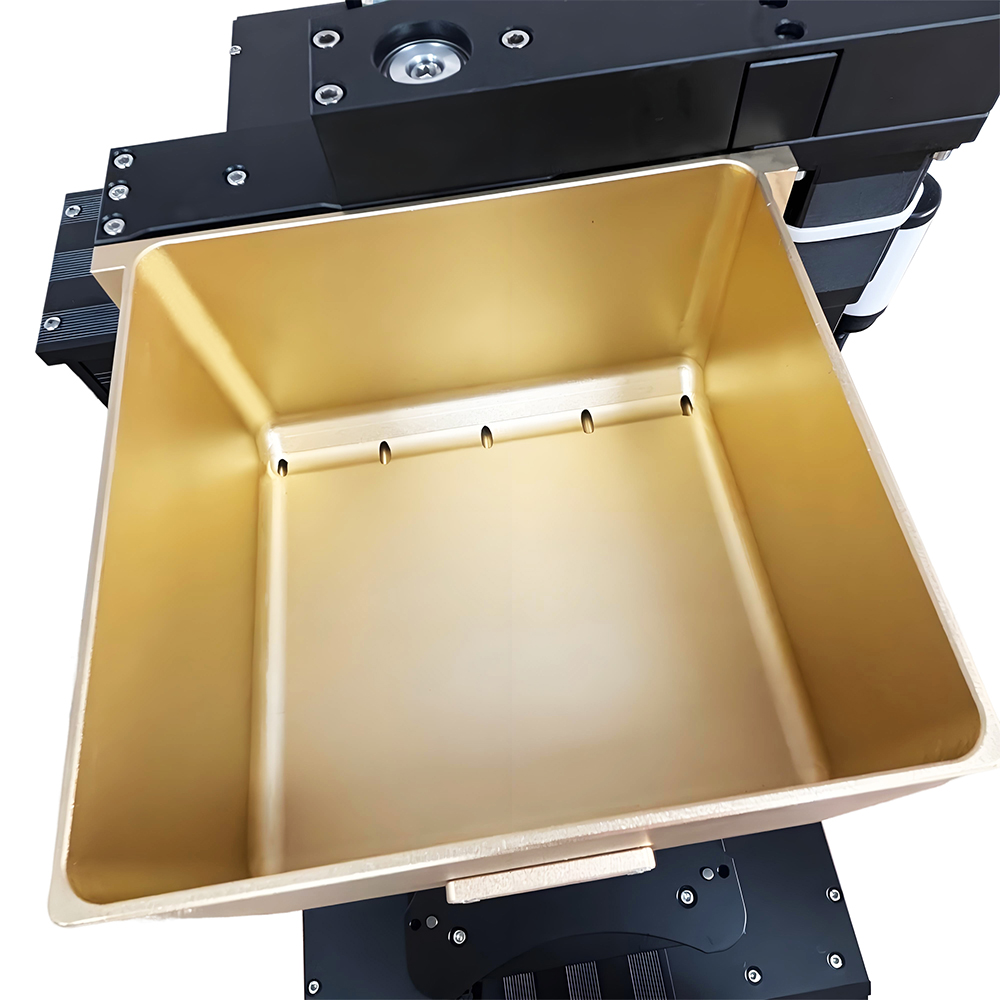

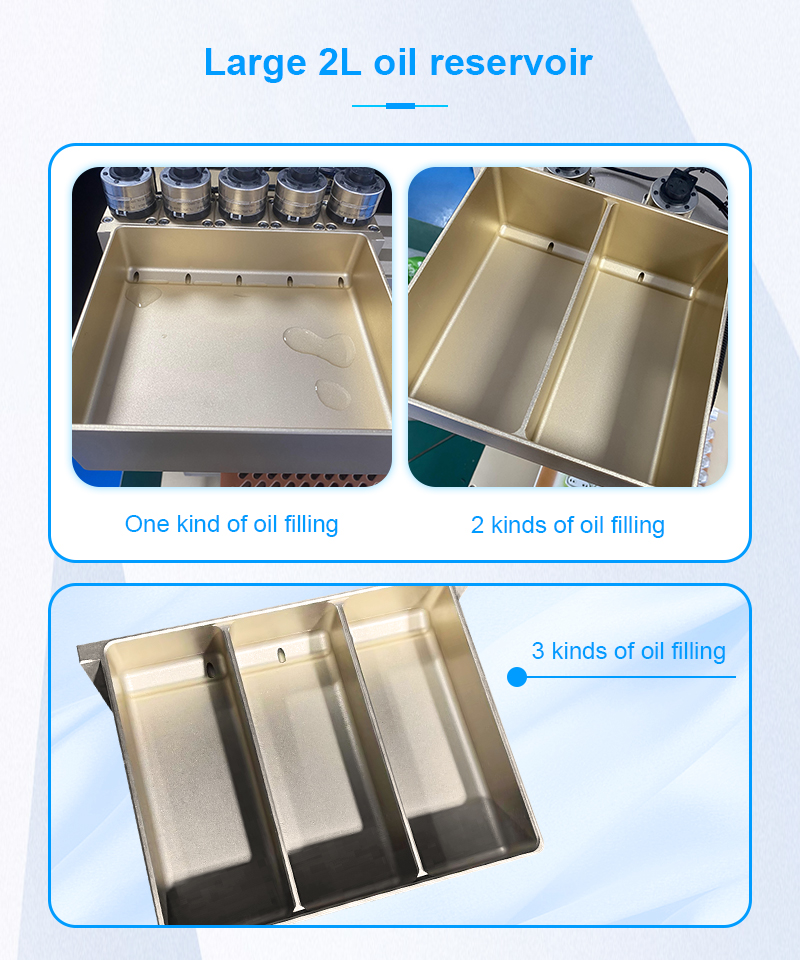

Oil basin: 2,5L

Oil filling accuracy: ±1%

Output: 2000-3000 sticks / hour

Power supply: AC220V/110V

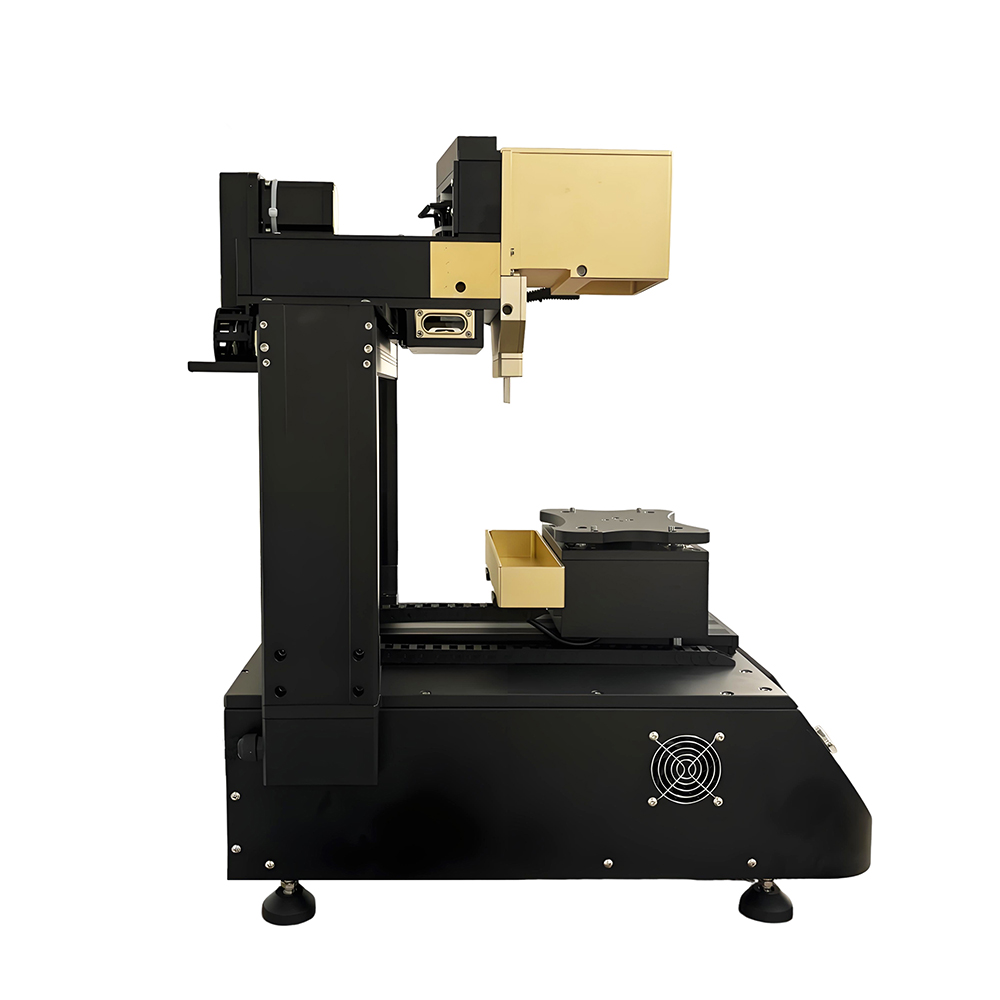

Drive mode: Stepper motor + rail drive

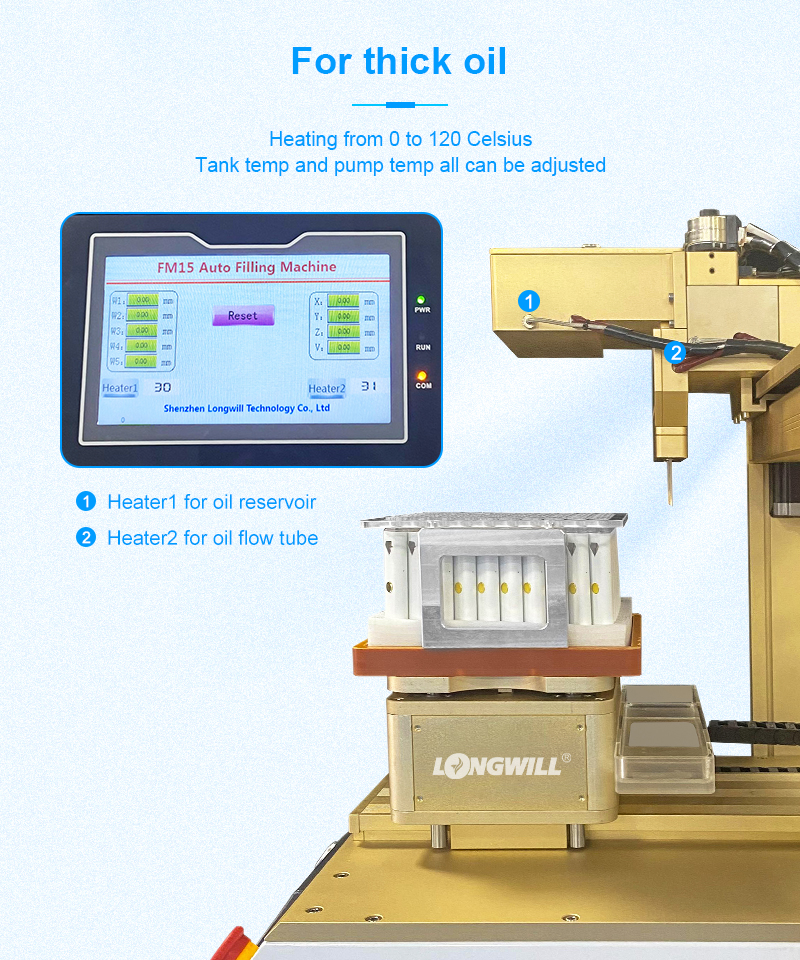

Temperature range: 0-120Celsius

Input Voltage: AC220V/110V

Key Feature: 5 Nozzles filling, High Productivity Short oil path, no clog Easy Operate Super stable

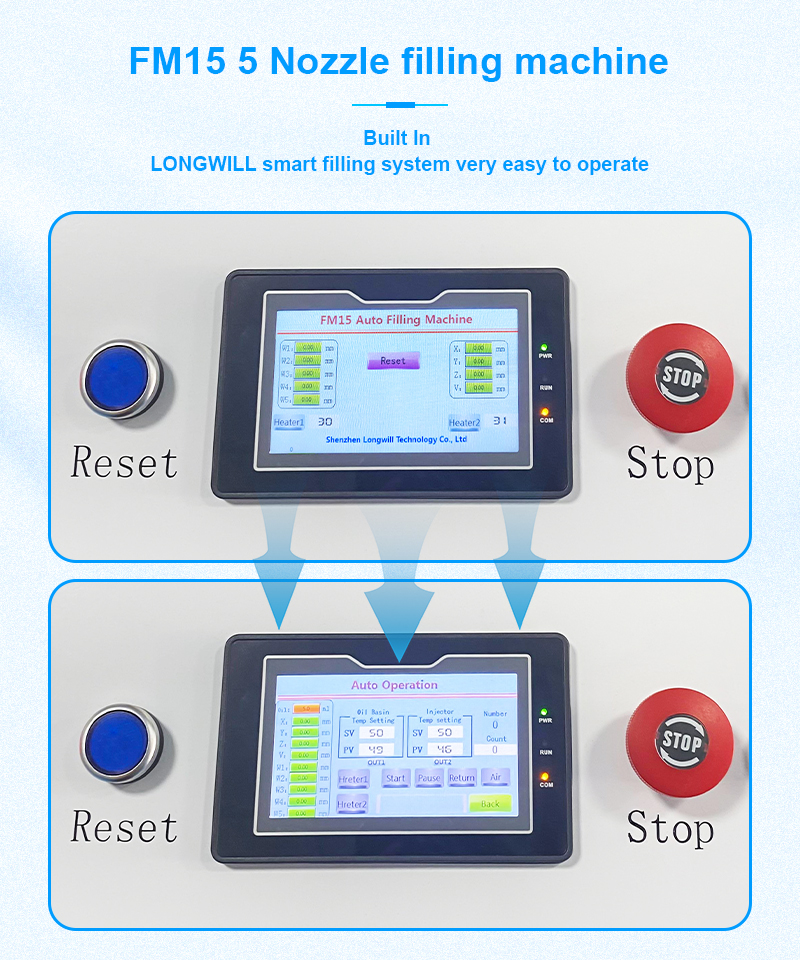

Panel control: Touch screen, operation button, emergency stop

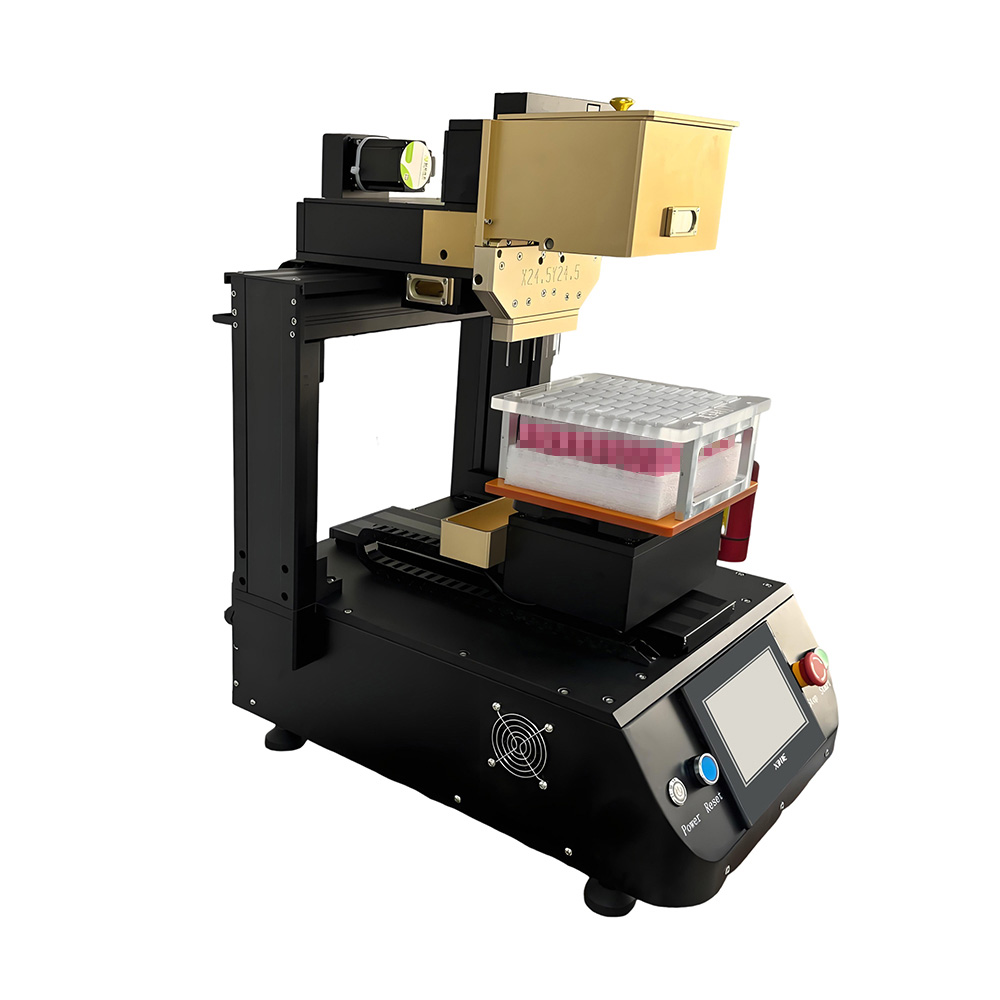

Top 1 CBD Automatic Cartridge Filling Machine

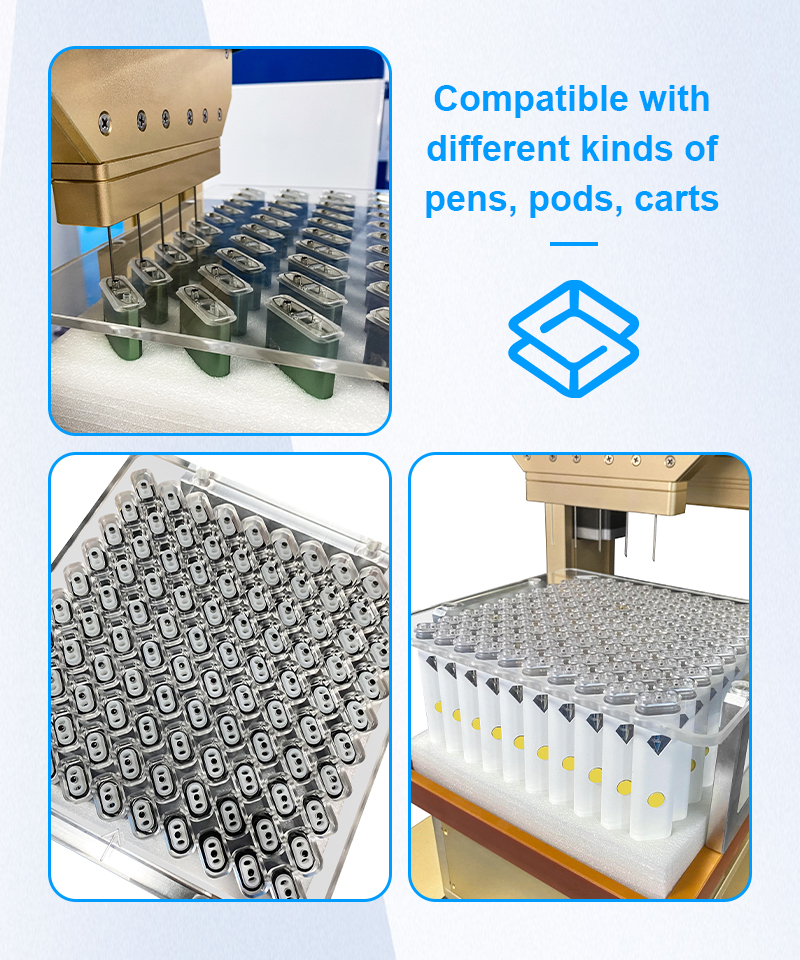

Boost your CBD production with the Top 1 Automatic Cartridge Filling Machine — the ultimate solution for fast, clean, and precise oil filling. Designed for disposable carts, disposable cartridges, and disposable pens, this advanced Cartridge Filling Machine offers a versatile 0.2–7ml filling range with ±1% accuracy. Its high-efficiency 5-head system delivers 2000–3000 units per hour, while the X/Y axis reaches speeds of 300 mm/s and the Z axis 200 mm/s, powered by a reliable stepper motor and rail drive for smooth, stable performance.

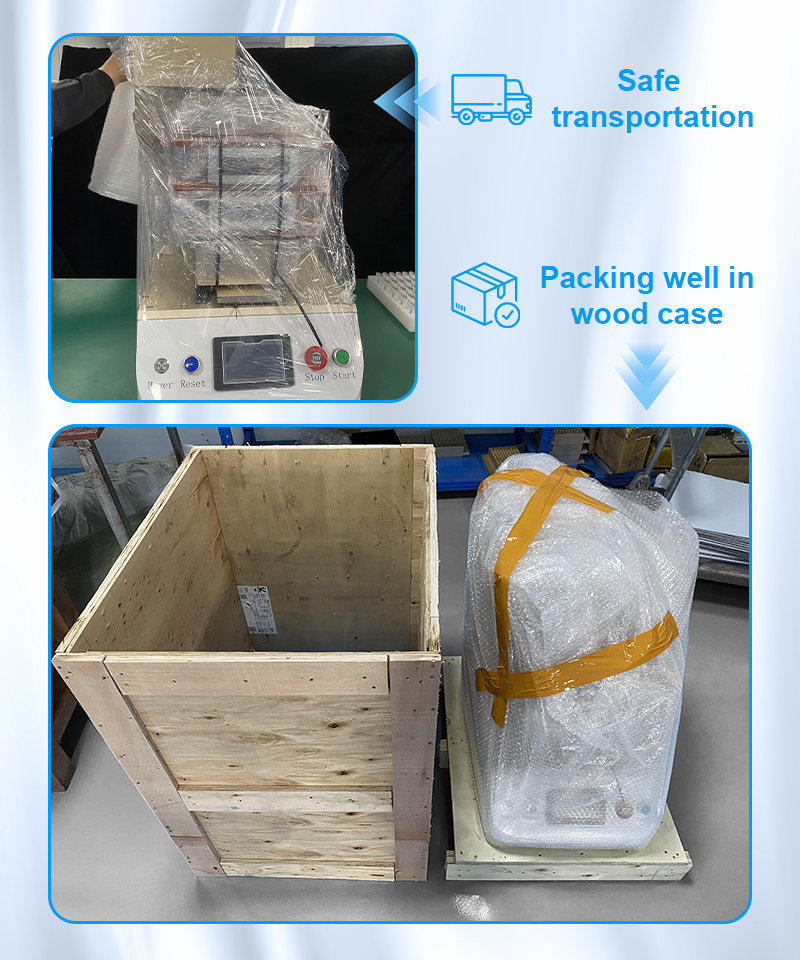

Equipped with an intelligent PLC control system, responsive touchscreen, and intuitive operation buttons, cartridge filling machine allows easy adjustments to position, oil injection, and speed, plus quick program selection based on PLC storage capacity. With flexible shipping options — DHL, FedEx, UPS, air, sea, or train door-to-door — and multiple payment methods via Alibaba, PayPal, T/T, Western Union, and more, it’s ready for global CBD manufacturers. If your business demands speed, precision, and consistency, the Longwill Automatic Cartridge Filling Machine delivers — cartridge after cartridge, pen after pen.

Longwill FM15 Automatic CBD Disposable Vape Pen Filling Machine: Precision Meets Productivity

The Longwill FM15 Automatic CBD Disposable Vape Pen Filling Machine is an advanced, high-performance solution engineered to meet the ever-growing demand for precise and efficient filling of CBD cartridges, disposable vape pens, and disposable carts. Designed specifically for thick CBD and THC distillate oils, this machine combines cutting-edge technology with user-focused features to deliver unmatched performance in cannabis oil filling applications.

CBD Cartridge Filling Machines Key Advantages & Features

High Efficiency for Scalable Production:

Equipped with 5 simultaneous filling nozzles, the FM15 can fill up to 2,500 units per hour, making it ideal for high-volume operations in both small startups and large-scale manufacturers. Whether you're working with CBD cartridge filling machines or expanding your disposable carts machine line, this model provides the speed and consistency required for fast-moving production environments.

The upgraded oil reservoir includes a transparent viewing window, allowing operators to easily monitor oil levels in real-time, reducing downtime and improving workflow.

Smart Filling System with Program Memory:

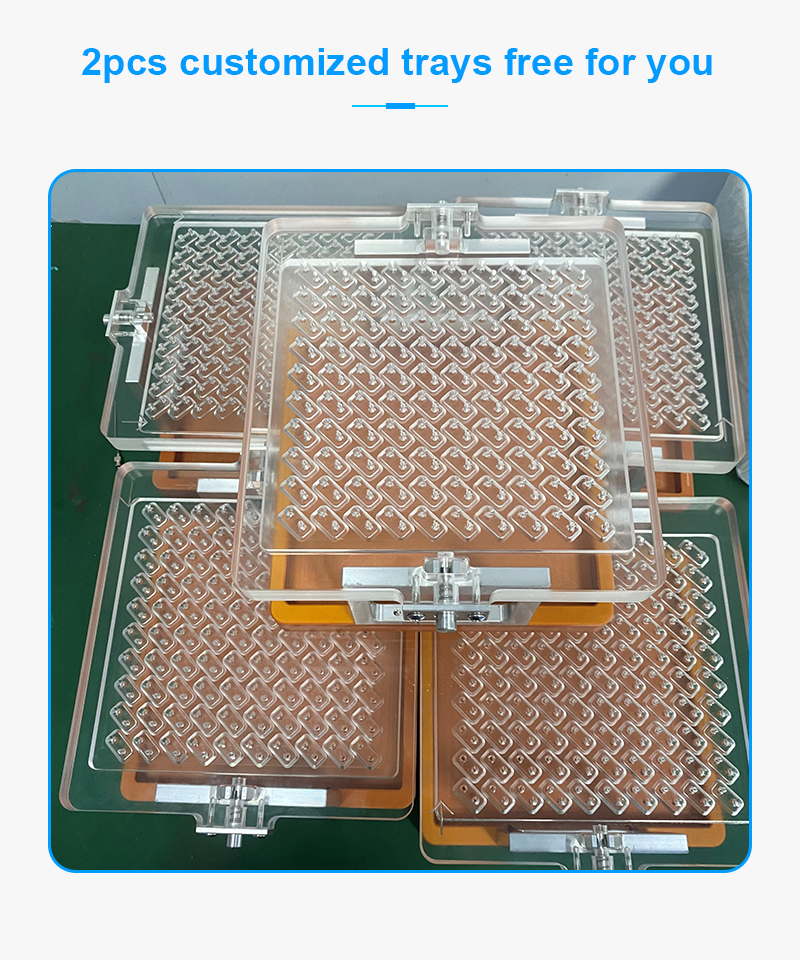

The FM15 is built with the proprietary Longwill Smart Filling System, capable of storing up to 10 customized filling programs for different product types and pen specifications. Whether you're switching between various CBD disposable pen models or filling carts of varying capacities, the system ensures efficiency with flexibility. Just select the desired program and start filling—no time wasted on recalibration.

User-Friendly Touchscreen Interface:

A large, intuitive touch panel enables easy operation, even for new users. All settings—temperature, fill volume, speed—can be adjusted with just a few taps. The design minimizes the training time required for operators and reduces the potential for user error, allowing teams to focus more on quality control and output.

Precision Filling for Thick Oils:

Unlike generic filling machines, the FM15 is specially optimized for high-viscosity CBD and THC distillate oils. Thanks to its precision-engineered internal components and temperature control features, the machine ensures ±1% filling accuracy, maintaining consistent dosages across all CBD cartridges and disposable vape pens. This level of consistency is essential in meeting industry standards and maintaining consumer trust.

Labor Cost Reduction & Operational Efficiency:

By automating the entire process, this CBD cartridge filling machine significantly reduces the need for manual labor. This leads not only to lower labor costs but also fewer human-related inconsistencies or errors during filling. For companies looking to scale profitably, automation is no longer optional—it's essential.

Customizable Parameters & Flexible Operation:

The FM15 supports adjustable settings for fill volume, speed, and temperature. This adaptability allows it to accommodate a wide range of oil types, viscosities, and container designs, from standard 0.5ml carts to 2ml disposables. The flexible architecture ensures seamless integration into your existing CBD filling line or production workflow.

Enhanced Quality Control Mechanisms:

Integrated sensors and monitoring systems ensure each cartridge or pen is filled accurately and sealed properly. Any deviation is detected and flagged in real-time, minimizing waste and enhancing batch-level quality assurance. Whether you're tracking production for internal QA or for external regulatory compliance, this machine has the capabilities built-in.

Compliance-Ready and Regulation-Friendly:

In the CBD and cannabis industries, regulatory compliance is critical. The FM15 supports data documentation, batch control, and consistent dosing—all of which are essential for meeting GMP standards, labeling regulations, and consumer safety guidelines in multiple global markets.

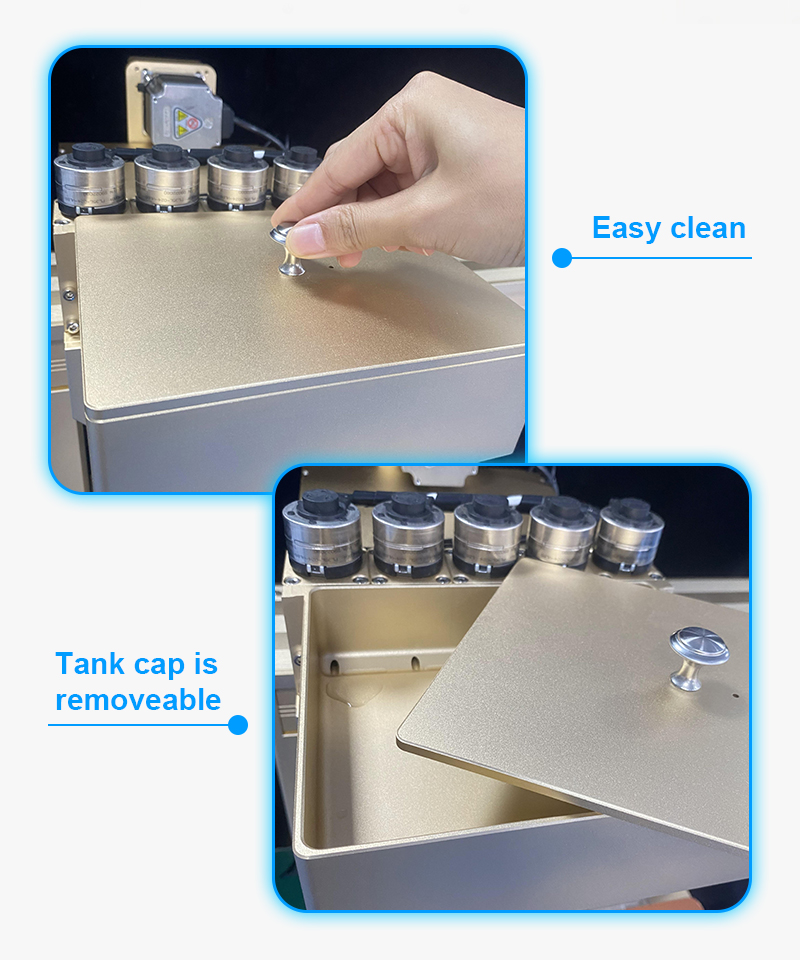

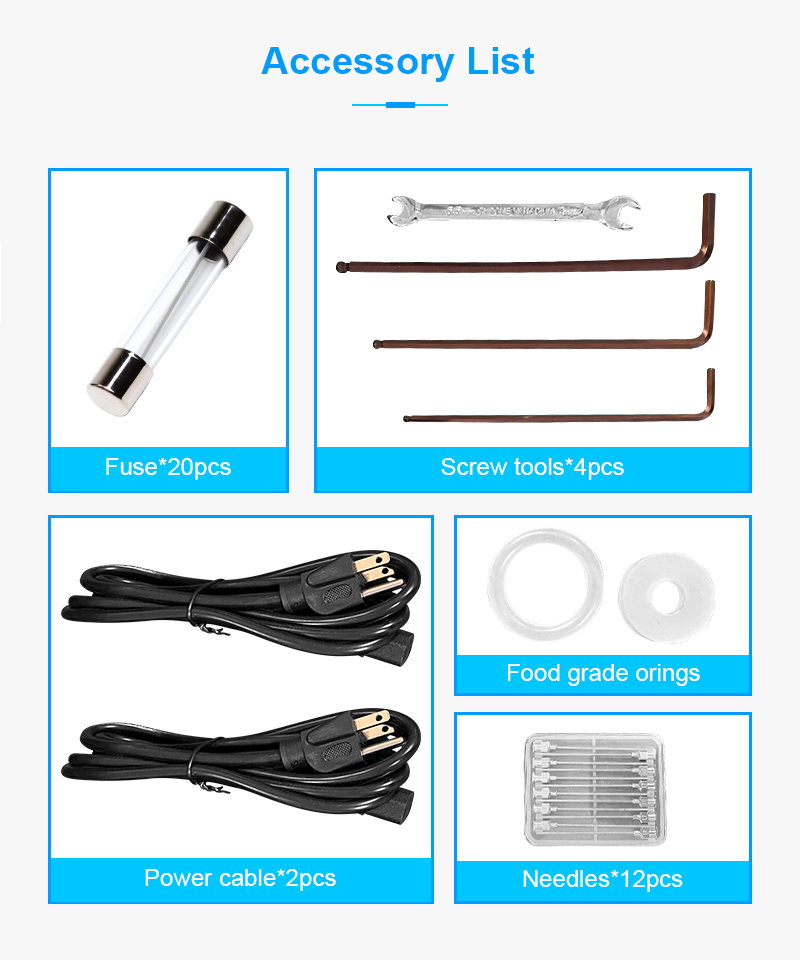

Hygienic, Durable Design for Cleanroom Use:

Manufactured using food-grade, corrosion-resistant materials, the FM15 features a hygienic design that’s easy to clean, sanitize, and maintain. This is crucial for companies operating under strict cleanliness standards or in regulated environments such as medical CBD product production.

Built for Growth – Fully Scalable:

Whether you're just starting out or looking to expand into high-output manufacturing, the FM15 scales with your business. It can be easily integrated into fully automated CBD cartridge filling and capping production lines, making it a future-proof investment that grows as your operations do.

Reliable Support & Fast Response:

We stand by the quality and reliability of every Longwill Automatic CBD Disposable Vape Pen Filling Machine. Should you have any questions, our professional service team is ready to assist within 24 hours. From setup guidance to after-sales service, we’re here to ensure your operation runs smoothly.

Curious about what other clients say ?

Our machines have been widely adopted by top-tier CBD brands across North America and Europe. Want to know how others are using the FM15 in real production environments?

Check below for client testimonials and application videos.